Offshore bridge erecting machine and construction method thereof

A construction method and bridge erecting machine technology, applied in erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as slow construction progress, high construction cost, and short continuous operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present invention is based on the construction conditions of a finger-type wharf for an actual project, and carries out a series of studies on refitting the bridge erecting machine to form a complete set of construction methods for the superstructure of the high-pile wharf. Considering comprehensive requirements and construction schedule, special equipment is used for construction. This embodiment mainly elaborates on the design of special equipment, assembly and load test requirements, the process of lifting and installing concrete prefabricated parts, and the key points of mobile and in-place construction technology.

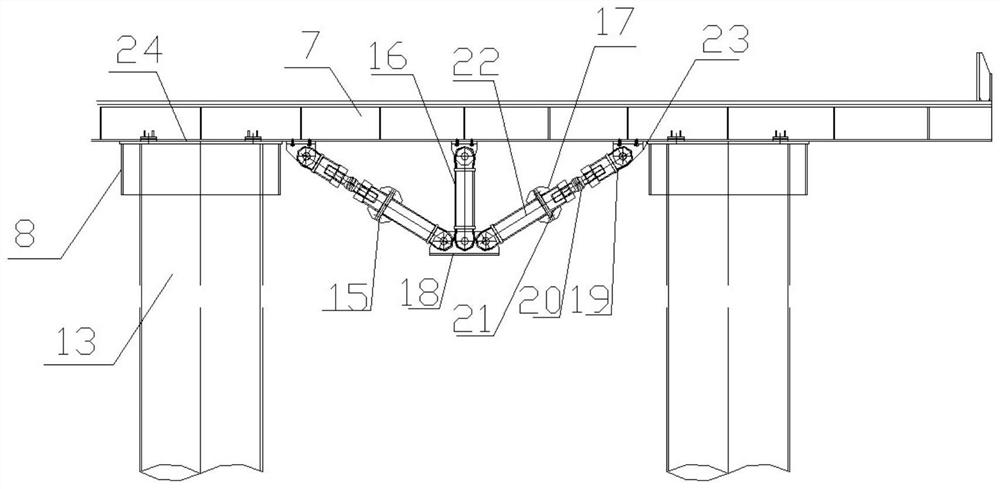

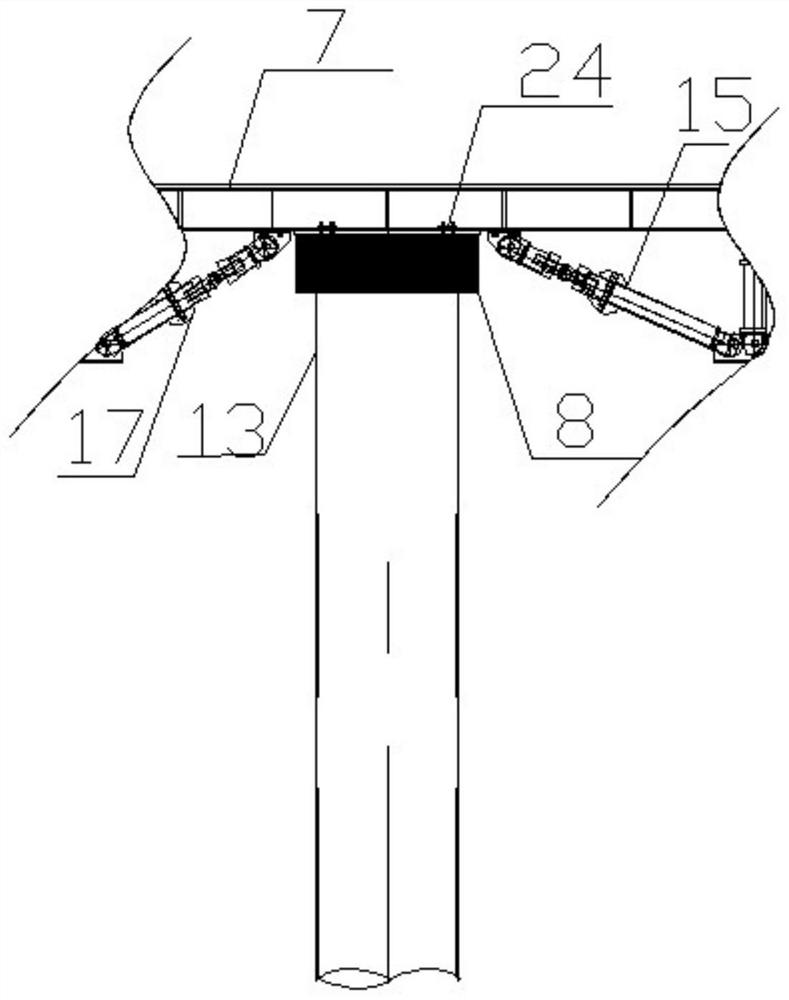

[0043] The front leg of the offshore bridge erecting machine is supported on the top of the front pile, which is the front end support point when erecting the beam. In order to make the front outriggers adapt to the horizontal deviation of the lower steel pipe piles or concrete piles, a transition joint is provided on the front outrigger steel pipe ...

Embodiment 2

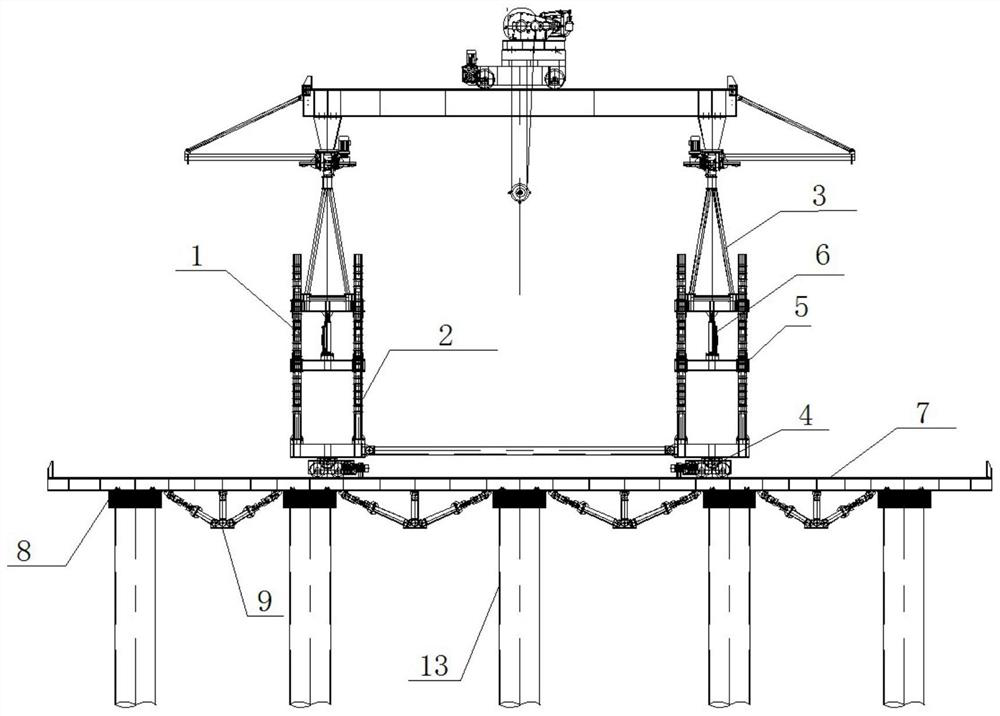

[0057] As a preferred embodiment of the present invention, with reference to the attached Figure 1-7 , this embodiment discloses a bridge-erecting machine at sea, comprising a main girder, a front leg, a middle leg and a rear leg; the front leg of the bridge-erecting machine is connected to the main beam of the bridge-erecting machine The lower chord is locked, and the front outrigger transverse travel mechanism is installed at the lower part of the front outrigger; the upright column of the front outrigger is set as an inner and outer joint structure, and is equipped with a hydraulic jack for adjusting the height of the front outrigger; the front outrigger transverse travel mechanism The bottom of the track beam is connected by bolts to a number of transition sections that are sleeved on the top of the pile, and the distance between the transition sections at the bottom of the track beam of the front outrigger lateral travel mechanism is set according to the distance between ...

Embodiment 3

[0063] As another preferred embodiment of the present invention, refer to the attached Figure 1-7 , this example discloses:

[0064] A construction method of an offshore bridge erecting machine is characterized in that it comprises the following steps:

[0065] Step A, the assembly step of the bridge erecting machine, assemble the bridge erecting machine according to the installation and operation specifications of the bridge erecting machine; when assembling the bridge erecting machine, lock the front leg of the bridge erecting machine with the lower string of the main girder of the bridge erecting machine through the double-ended studs , the front outrigger transverse walking mechanism is installed at the lower part of the front outrigger; the upright of the front outrigger is set as an inner and outer joint structure, and a hydraulic jack is configured to adjust the height of the front outrigger;

[0066] At the bottom of the track beam of the front outrigger transverse r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com