Rolling bearing residual life prediction method considering model and data uncertainty

A rolling bearing, uncertainty technology, applied in the field of remaining life prediction of mechanical equipment, can solve problems such as monotonicity of health factors, unfavorable maintenance plans, and insufficient trend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

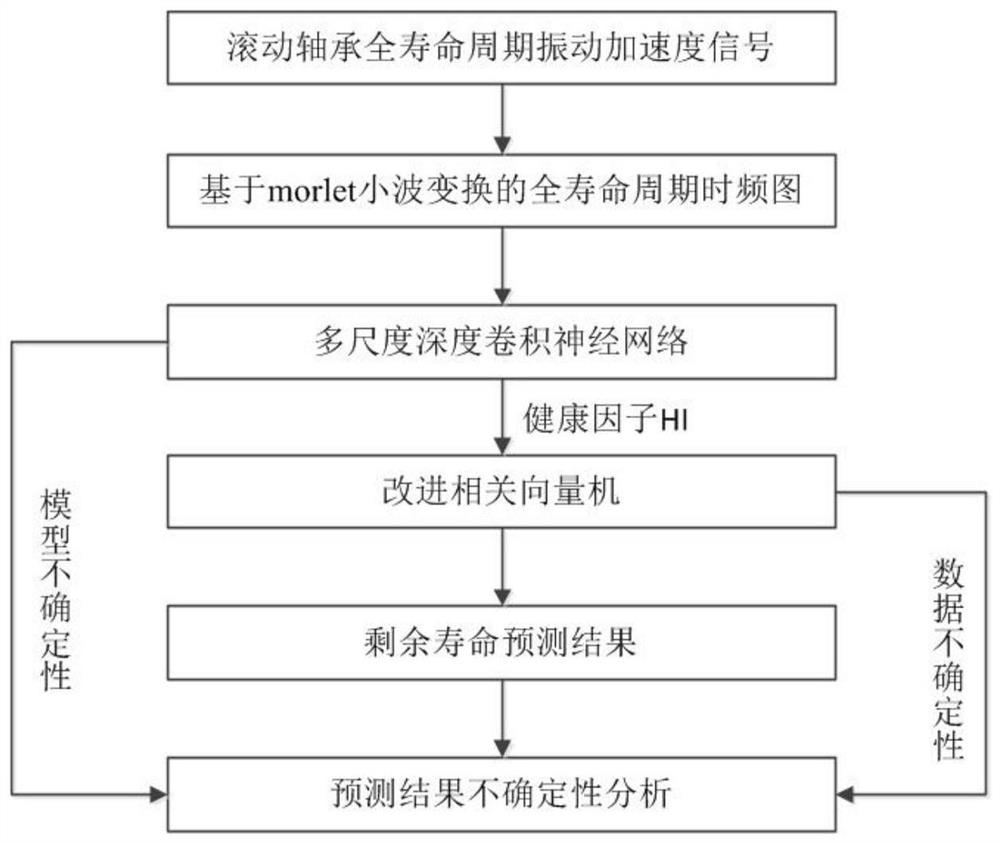

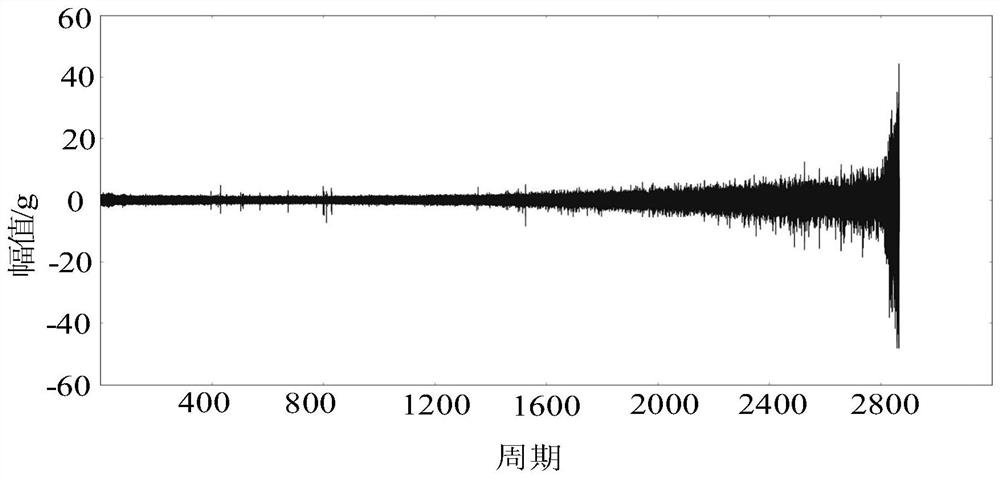

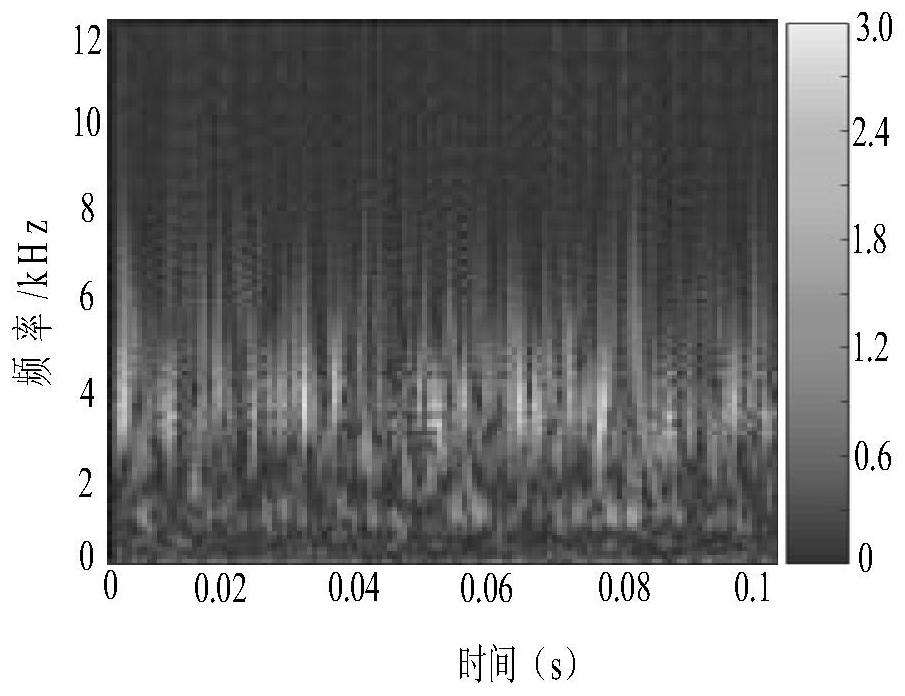

[0045] The method for predicting the remaining life of rolling bearings considering model and data uncertainty shown in this embodiment, as shown in the attached figure 1 As shown, the method mainly includes the following four parts: one is to use morlet wavelet transform to convert the vibration acceleration signal into a time-frequency map; the other is to build a multi-scale deep convolutional neural network to construct a health factor, and use the ten-fold cross-validation method to quantitatively analyze the model The third is to use the improved correlation vector machine fused with the polynomial regression model to predict the remaining life according to the health factor data, and quantitatively analyze the data uncertainty; the fourth is to comprehensively consider the model uncertainty and data uncertainty to obtain the uncertainty of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com