Crankshaft oil seal assembly, crankcase and vehicle

A crankcase and oil seal technology, applied in the field of vehicles, can solve the problems of seal failure, affecting the efficiency of oil seal press-fitting, factory production rhythm, and increasing manufacturing costs, and achieve the effect of avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

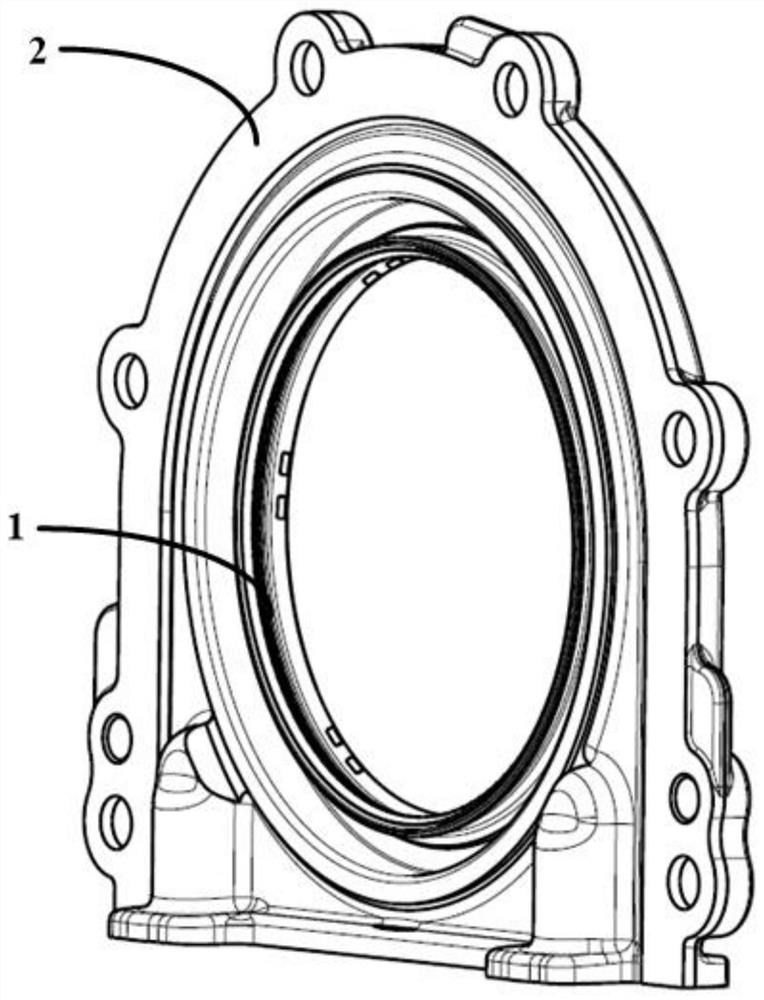

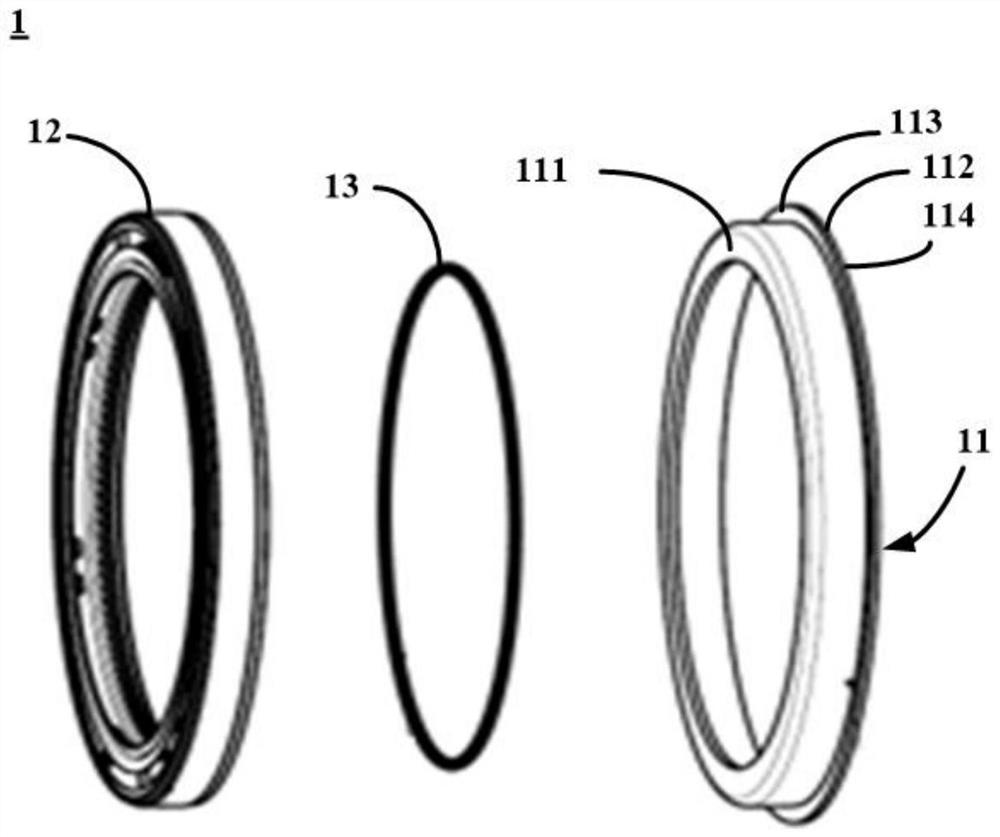

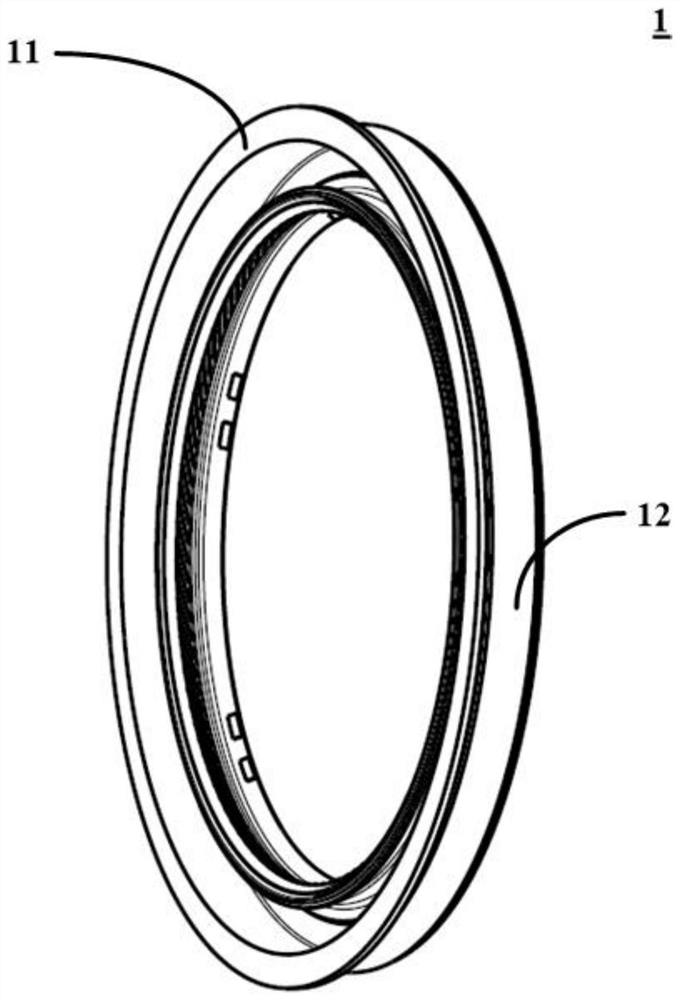

[0031] figure 1 A schematic perspective view of a crankshaft oil seal assembly according to an embodiment of the present invention is shown. The crankshaft oil seal assembly is assembled on the crankshaft of the crankcase. Such as figure 1 As shown, the crankshaft oil seal assembly includes an oil seal seat 2 and an oil seal 1 assembled on the oil seal seat 2 . figure 2 A schematic exploded view of an oil seal 1 according to an embodiment of the invention is shown. image 3 A schematic structural diagram of an oil seal 1 according to an embodiment of the present invention is shown. Such as figure 2 and image 3 As shown, the oil seal 1 includes a frame 11 and an annular sealing body 12 sleeved on the outside of the frame 11 . Wherein, the material of the skeleton 11 can be, for example, a metal material. The annular sealing body 12 is made of soft material, such as rubber. The skeleton 11 is composed of an annular skeleton body 111 and an annular boss 112 extending r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com