Finished feed product stacking equipment

A finished product and palletizing technology, which is applied in the field of palletizing equipment for finished feed products, can solve problems such as inconvenient adjustment of the inclination angle of the conveying mechanism, insufficient stability of feed packaging bags and collapse, and uncontrolled falling of feed, so as to achieve stable stacking, avoid easy collapse, and facilitate The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

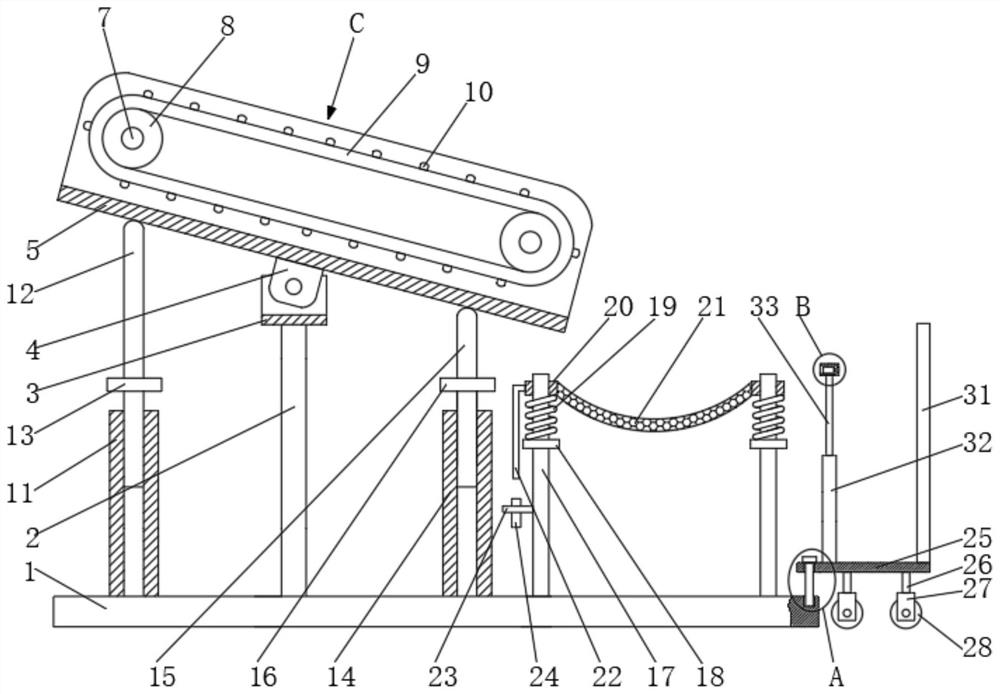

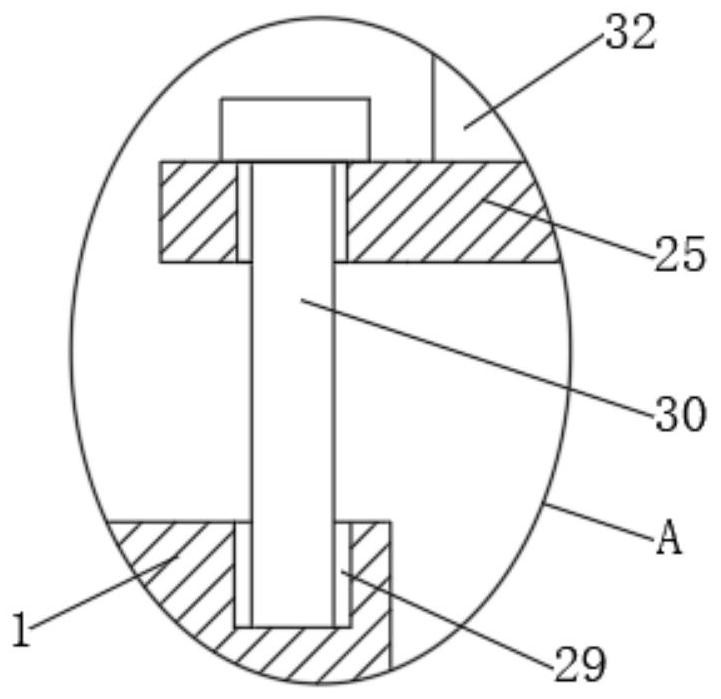

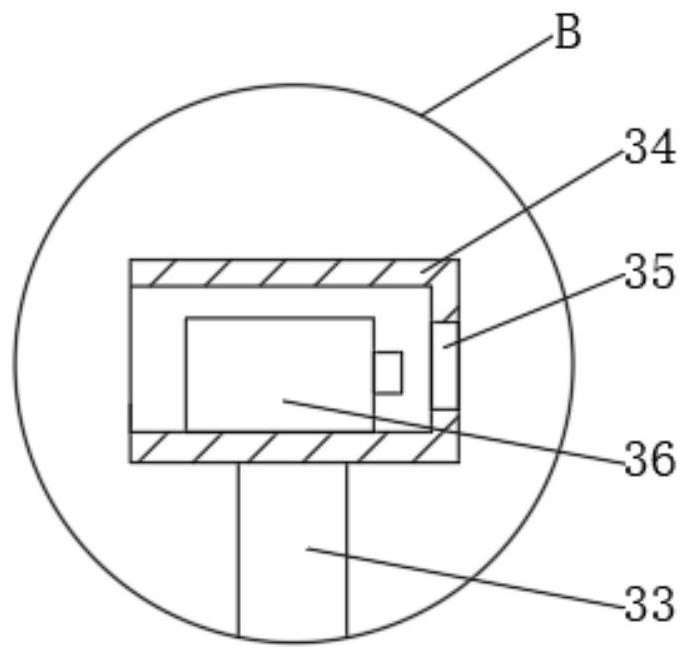

[0024] During specific implementation: if Figure 1 to Figure 6 As shown, a palletizing equipment for finished feed products includes a base 1 and a support plate 25, the upper end of the base 1 is fixedly connected with a support column 2, and the upper end of the support column 2 is fixedly connected with a shaft frame 3, and the shaft frame 3 is hinged with a hinged seat 4, the upper end of the hinged seat 4 is fixedly connected with a frame 5, the outside of the frame 5 is fixedly mounted with a drive motor 6, and the motor shaft 7 of the drive motor 6 rotates with the frame 5 connected, the outer side of the motor shaft 7 is fixedly installed with a driving roller 8, and the outer side of the driving roller 8 is covered with a conveyor belt 9;

[0025] The upper end of the base 1 is fixedly connected with a column 17, the outer side of the column 17 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com