Concrete heat-insualting hollow brick making machine and concrete heat-insulaitng brick

A technology of hollow bricks and concrete, which is applied in the direction of manufacturing tools, ceramic molding machines, building materials, etc., can solve the problems of no heat preservation, sound insulation, environmental resource destruction, waste of cultivated land, etc., and achieve energy saving, environmental pollution, and land saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

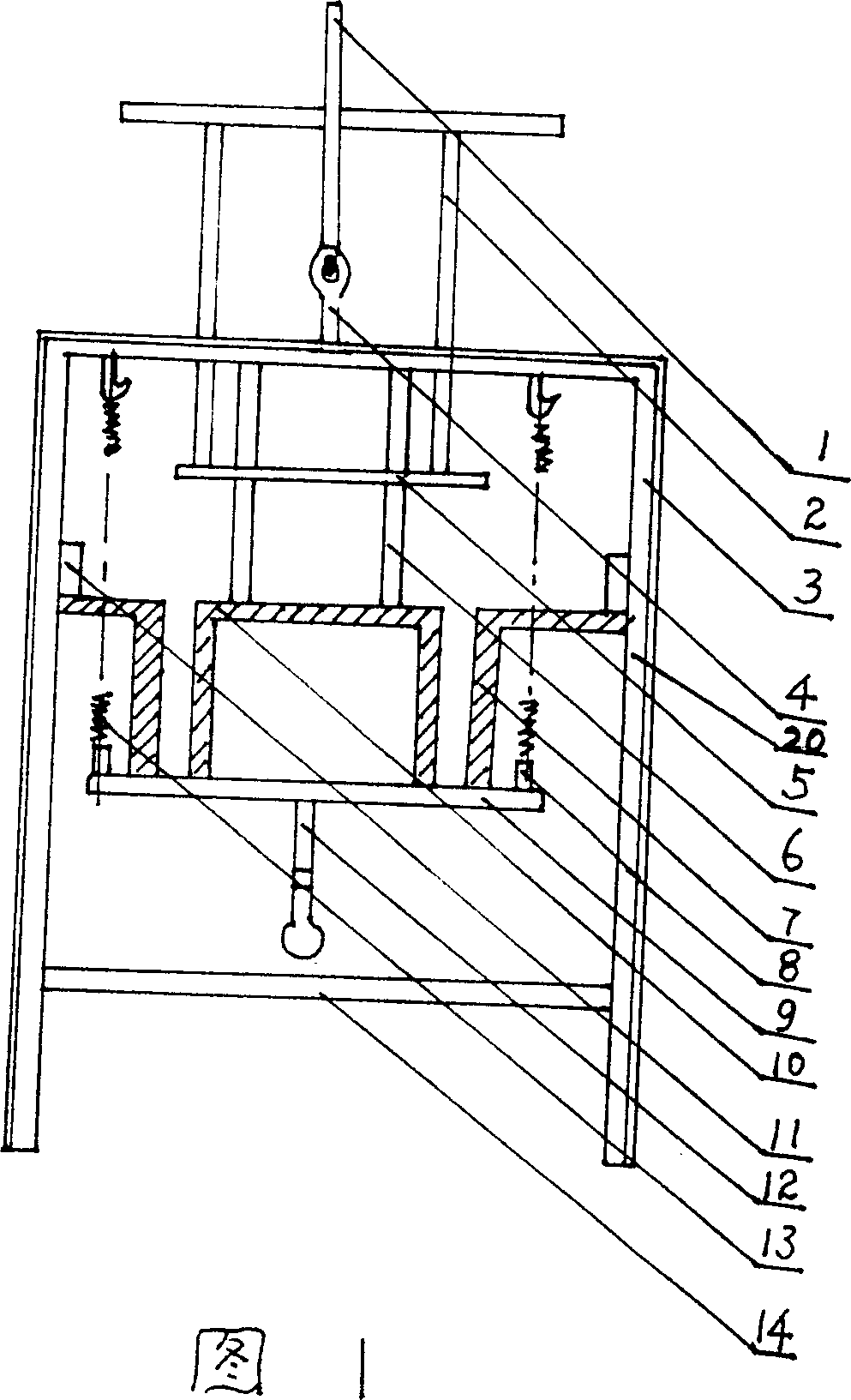

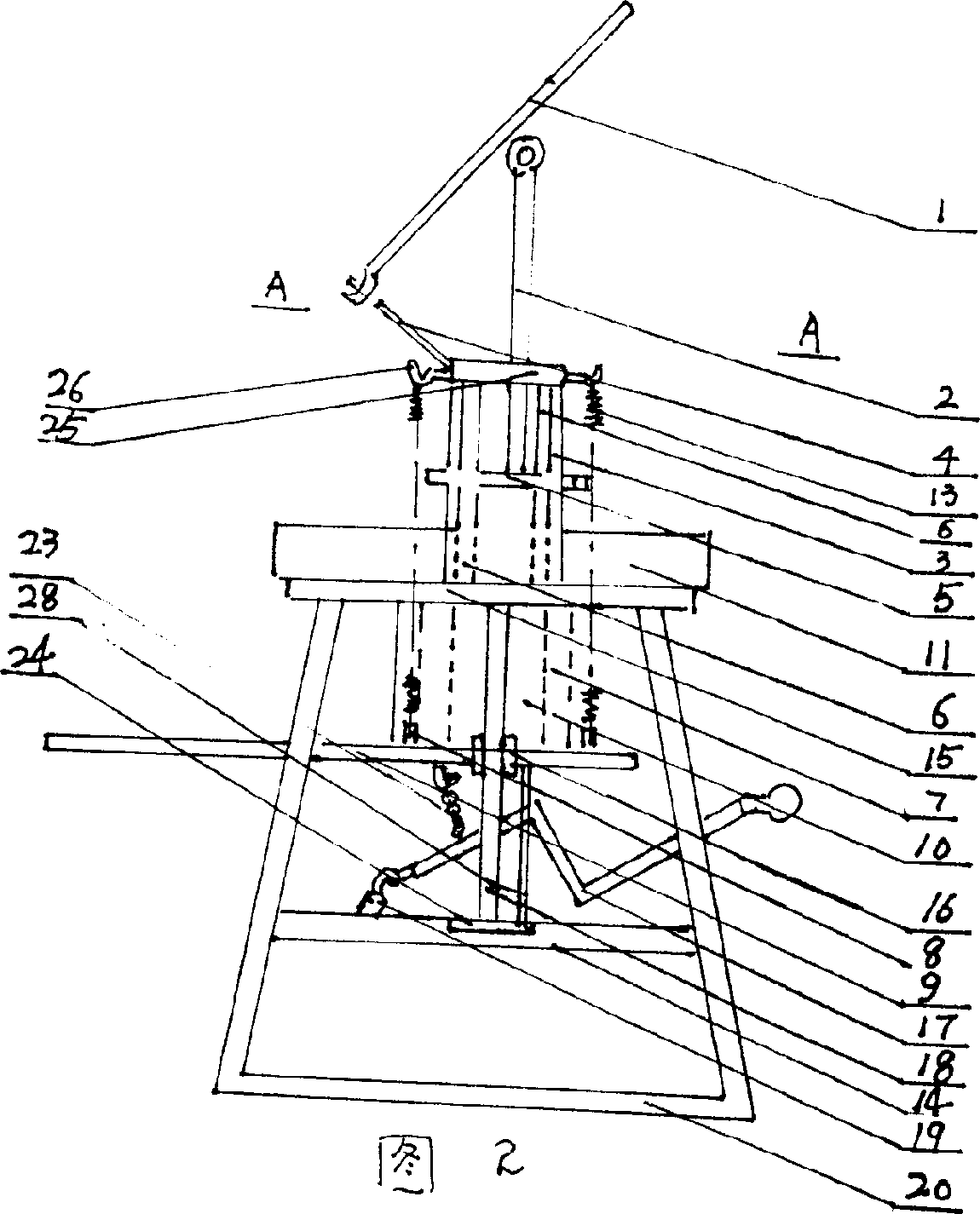

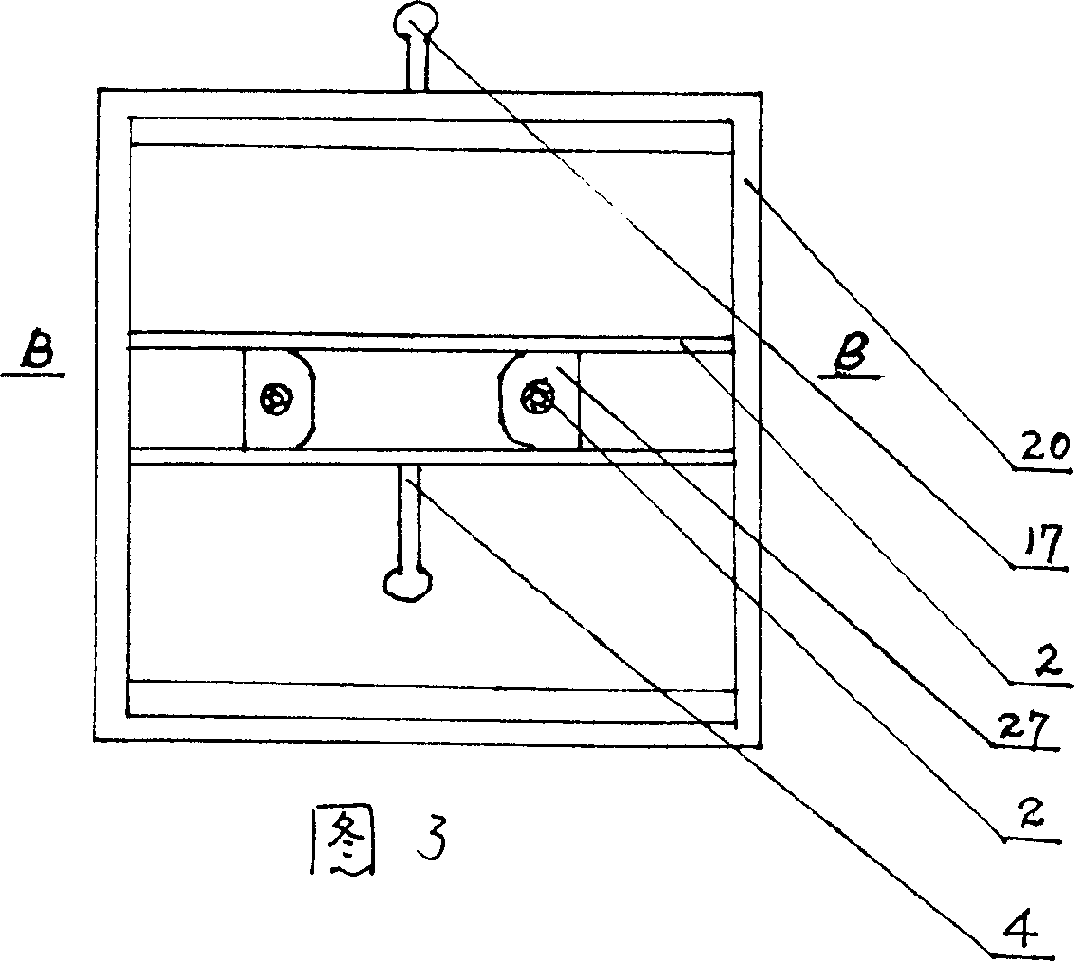

[0012] Concrete thermal insulation hollow brick brick making machine, its main body is a trapezoidal bracket 20 (see Figures 1 and 2), the bracket has three layers of beams, a bracket platform 24 is installed on the inner side of the lower beam 14, and a slide bar 18 is erected on the bracket platform 24, and the slide bar The other end of 18 is fixed with the second floor platform 15, and the support platform 15 inboard end is equipped with axle, is covered with pole sleeve on the axle, and pole sleeve connects pole 23 and supports on the brick formwork supporting plate 9; 15 The crossbeam is a platform structure (see Figure 2), with baffles 11 standing on the left and right sides of the platform, a rectangular brick mold 7 under the platform, and a brick mandrel 10 fixed inside the rectangular brick mold 7, and the brick mandrel 10 is slightly matched with the brick mold. Smaller than the brick mold 7, the lower end of the brick mold 7 is connected with reinforcing ribs aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com