A vacuum brazing method for workpiece joints based on strength compensation

A technology of strength compensation and brazing method, applied in the field of precision workpiece processing, can solve the problem of low strength of welding parts, and achieve the effect of ensuring strength, increasing service life and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

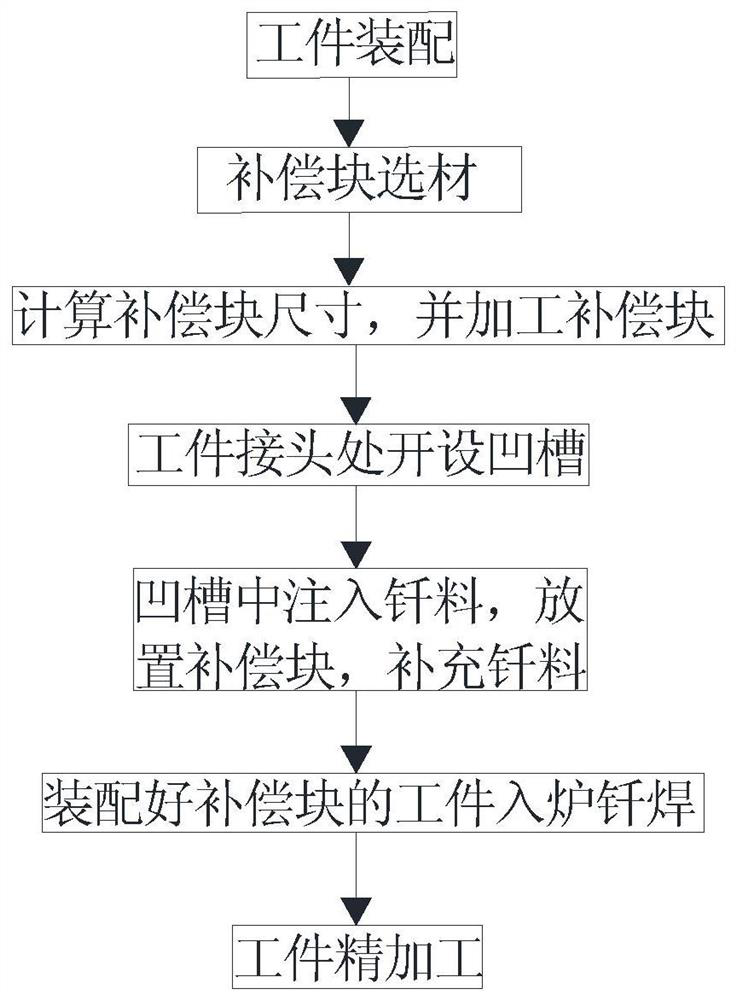

[0040] A vacuum brazing method for workpiece joints based on strength compensation, such as figure 1 shown, including the following steps:

[0041] a. Assemble the two workpieces to be processed or repaired so that the contact surfaces of the two are flush; ensure that the misalignment distance error is within 0.05mm;

[0042] b. Determine the material of the compensation block according to the materials of the two workpieces;

[0043] When the two workpieces are of the same material, the compensation block shall be of the same material as the workpiece;

[0044] When the materials of the two workpieces are different, the material of the compensation block is determined according to the difference in the thermal expansion coefficients of the two workpieces: the difference in the expansion coefficients of the two workpieces is greater than 5×10 -6 / °C, the compensation block adopts a material with an expansion coefficient between the two workpieces; the difference between the...

Embodiment 2

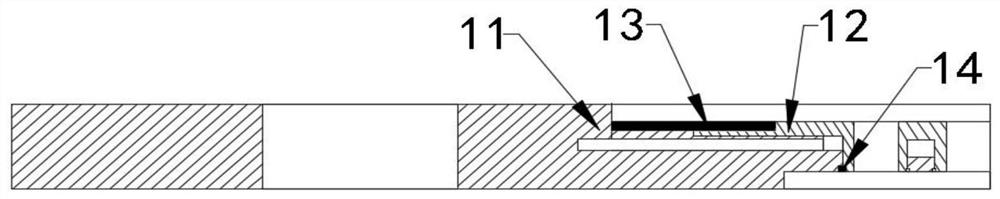

[0059] in processing such as image 3In the cooling water chamber shown, since the first workpiece 11 is made of stainless steel and the second workpiece 12 is made of high-strength copper alloy, there are two joints between them, and both joints are butt joints. Add compensation block 13 and compensation block 14 respectively to vacuum weld the joints of the two workpieces; the specific steps are as follows:

[0060] a. Assemble the first workpiece 11 and the second workpiece 12, and use bolts and burrs for positioning, so that the contact surfaces of the two are flush; ensure that the misalignment distance error is within 0.05mm;

[0061] b. Determine the material of the compensation block according to the materials of the two workpieces;

[0062] Since the materials of the first workpiece 11 and the second workpiece 12 are different, and the difference between the coefficients of thermal expansion of the two workpieces is less than or equal to 5×10 -6 / °C, therefore, the ...

Embodiment 3

[0077] In maintenance such as Figure 4 In the shown device, there is a vacuum brazed annular butt joint between the third workpiece 21 and the fourth workpiece 22, wherein the material of the third workpiece 21 is stainless steel, and the material of the fourth workpiece 22 is a reinforced superalloy. Increase the compensation ring 23 to weld the joints of the two workpieces; the specific maintenance steps are as follows:

[0078] a. Assemble the third workpiece 21 and the fourth workpiece 22 so that the contact surfaces of the two are flush; ensure that the misalignment distance error is within 0.05mm;

[0079] b. Determine the material of the compensation ring 23 according to the materials of the two workpieces;

[0080] Since the materials of the third workpiece 21 and the fourth workpiece 22 are different, and the difference between the coefficients of thermal expansion of the two workpieces is less than or equal to 5×10 -6 / °C, therefore, the compensating ring 23 is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com