Non-contact intelligent card winding butt-welding production process and system

A non-contact, production system technology, applied in connection, coil manufacturing, circuit/collector components, etc., can solve problems such as easy offset, affect the quality of chip welding, and virtual welding of wire ends and chips, and improve production. quality, improve the quality of chip welding, and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

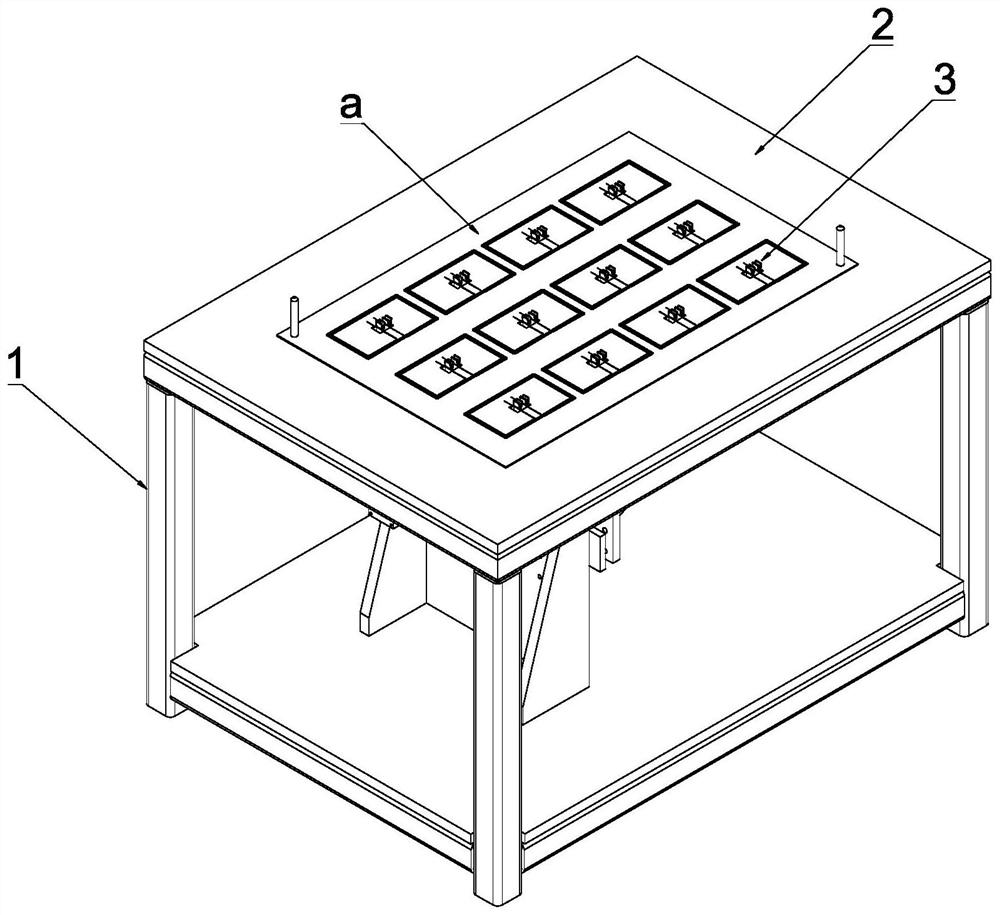

[0050] see Figure 13 , this embodiment discloses a non-contact smart card winding butt welding production system, including a punching module for punching sheet a, a coil winding module for winding a coil on sheet a, Tape sticking module for sticking tape 8 for fixing chip 9 on sheet a, positioning and snapping module for positioning coil wire ends, chip sticking for sticking chip 9 on the hole of sheet a module and a chip welding module for welding the chip 9 and the coil wire head.

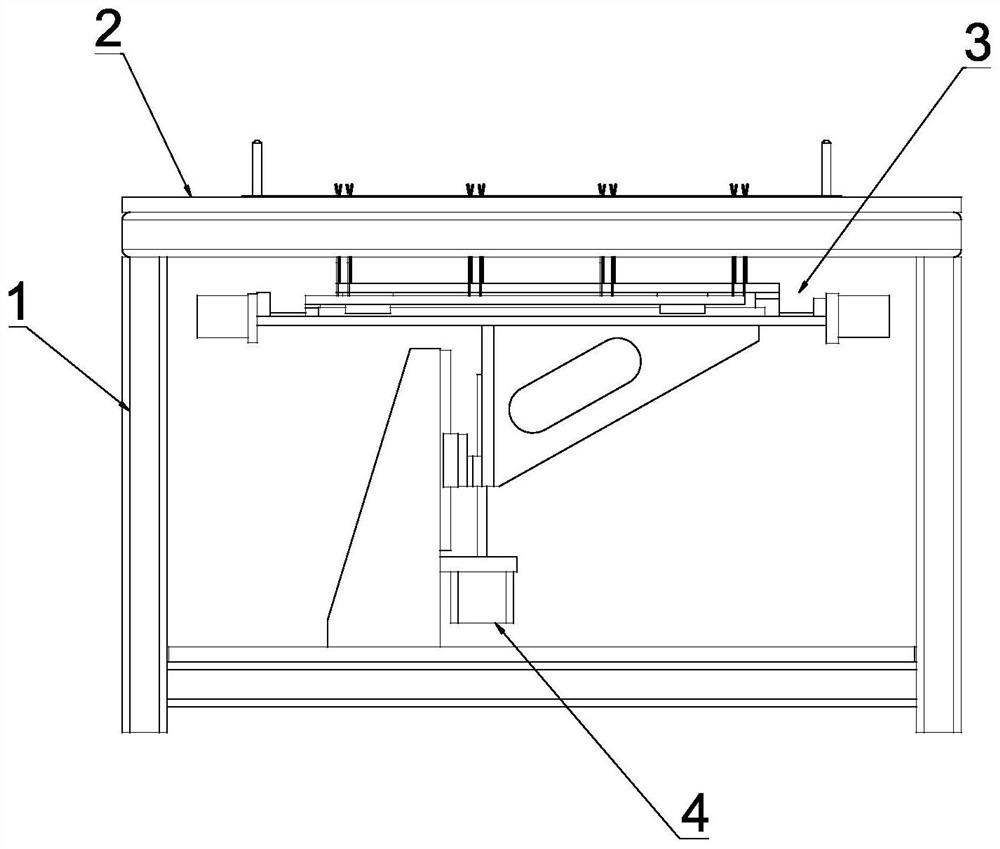

[0051] see Figure 1-Figure 2 , the positioning and clapping module includes a mounting frame 1, a sheet material placement platform 2 arranged on the mounting frame 1 for placing the sheet material a, and a sheet material placing platform 2 arranged on the mounting frame 1 for placing the coil thread ends on the sheet material a A straightening mechanism 3 for shooting straight and a vertical driving mechanism 4 for driving the straightening mechanism 3 to move vertically.

[0052] see Figu...

Embodiment 2

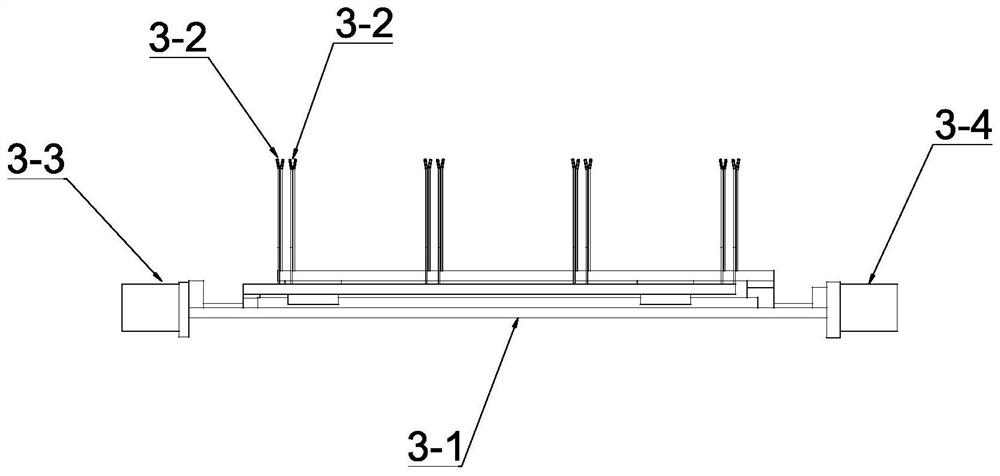

[0080] see Figure 14 , the other structures in this embodiment are the same as those in Embodiment 1, the difference is that the positive driving mechanism of the camera includes a driving motor 3-5, a gear 3-6 connected to the main shaft of the driving motor 3-5, and the The first rack 3-7 meshing below the gear 3-6 and the second rack 3-8 meshing above the gear 3-6, the first rack 3-7 is aligned with the first rack The plate 3-21 is fixedly connected, and the second rack 3-8 is connected to the second positive plate 3-22. Through the above-mentioned setting, it is also possible to realize the positive movement of the first positive plate 3-21 and the second positive plate 3-22.

Embodiment 3

[0082] Other structures in this embodiment are the same as those in Embodiment 1, the difference is that: the first positive drive mechanism 3-3, the second positive drive mechanism 3-4 and the vertical drive mechanism 4 can all use motors and The way of belt drive combination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com