Mechanical arm control method based on model design

A technology of model design and control method, applied in the direction of manipulator, program control manipulator, claw arm, etc., can solve the problems of repeated debugging and error-prone development, and achieve the effect of increasing experimental safety, reducing development cost and simplifying the programming process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

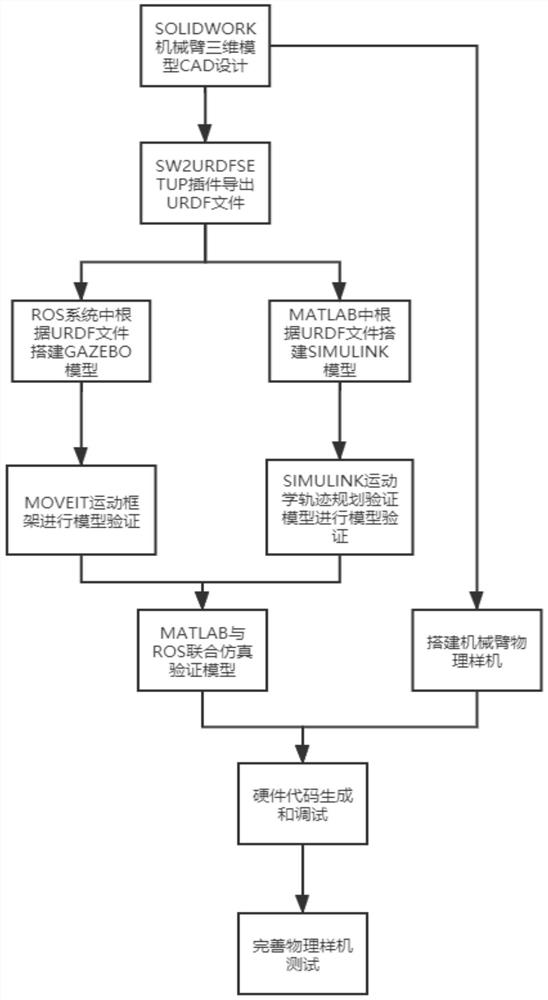

[0037] The present invention is a kind of mechanical arm control method based on model design, such as figure 1 As shown, the specific steps are as follows:

[0038] Step 1. In the model design stage, according to the purpose and function of the manipulator, use SOLIDWORK software to design the 3D model of the manipulator to obtain the CAD file;

[0039] Step 1 is specifically implemented according to the following steps:

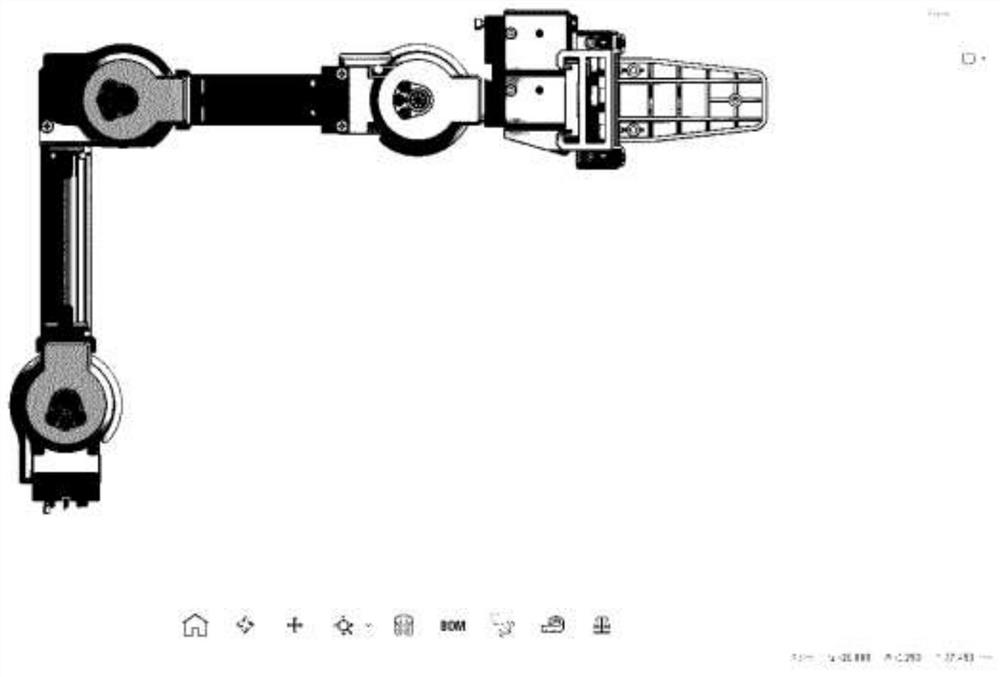

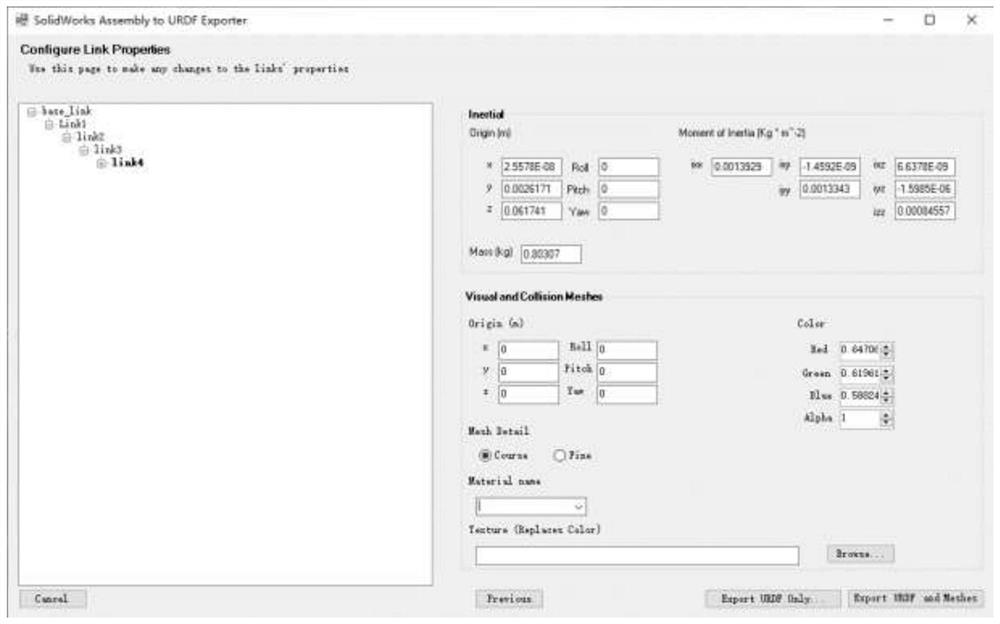

[0040] Step 1.1. According to the purpose and functional requirements of the manipulator, design the 3D model CAD file of the manipulator through SOLIDWORK software, such as figure 2As shown, and determine the hardware selection of the robot, mainly the selection of drivers and processors and sensors. In general, the bus servo is selected for the driver, the DSP controller is selected for the processor, the processor h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com