Porous metal current collector, preparation method, negative electrode and battery

A porous metal and current collector technology, applied in the direction of electrode carrier/current collector, electrode manufacturing, battery electrodes, etc., can solve the problems of complex preparation process of metal current collectors, achieve formation and growth inhibition, deep discharge, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

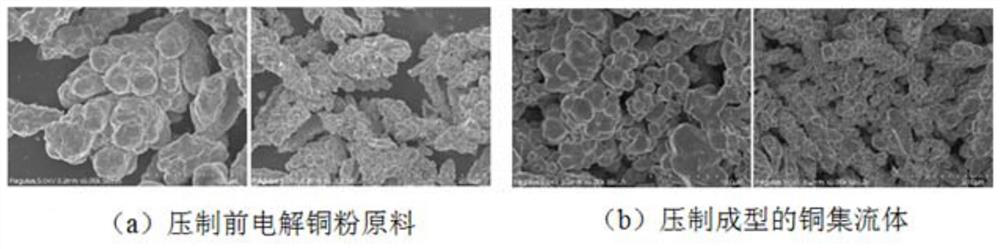

[0047] The preparation method of the porous metal current collector of the present invention comprises the steps of pre-mixing dendritic metal particle powder and an organic binder and then compacting; the metal particle powder contains electrolytic metal particle powder prepared by an electrolytic method, and the The electrolytic metal particle powder has the following characteristics: it has a dendritic structure, the particle size distribution is between 0.1-100 microns, and the tap density is 2.0-3.5g / cm 3 , the purity is greater than 90%.

[0048] After a large number of tests and analyzes by the inventor, the copper current collector with high specific surface area of the present invention has strong lithium affinity due to the capillary siphon force, so that molten metal lithium can easily immerse into the current collector, and quickly and evenly dispersed, so as to prepare a three-dimensional structure of high specific surface area lithium metal negative electrode, ...

Embodiment 1

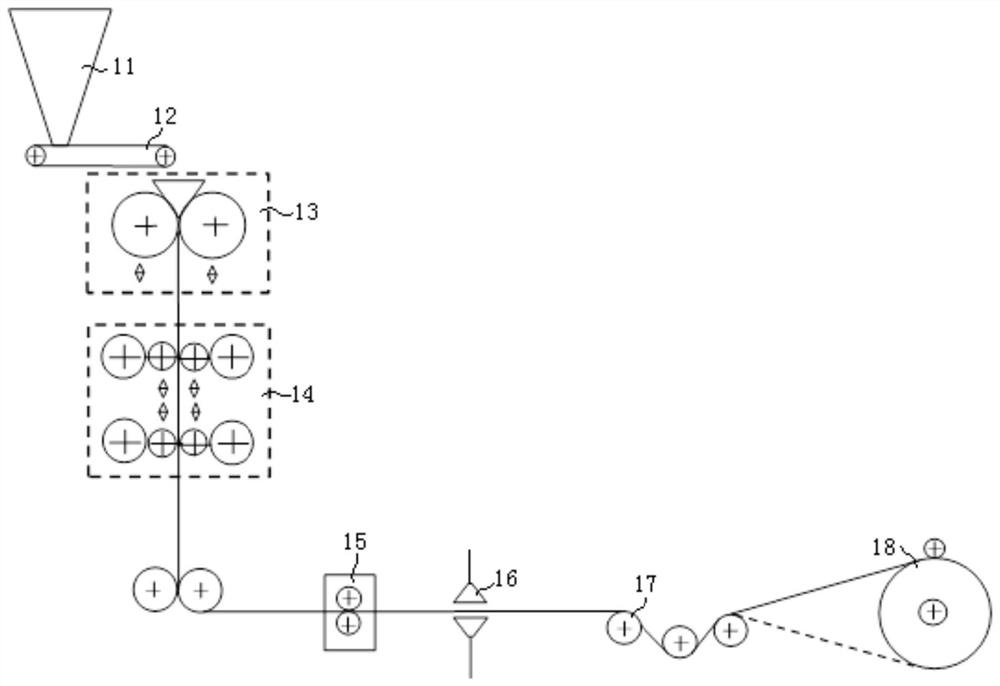

[0064] A preparation process of the porous metal current collector provided in this embodiment is to carry out roll-to-roll (Roll-to-Roll) rolling continuous pressing by powder rolling method, such as figure 1 shown. Preferably, a raw material particle is an electrolytic copper powder having the following characteristics: 1) has a microscopic dendritic structure and a nanoscale irregular surface microstructure; 2) the particle size distribution is between 0.1-100 microns; 3) the tap density At 2.0-3.5g / cm 3 4) the purity is more than 95%.

[0065] A typical continuous rolling process is as follows:

[0066] 1) Fully mix the above electrolytic copper powder and anionic polyacrylamide (APAM) according to the weight ratio of 9:1;

[0067] 2) Put the above mixture into figure 1 In the mixing device shown, the mixture particles are evenly conveyed to the gap between the pressure rollers through the quantitative supply device;

[0068] 3) Roll the mixture particles into a porou...

Embodiment 2

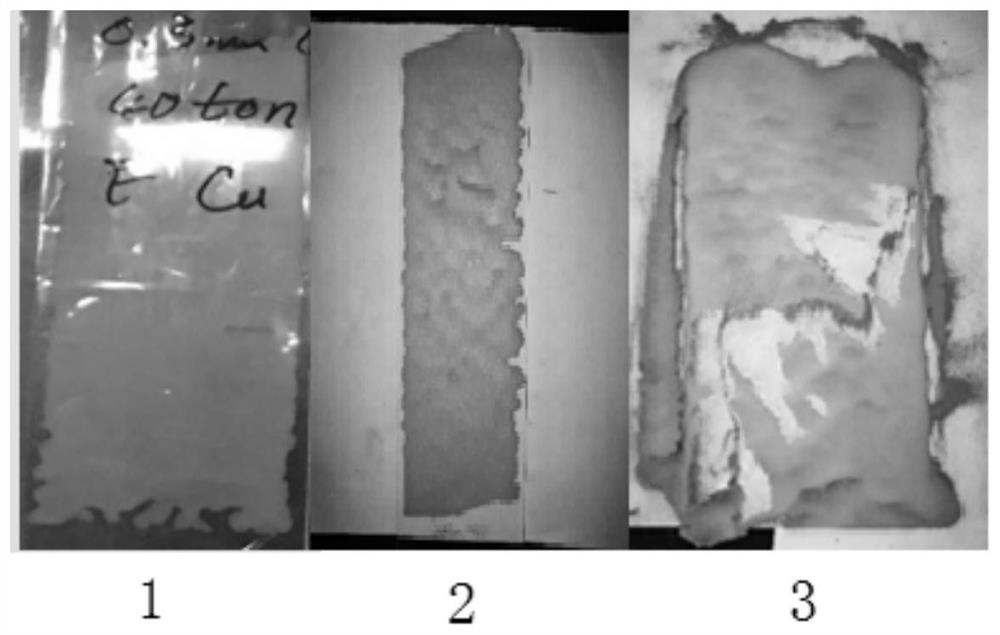

[0076] Another preparation method of the porous metal current collector provided in this example is to use the tableting method to compress the powder material that is fully mixed with the metal particle powder and the organic binder. The electrolytic copper powder of embodiment 1 is also selected as the raw material particles, and the specific technological process is as follows:

[0077] 1) Fully mix the electrolytic copper powder and anionic polyacrylamide (APAM) according to the weight ratio of 100:1;

[0078] 2) The above mixture is put into the mixing device, and put into the die cavity of the tablet press through the quantitative supply device, and the raw material particles are evenly distributed in the die cavity through the distributing device;

[0079] 3) After setting the appropriate pressure and holding time, the pressure is between 10 tons and 50 tons, start the tablet press, use high-frequency heating, the temperature is between 200 ° C, and press the metal part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Void diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com