Multi-water-channel hot stamping die

A technology of hot stamping dies and water channels, applied in the field of hot stamping, which can solve the problems of small plastic deformation range, difficulty in controlling the temperature of molds and stamping parts, and decreased dimensional stability of stamping parts, so as to avoid unstable mechanical properties, sufficient and uniform Effect of cooling and avoiding large amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

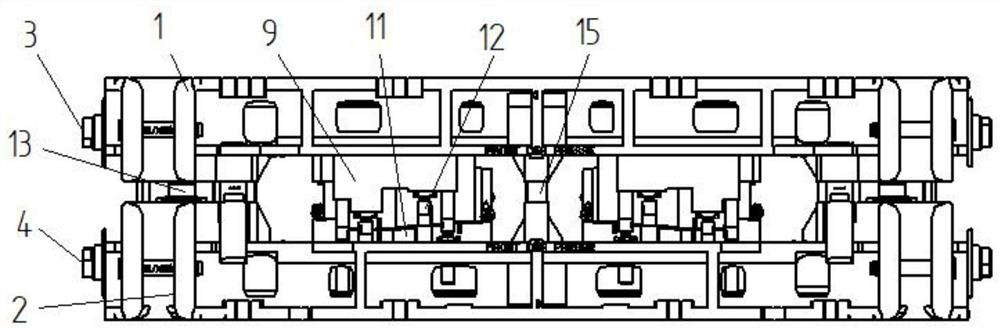

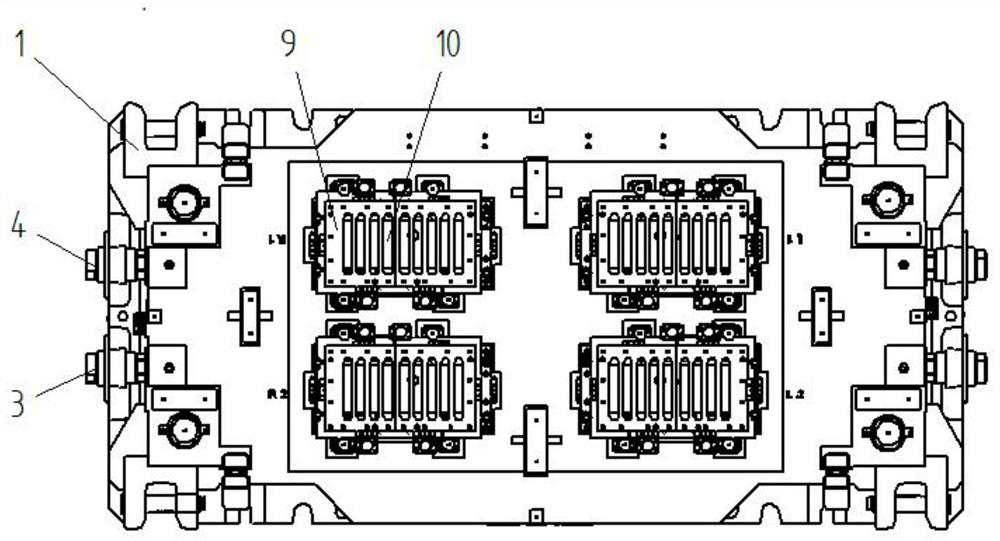

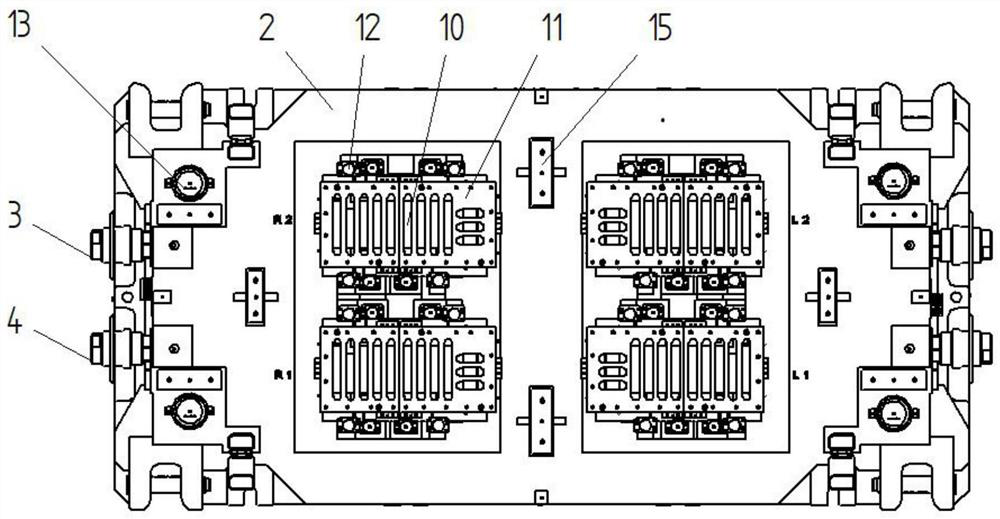

[0024] see Figure 1 to Figure 5 , a multi-channel hot stamping die, comprising an upper mold base 1, an upper mold insert 9, a lower mold base 2 and a lower mold insert 11; both the upper mold base and the lower mold base are provided with a main water channel, and the main water channel is provided with A plurality of cavities 17, the arrangement of multiple cavities in the main water channel is not a single straight line, there are water outlets 14 connected between each cavity, and a plurality of small water channel holes 5 are provided in each cavity; The mold insert is set on the upper mold base, and the upper mold insert is provided with a cooling channel, and the cooling channel of the upper mold insert is connected with the small hole of the main ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com