Prefabricated environment-friendly external wall panel

A prefabricated assembly, exterior wall panel technology, applied in the direction of walls, thermal insulation, building thermal insulation materials, etc., can solve the problems of poor waterproof performance and entry into the wall, and achieve the effect of enhancing waterproofness and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

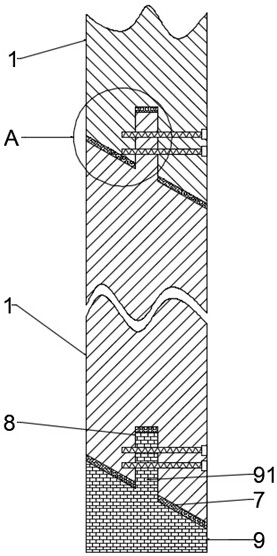

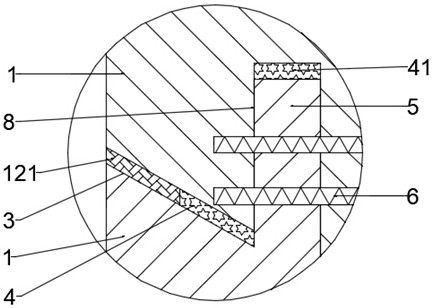

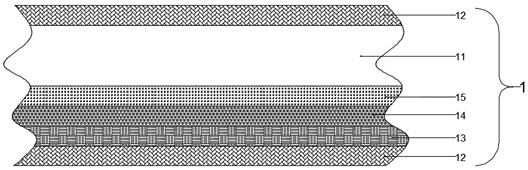

[0024] see Figure 1~3 , in an embodiment of the present invention, a prefabricated and assembled environment-friendly exterior wall panel, including an exterior wall panel 1, the top outer wall and the bottom outer wall of the exterior wall panel 1 are provided with a waterproof mechanism, and the waterproof mechanism includes a The upper slope 3 at the top, the first sealing layer 4, the second sealing layer 41, the second waterproof layer 121, the rectangular bump 5, the lower slope 7 and the rectangular groove 8 at the bottom of the exterior wall panel 1, the rectangular convex The block 5 is set at the center of the upper slope 3, and the rectangular groove 8 is set at the center of the lower slope 7 and inside the exterior wall panel 1. In this embodiment, the upper slope 3 at the top of the exterior wall panel 1 and the exterior wall panel 1 The lower slope 7 of the bottom is matched, the rectangular protrusion 5 is matched with the rectangular groove 8, and the two sid...

Embodiment 2

[0027] see Figure 4 , On the basis of Embodiment 1, a support mechanism is provided on one side of the exterior wall panel 1, and the support mechanism includes a slider 2, a fixed block 10, a support rod 17, a first chute 18, a support block 19, a handle 20. The threaded rod 21 and the second chute 22, the lower surface of the fixed block 10 is fixedly connected with a plurality of rubber suction cups 16, the upper surface of one end of the fixed block 10 is hinged with a support block 19, and the inside of the support block 19 is provided with The first chute 18, the inside of the fixed block 10 is provided with a second chute 22, the second chute 22 is rotatably connected with a threaded rod 21 in the horizontal direction, and the end of the threaded rod 21 away from the support block 19 is penetrated and fixed The block 10 is rotatably connected with it, the threaded rod 21 runs through one end of the fixed block 10 and is fixedly connected with a handle 20, the threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com