Portal-type double-bucket-wheel blending stacking and blending reclaiming integrated machine and operating method thereof

A double-bucket wheel and integrated machine technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of low utilization efficiency, high overall weight of equipment, and large stockyard width, so as to reduce the cost of later use and maintenance, and reduce the once Sexual investment cost, width and height increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

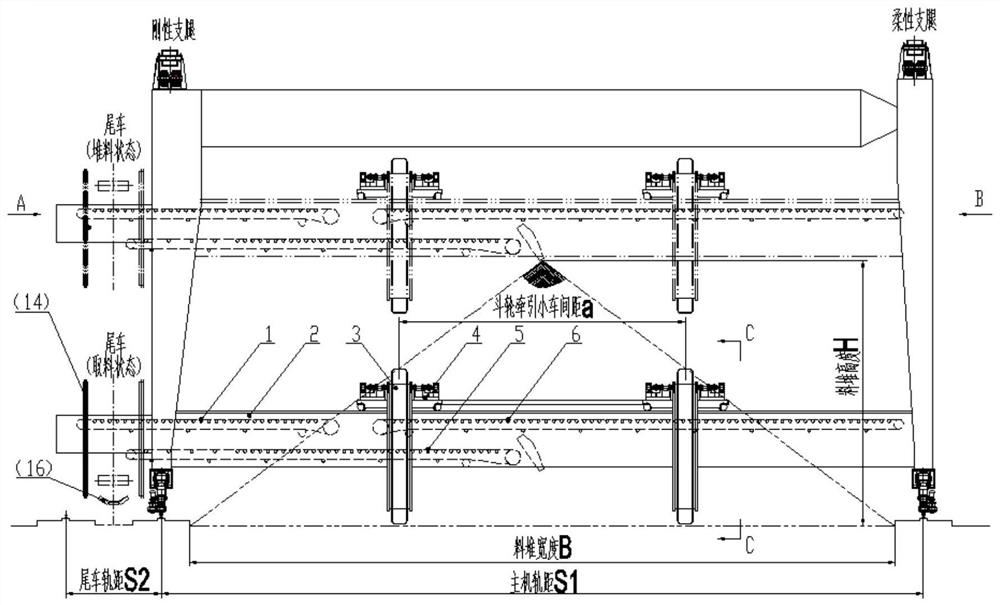

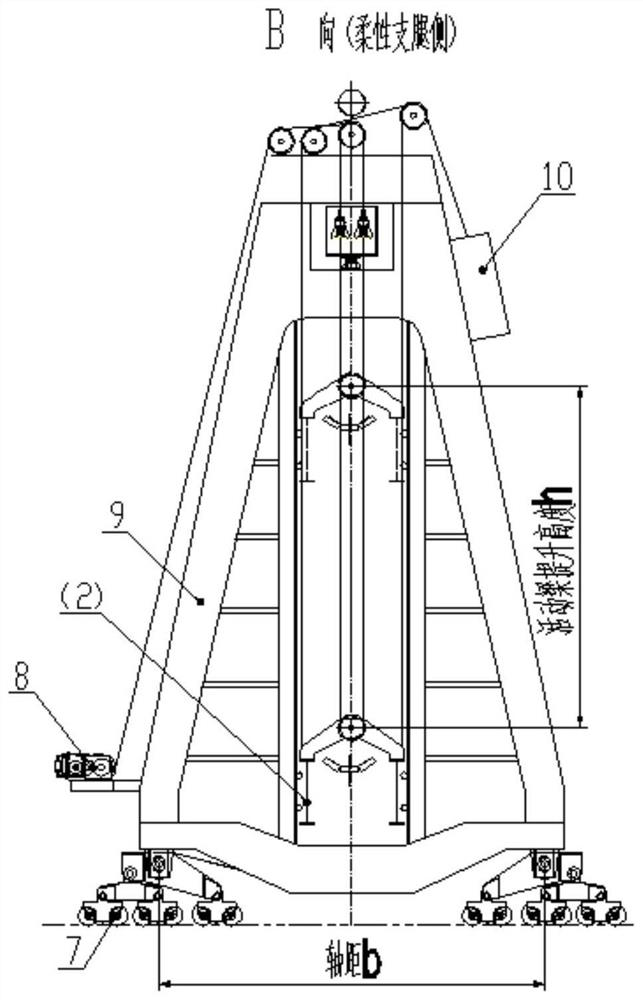

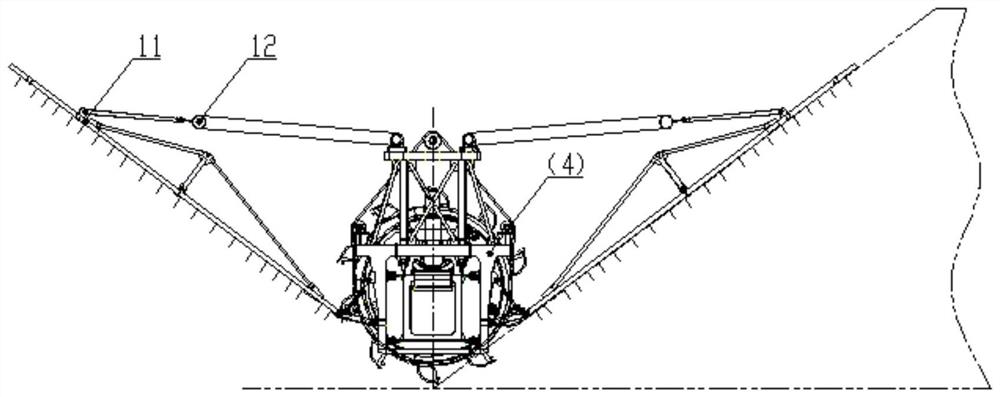

[0078]Such asFigure 1-5As shown, a door-type double bucket wheel mixing, stacking, mixing and reclaiming integrated machine consists of a first fixed belt conveyor 1, a movable beam 2, a bucket wheel device 3, a traction trolley 4, and a second fixed belt conveyor 5. The third fixed belt conveyor 6, the main machine traveling device 7, the movable beam lifting and hoisting mechanism 8, the mast device 9, the movable beam lifting and hoisting mechanism counterweight 10, the material rake device 11, the material rake device hoisting mechanism 12, the semi-lying movable sheet The tail car 13, the stacking and picking state conversion mechanism 14, the semi-lying single tail car movable main beam 15, the ground belt conveyor system 16 and the tail car running device 17.

[0079]The lower part of the material rake device 11 is connected to the traction trolley 4, and the upper part is connected to the material rake device hoisting mechanism 12, and the material rake device hoisting mechanis...

Embodiment 2

[0091]The working method of the gantry double-bucket wheel mixing, stacking and mixing and reclaiming integrated machine that integrates stacking and reclaiming functions includes the following steps:

[0092]1. The central control room issues instructions for stacking or reclaiming working status to make the equipment in a certain (stacking or reclaiming) working state.

[0093]2. After stacking or reclaiming, the equipment is restored to its original state.

[0094]In step 1, when the portal double bucket wheel mixing stacker and reclaimer is in stacking working state, it includes the following steps:

[0095]The movable main beam 15 of the semi-lying single-trailer is in the upper position, that is, the stacking state. during this process,

[0096](1) The movable beam 2 moves up to the uppermost end synchronously under the action of the movable beam lifting and hoisting mechanism 8.

[0097](2) Start the second fixed belt conveyor 5 and press itfigure 1 Shows clockwise rotation.

[0098](3) Start the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com