Backing member for friction stir spot welding device, friction stir spot welding device, friction stir spot welding method, and joint structure

A technology of friction stir and point joining, which is applied in the direction of auxiliary equipment, welding equipment, manufacturing tools, etc., can solve the problems of reduced tool life, significant tool friction, and large-scale joint time of the device, so as to prevent the reduction of tool life and improve The effect of joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments will be described below with reference to the drawings.

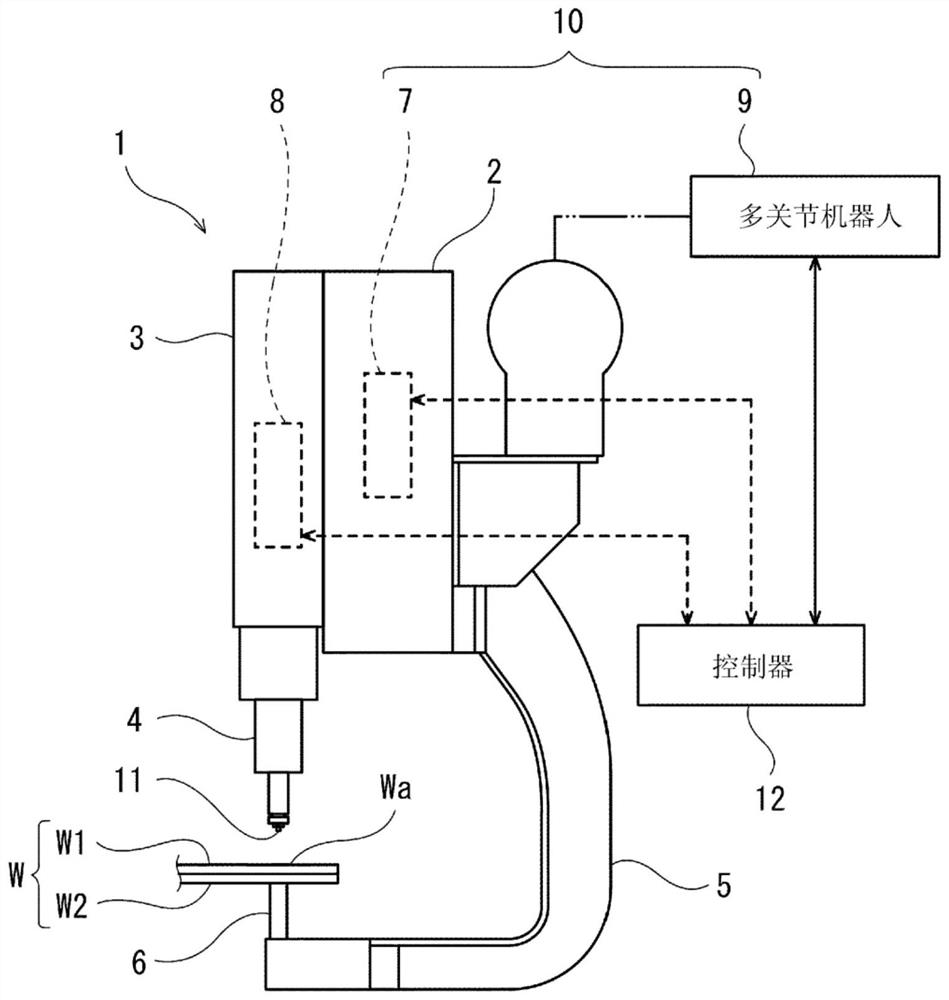

[0026] figure 1 It is a configuration diagram of the friction stir point welding device 1 according to the embodiment. Such as figure 1 As shown, the workpiece W is a pair of plate materials W1 and W2 overlapping each other, and is made of steel, for example. The friction stir spot welding apparatus 1 performs spot welding on an overlapping portion Wa of a pair of plate materials W1, W2. The friction stir spot welding apparatus 1 includes a base body 2 , a movable body 3 attached to the base body 2 , and a tool holder 4 protruding from the movable body 3 toward the workpiece W. As shown in FIG. The movable body 3 is attached to the base body 2 so as to be slidable and displaceable along the axis of the tool holding body 4 . The tool holder 4 is configured to be rotatable about its axis, and a tool 11 is detachably attached to a distal end portion of the tool holder 4 .

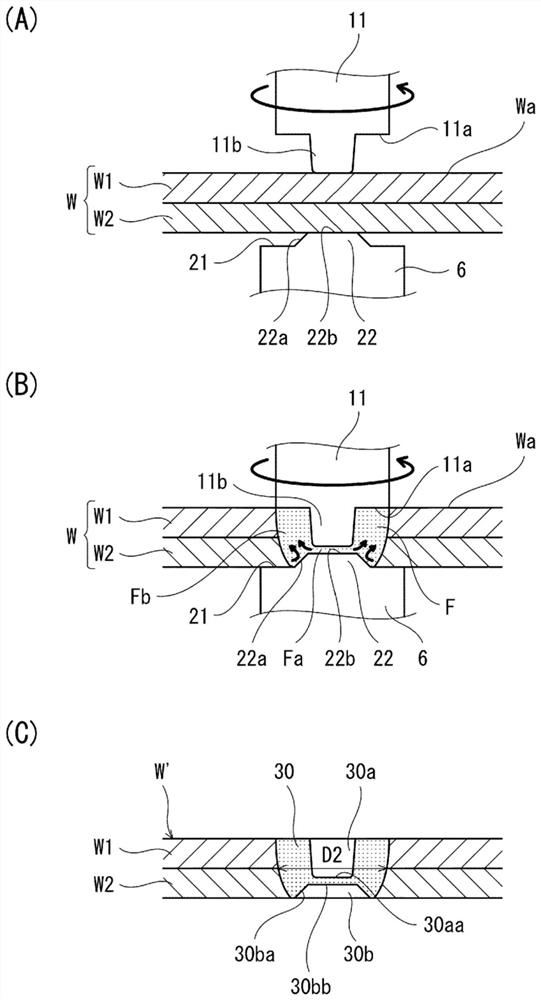

[0027] The tool 11 has: a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap