Etching solution composition

A technology of etching solution and composition, which is applied in the manufacture of display devices, the field of etching solution composition of copper film and molybdenum film, can solve the problems of increased critical dimension loss, incomplete step coverage, poor data opening, etc., and achieve high Number of sheets to be processed, long shelf life, over-etching suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 13 and comparative example 1 to comparative example 9

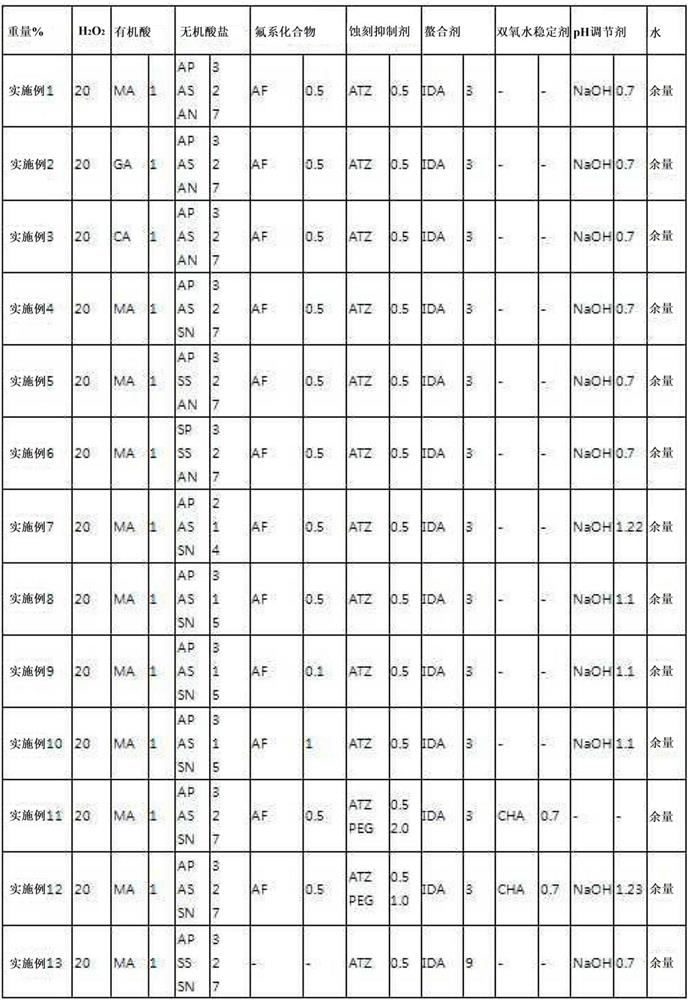

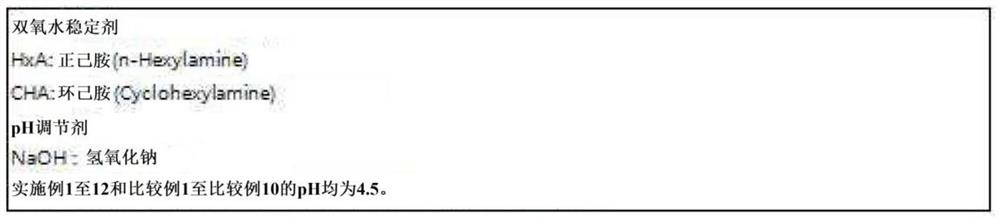

[0134] An etching solution composition (100 g) was prepared according to the components and contents described in Table 1 below.

[0135] 【Table 1】

[0136]

[0137]

[0138]

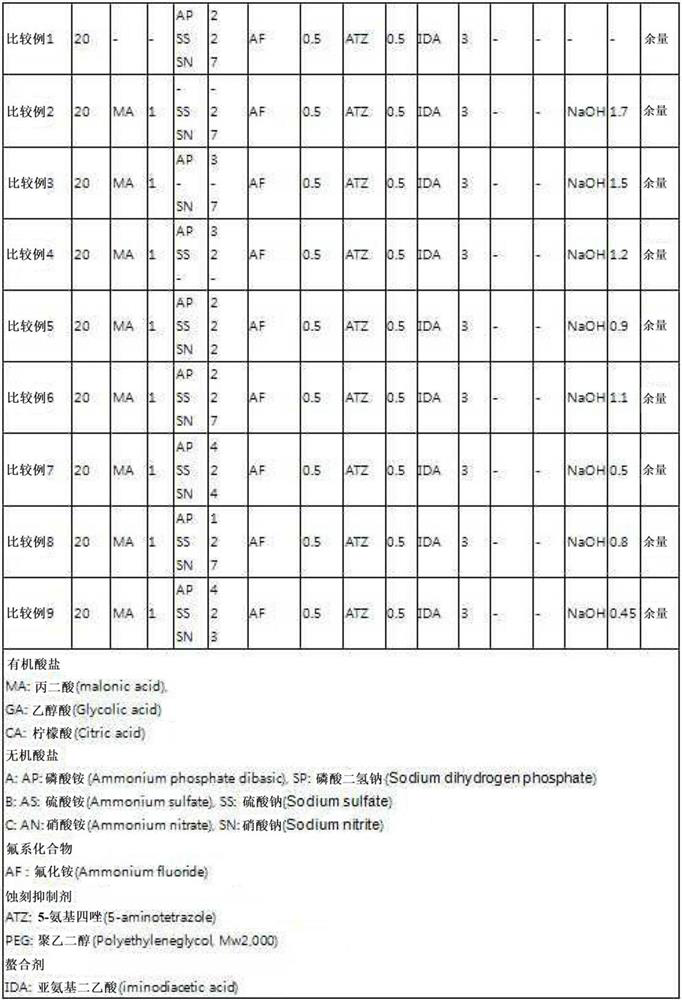

[0139] 【Table 2】

[0140]

[0141]

[0142] 【table 3】

[0143]

[0144] As shown in the above-mentioned Table 2, it was confirmed that the etching solution composition according to the present invention simultaneously etches the copper film and the molybdenum-containing film together, and can achieve a suitable etching rate and etching deviation. In addition, it was confirmed that a good taper angle and linearity can be achieved even when they are etched together.

[0145] It was confirmed that the etching liquid composition according to the present invention can achieve a remarkable etching rate for the copper film despite having a pH of 4 or more. In addition, it was confirmed that a better taper angle can be formed as the fluorine-based compound is further included.

[0146] Fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com