The processing device and processing technology of the arc shape of the inner hole of the watch jewel bearing

A gemstone bearing and processing device technology, applied in clocks, clocks, repair tools, etc., can solve problems such as discrepancies, positional deviations of drill holes, affecting processing efficiency and yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

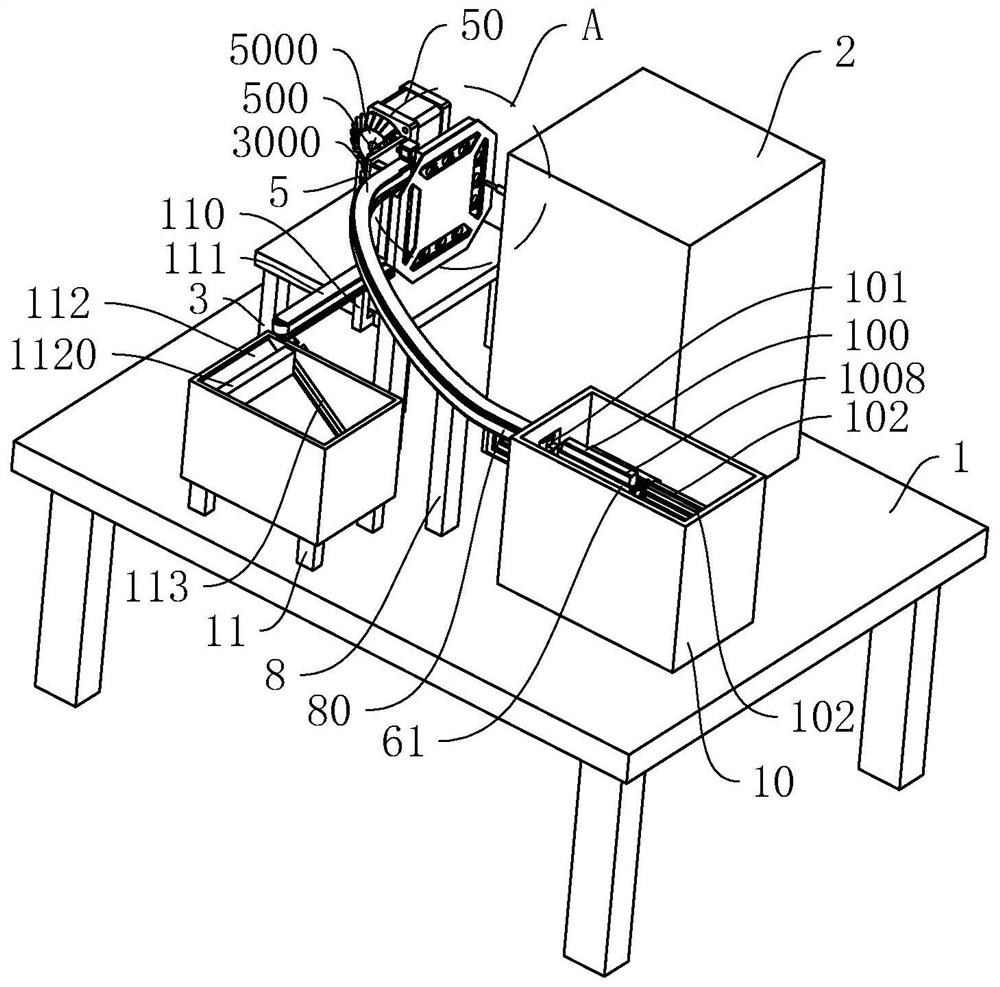

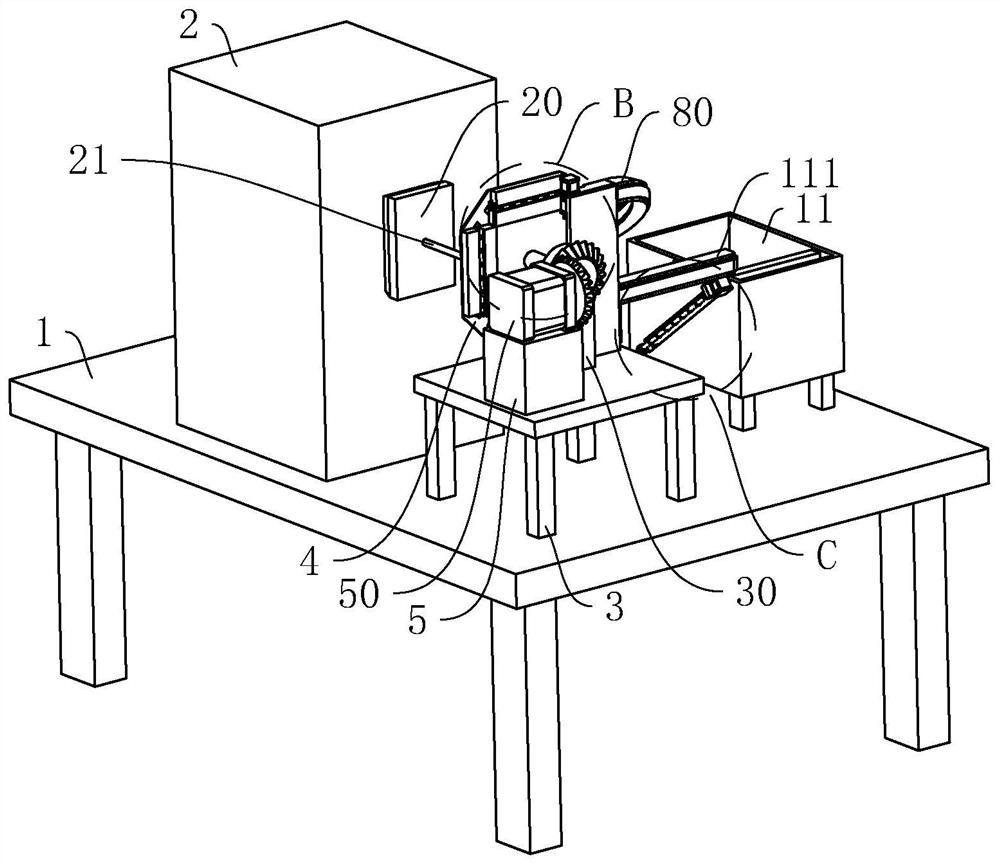

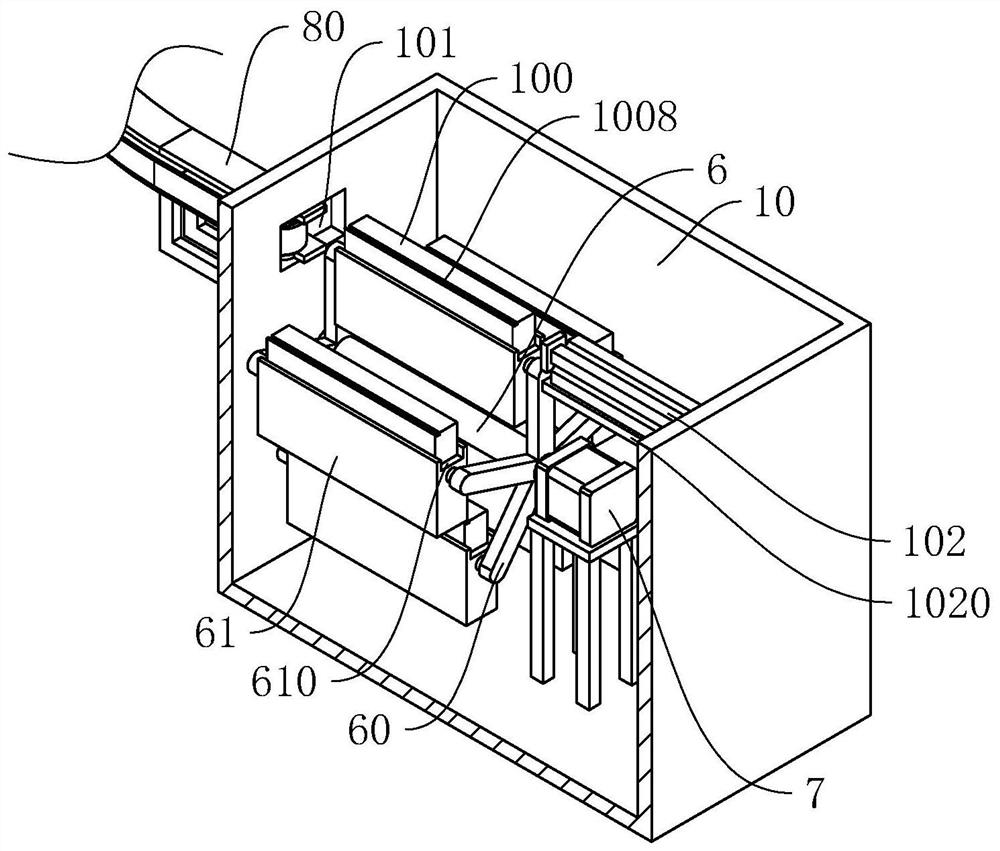

[0047] The following is attached Figure 1-9 The application is described in further detail.

[0048] The embodiment of the present application discloses a processing device for arc-shaped inner holes of watch jewel bearings. refer to figure 1 and figure 2 , the processing device comprises a workbench 1, on which a micro-drilling machine body 2 is fixed, wherein a micro-drill base 20 is installed on one side of the micro-drilling machine body 2, and the micro-drill base 20 is away from the micro-drill One side of the hole machine body 2 is equipped with a micro-drill removal shaft 21, and meanwhile, a drill bit 210 is installed on the micro-drill removal shaft 21.

[0049] In addition, a bearing fixing mechanism is installed on the workbench 1 , and the bearing fixing mechanism is located at the side of the drill bit 210 of the micro-drilling machine body 2 as a whole. When the gemstone to be processed needs to be drilled, the operator needs to fix the gemstone to be proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com