Self-centering lathe center frame

A center frame, self-centering technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of difficult installation of machine tools, troublesome workpiece adjustment, small clamping range, etc., to achieve good performance, The effect of saving time for loading and unloading workpieces and increasing the clamping range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

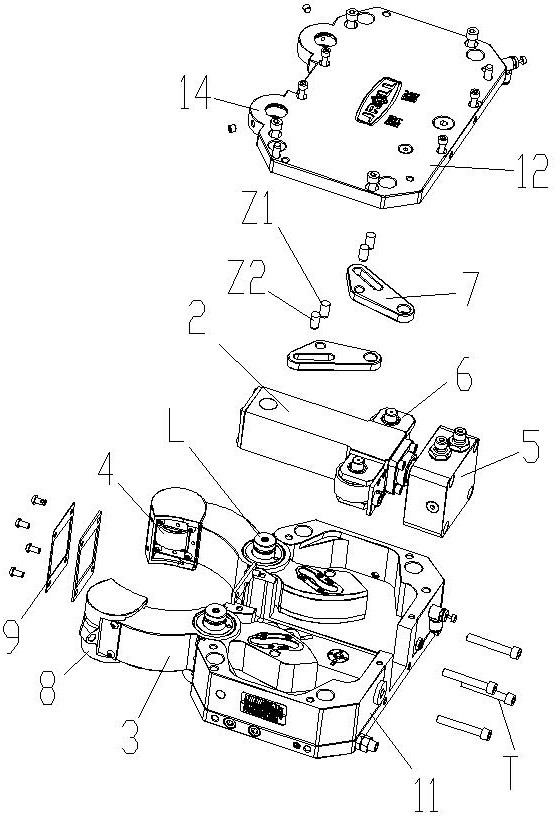

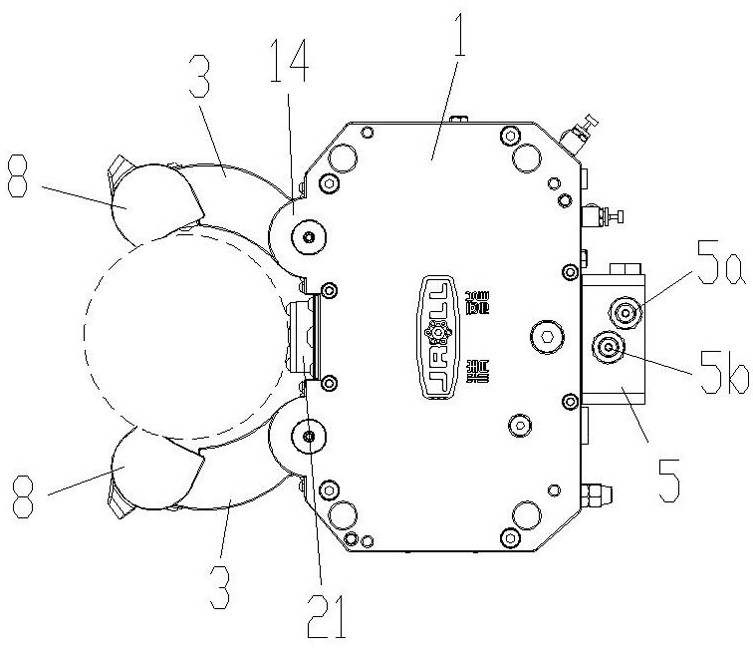

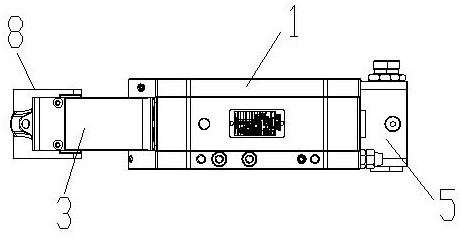

[0024] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] Figures 1 to 9 It is the schematic diagram of construction and wall pile of the present invention.

[0026] The reference signs are: rotating shaft L, connecting bolt T, first pin Z1, second pin Z2, shell 1, assembly cavity 1a, rear notch 1b, main shell 11, cover plate 12, right support ear 13. Left support ear 14, oil cylinder 2, center arm 21, support arm 3, arc-shaped rolling surface 3a, second slideway 31, second pin hole 32, support wheel set 4, support wheel 41, safety valve 5, Oil inlet 5a, oil outlet 5b, roller group 6, roller seat 61, roller shaft 62, roller 63, return plate 7, reaming hole 7a, first slideway 7b, first pin hole 7c, iron dust protection windshield 8. Connecting hole 8a, spray hole 8b, locking block 81, pressure plate 9.

[0027] Such as Figure 1 to Figure 9 As shown, the present invention provides a kind of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com