Insulator dip-coating machine

A technology of dip coating machine and insulator, which is applied in the direction of coating and liquid coating device on the surface, which can solve the problems of paint splashing, waste of environment, pollution, etc., and achieve excellent hydrophobic migration, smooth surface and high coating thickness. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

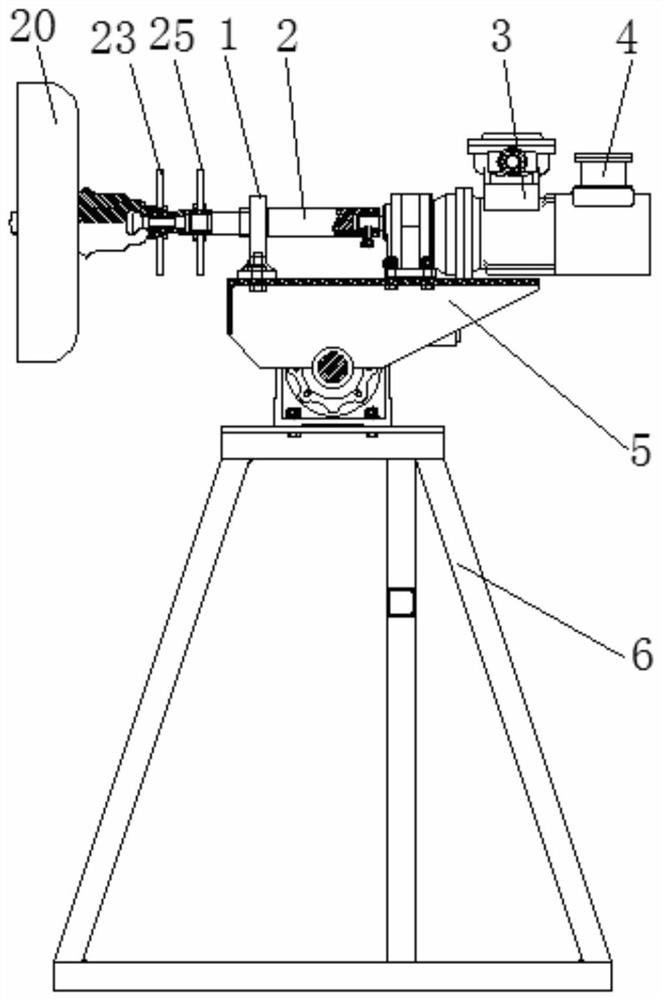

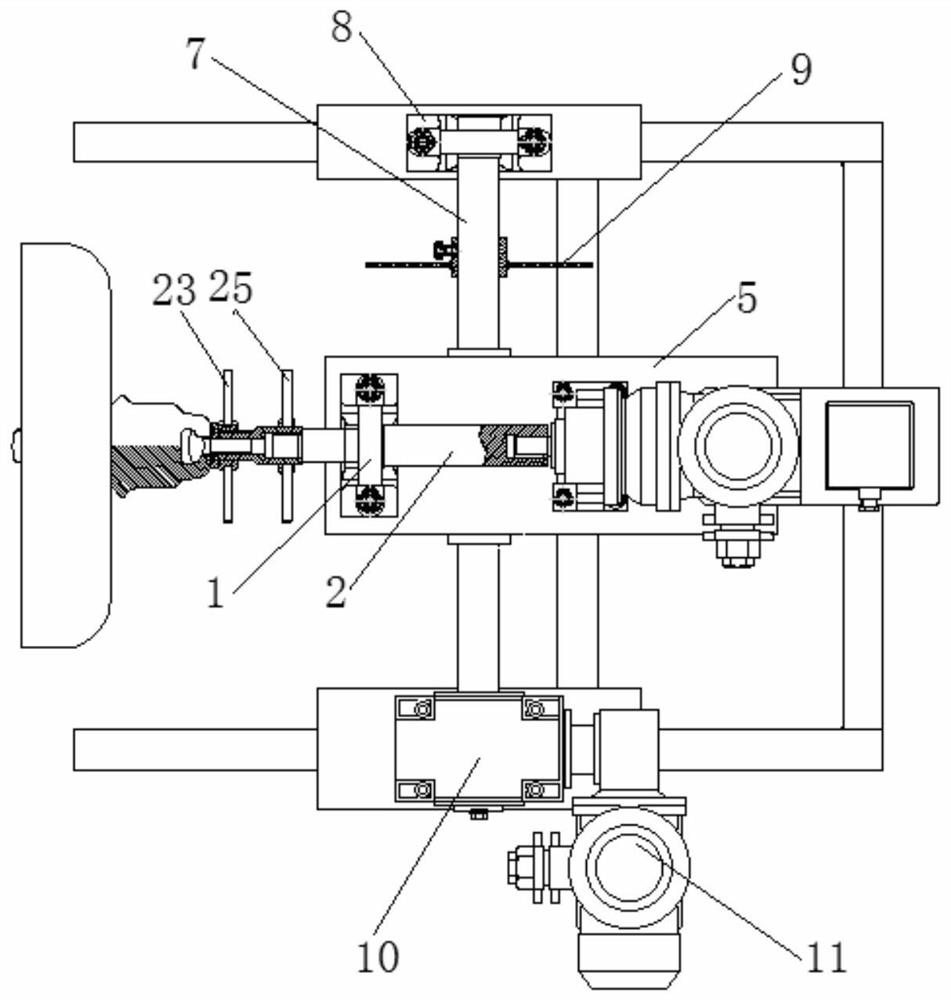

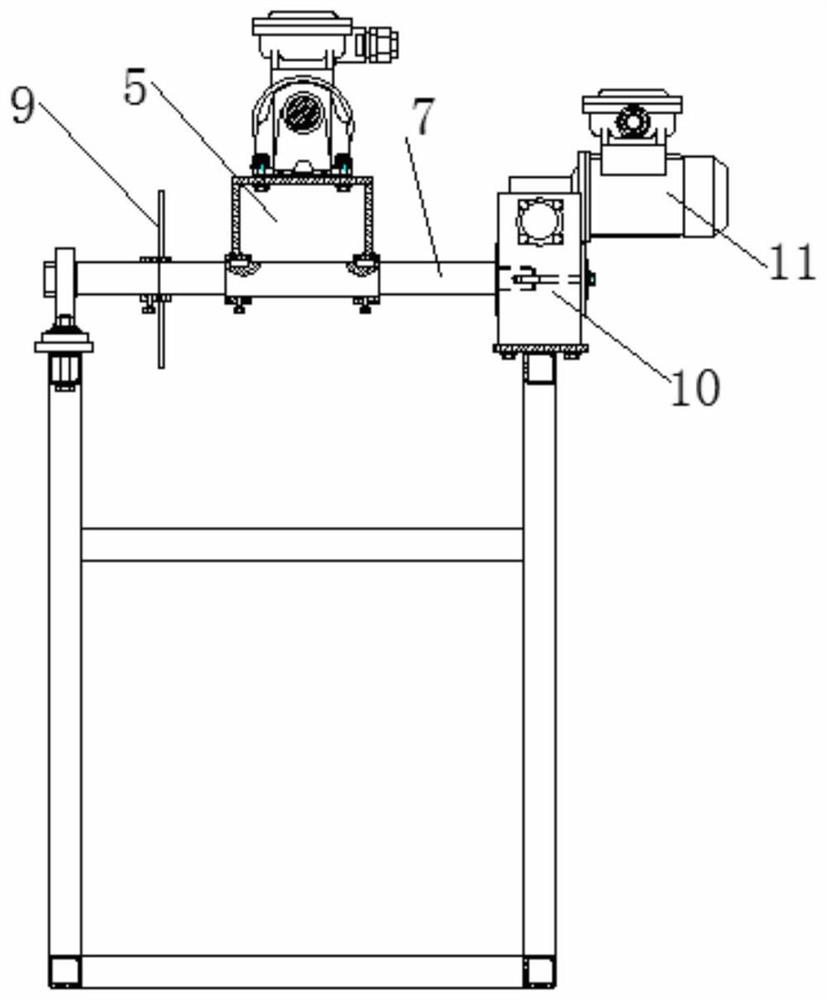

[0012] like Figures 1 to 3 As shown, an insulator dip coating machine of the present invention includes: a frame 6, a rotating base 5, a main shaft 2, a rotating shaft 7, a first bearing seat 1, a second bearing seat 8, a first reducer 3, a frequency conversion Speed-regulating motor 4, second speed reducer 10 and three-phase asynchronous motor 11. The second bearing seat 8 is fixed on one side of the frame 6, and the second reducer 10 is fixed on the other side of the frame 6. One end of the rotating shaft 7 is loaded into the second bearing seat 8, and the other end is connected to the second reducer. The output shaft of the machine 10, the three-phase asynchronous motor 11 is fixed on the frame 6, and the output shaft of the three-phase asynchronous motor 11 is connected to the input shaft of the second reducer 10. The rotating base 5 is fixed on the middle part of the rotating shaft 7, the first bearing seat 1 is fixed on one end of the rotating base 5, the first reducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com