Equipment and method for adjusting continuous concentration of low-concentration tailings and intermittent filling of high-concentration slurry

A high-concentration, low-concentration technology, applied in fillings, mining equipment, earthwork drilling, etc., can solve the problems of increasing the probability of raking and on-site operation, increasing the cost of materials and processing costs, and increasing the cost of purchasing key components. To achieve the effect of reasonable equipment selection and quantity, increase of effective utilization coefficient, and reduction of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

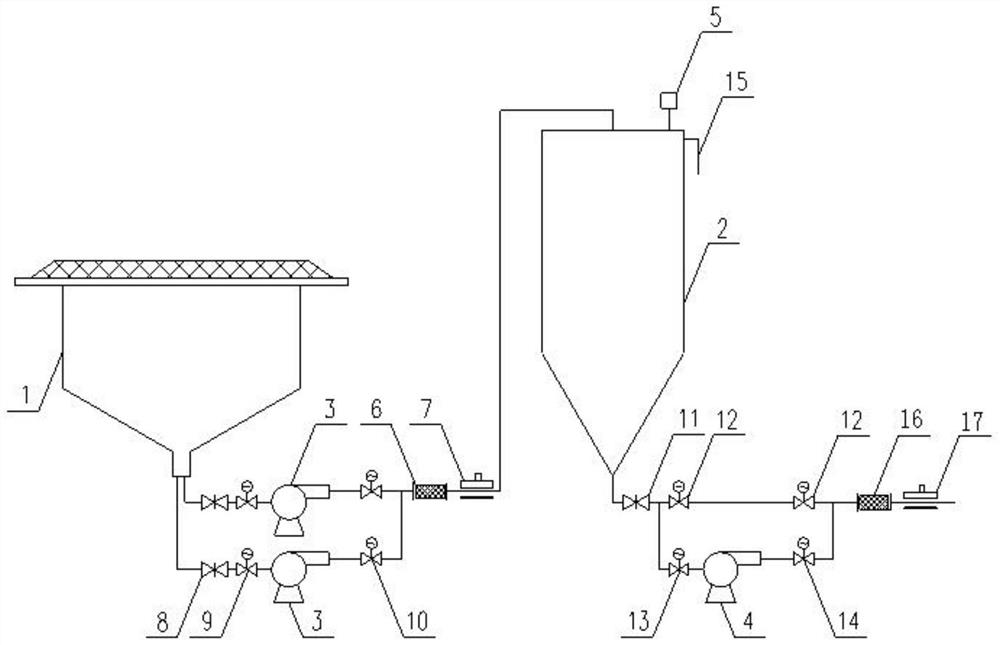

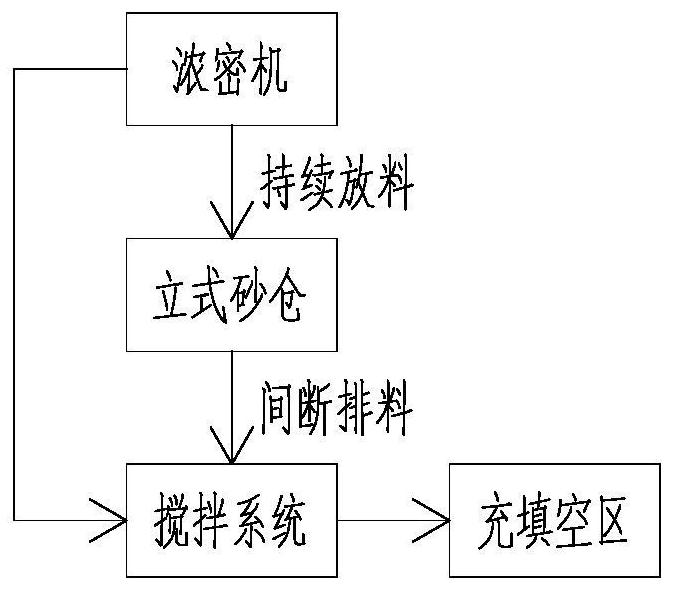

[0057] A device for adjusting the continuous concentration of low-concentration tailings and intermittent filling of high-concentration slurry, including: a thickener 1 and a vertical sand bin 2;

[0058] Wherein, the bottom of the thickener 1 is connected to the top of the vertical sand bin 2, and the bottom of the vertical sand bin 2 is provided with a discharge port for transporting the tailings to the stirring device;

[0059] Thickener underflow thickener pump 3 is installed between thickener 1 and vertical sand bin 2;

[0060] The top of the vertical sand bin 2 is provided with a sand bin level gauge 5, and the side wall of the vertical sand bin 2 is provided with a sand bin overflow pipe 15;

[0061] A sand bin underflow thick slurry pump 4 is arranged between the outlet of the vertical sand bin 2 and the stirring device.

[0062] In one embodiment, there are several underflow thickener pumps 3 of the thickener, and several underflow thickener pumps 3 of the thickener ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com