Comprehensive construction method suitable for super-large-section shield tunneling

A super-large cross-section, shield tunneling technology, which is applied in the direction of tunnels, tunnel linings, shaft linings, etc., can solve the problems of difficulty in removing temporary supports in mining methods, segment staggering in empty push section of shield tunneling, large excavation span in mining methods, etc. , to achieve the effect of reducing the risk of segment misalignment, reducing construction difficulty and risk, and reducing the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] A comprehensive construction method suitable for excavation of a super-large section shield tunnel, comprising the following steps:

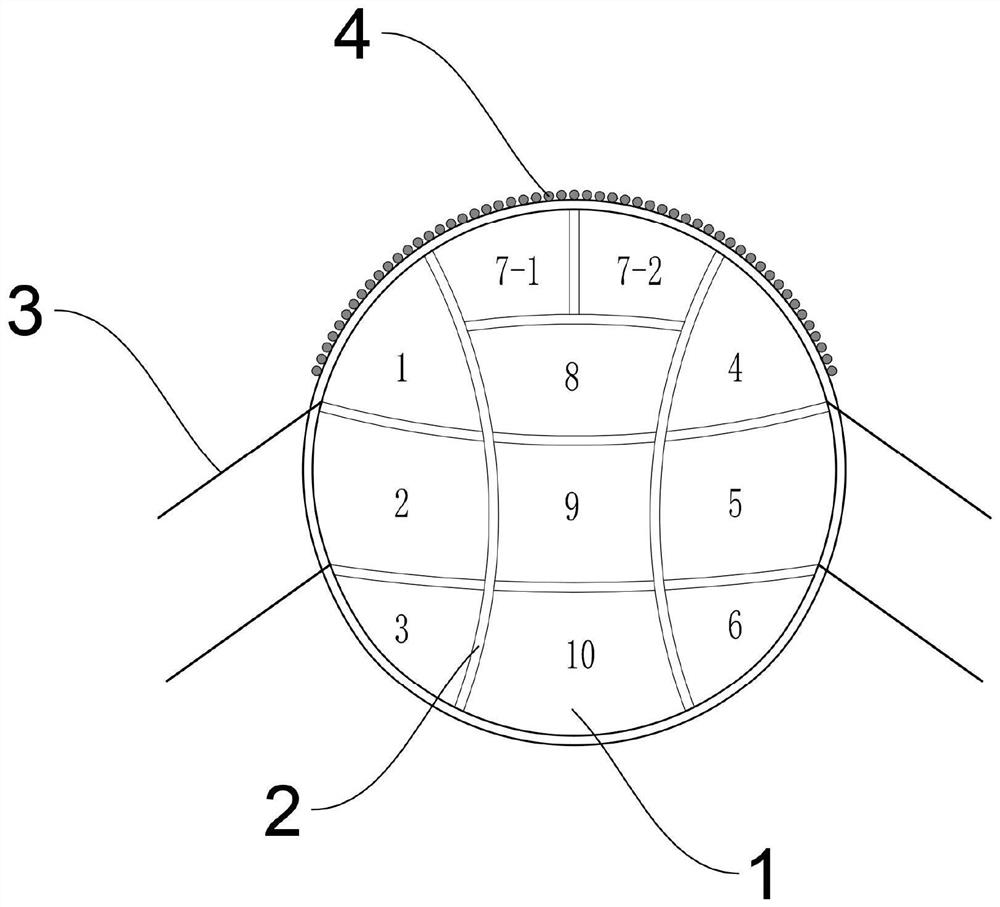

[0024] S1. Using the mining method to form the outer contour section 1 of the tunneling of the shield machine, such as figure 1 As shown, in the mining method construction, advance support 4, system bolt 3, temporary support 2 and shotcrete are required. In order to solve the safety problem between different excavation steps in super-large section mining method construction, the excavation method of double side wall pilot pit and temporary support 2 was chosen, that is, the excavation method of 5 steps and 11 steps.

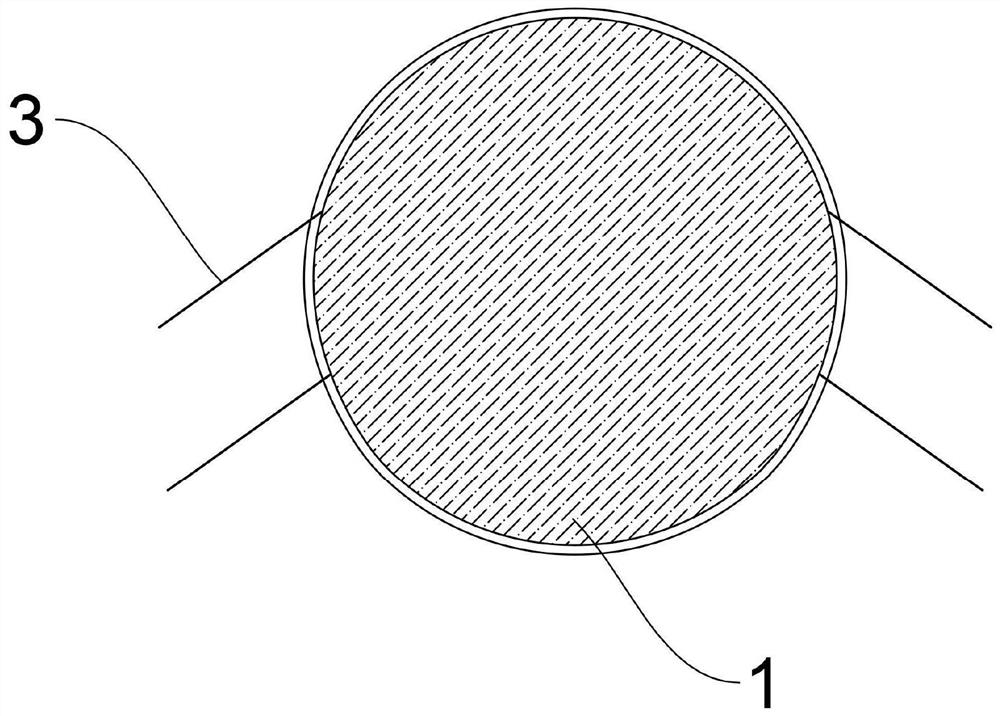

[0025] S2. Before the tunneling of the shield machine, all temporary supports 2 in the section need to be removed. At this time, the secondary lining has not been implemented. In order to solve the requirement that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com