Low-interfacial-tension efficient oil-gas-water separation method and device

A technology of interfacial tension and separation method, which is applied in the direction of separation method, liquid separation, chemical instruments and methods, etc., can solve the problems of poor separation effect, complicated process flow, high dehydration cost and high temperature, and achieve size reduction, separation efficiency improvement, The effect of shortening the dehydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

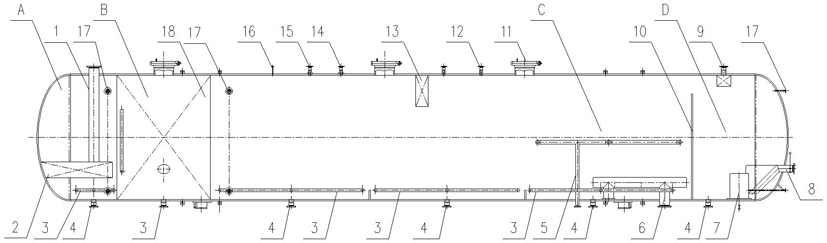

[0018]Example 1: As attachedfigure 1As shown, the low interfacial tension and high-efficiency oil-gas-water separation method is carried out according to the following steps: In the first step, the oil well gas-produced liquid mixture enters the water washing chamber A, and is pre-separated by the liquid distribution device below the water washing chamber A. The discharged gas flows above the water washing chamber A and enters the separation chamber C through the mist trapping net 13 to capture the liquid phase carried in the gas. The gas is discharged from the gas collecting bag 9 on the top of the oil chamber D; the second step is pre-separation When the discharged water-containing crude oil enters the coalescing chamber B and flows through the packing 18 in the coalescing chamber B, the fluid is forced to continuously change the velocity and flow direction, increasing the collision and coalescence probability of water droplets and water droplets, and oil droplets and oil droplets...

Embodiment 2

[0023]Example 2: As attachedfigure 1As shown, the device for implementing a low interfacial tension and high-efficiency oil-gas-water separation method includes a washing chamber A, a coalescing chamber B, a separation chamber C, and an oil chamber D. The right port of the washing chamber A is fixedly connected with the left port of the coalescing chamber B, The right port of coalescing chamber B is fixedly connected with the left port of separation chamber C, the right port of separation chamber C is fixedly connected with the left port of oil chamber D, and the liquid inlet pipe 1 is fixedly installed in the washing chamber A, and the top inlet of the liquid inlet pipe 1 extends To the outside of washing room A, the lower part of washing room A is equipped with liquid distributor 2. The bottom of liquid inlet pipe 1 is fixedly connected with the top inlet of liquid distributor 2, and the bottoms of washing chamber A, coalescence chamber B and separation chamber C are all fixed A s...

Embodiment 3

[0025]Example 3: As attachedfigure 1As shown, as an optimization of the above-mentioned embodiment 2, in-situ level gauges 7 are fixedly installed in the washing chamber A, the separation chamber C, and the oil chamber D.

[0026]According to the needs, install the in-situ level gauge 7 in the washing room A and the separation room C. On the one hand, it can automatically remind the replacement of the backwash packing 18 according to the liquid level difference, and on the other hand to prevent the gas phase from running out; install on-site in the oil chamber D Liquid level gauge 7, to prevent oil and gas in the gas phase; an oil-water interface regulator is installed in the separation chamber C to monitor the height of the oil-water interface. The height of the oil-water interface can be adjusted according to the different amount and water content of the incoming liquid to ensure the dehydration time and prevent water Emulsified oil is automatically collected in the separation chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com