Efficient impurity removing device for carding machine

A carding machine, high-efficiency technology, applied in the direction of deburring device, cleaning with suction device, textile and paper making, etc. Cleaning effect, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-7 The application is described in further detail.

[0038] The embodiment of the present application discloses a high-efficiency impurity removal device for a carding machine.

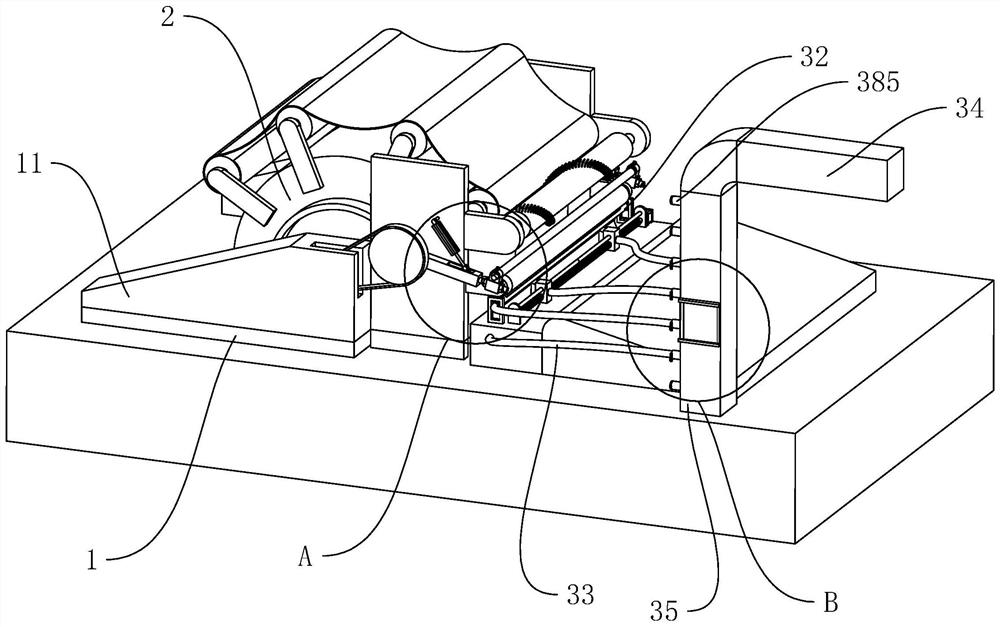

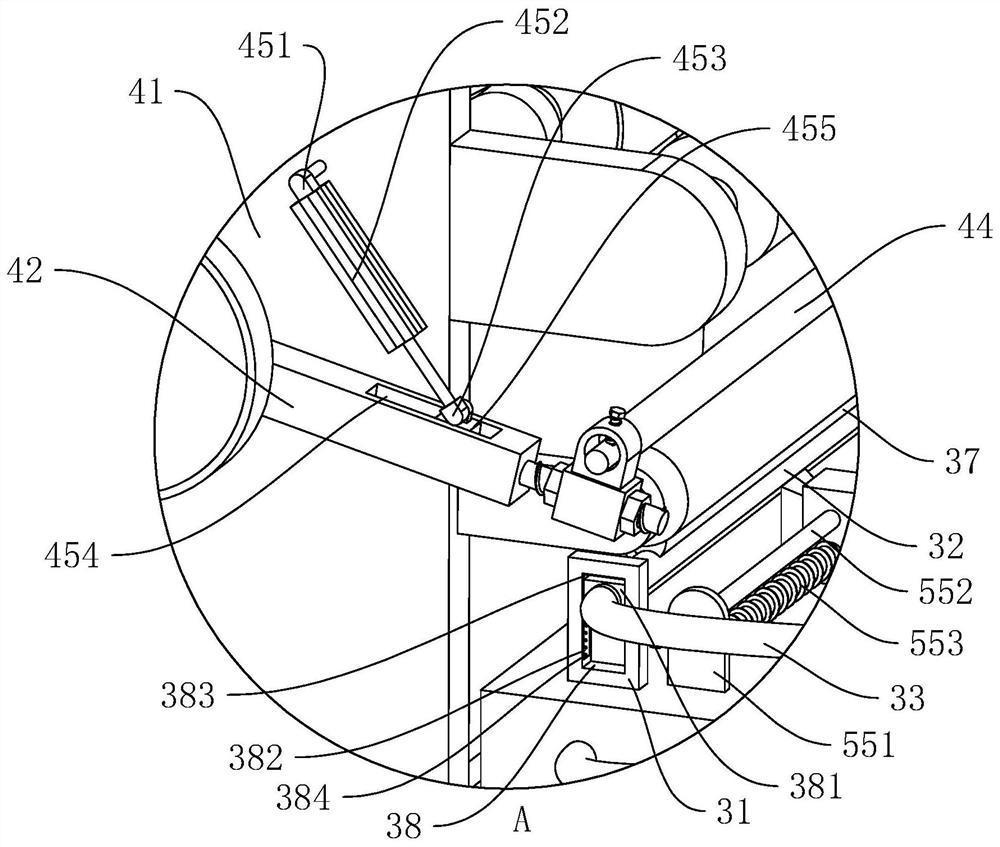

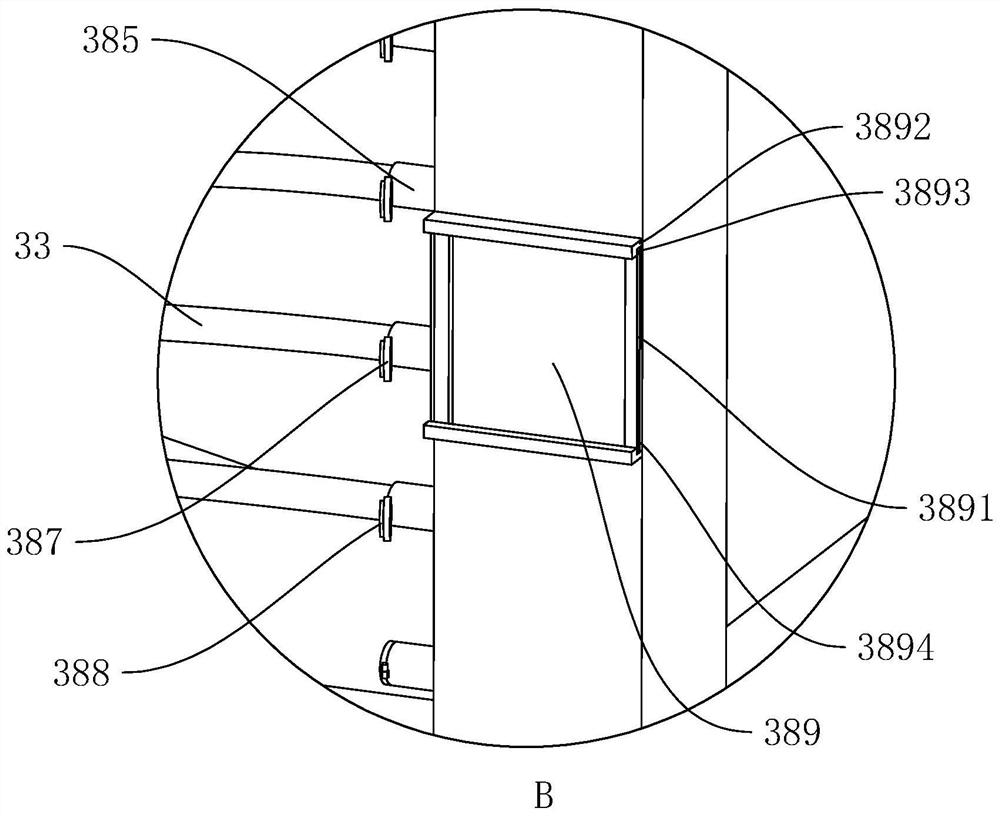

[0039] refer to figure 1 , Figure 4 , a high-efficiency impurity removal device for a carding machine, including a frame 1 arranged in a working environment, on which a frame 11 is provided through bolted connections, wherein, on the top surface of the frame 11, a Carding machine body 2, the input end and output end of carding machine body 2 are arranged on the same side, the input end of carding machine body 2 is located at the upper part of its output end, after the cotton web is input from the input end, it passes through the inside of carding machine body 2 After the structure is opened and loosened, it is output from the output end. In addition, a cleaning device capable of removing impurities from the cotton web is provided at the working portion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com