Condiment raw material drying device with good drying effect

A drying device and seasoning technology, applied in drying, drying machine, drying solid materials and other directions, can solve the problem of poor drying effect, slow drying speed, and small contact time and area between seasoning raw materials and hot air And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

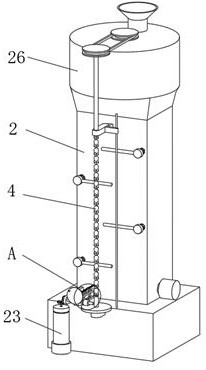

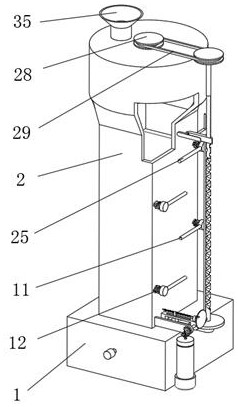

[0040] Example: Reference Figure 1-8 The seasoning raw material drying device with good drying effect shown includes a base 1 . The base 1 may be any base structure in the prior art, such as a metal base.

[0041] A drying box 2 is fixedly installed on the top side of the base 1, and the drying box 2 may be any metal box in the prior art, which is welded to the top side of the base 1 for regulation.

[0042] The top side of drying casing 2 is fixedly installed with transition box, and the top side of transition box is fixedly installed with breaking up box 26, and breaking up box 26 can be any metal box in the prior art, and transition box and Breaking up box 26 and drying box body 2 are all connected.

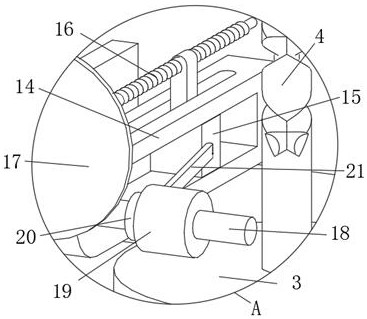

[0043] A side inner wall of the drying box 2 is rotatably equipped with a plurality of rotating shafts 9, the rotating shaft 9 can be any metal shaft in the prior art, and one side of the plurality of rotating shafts 9 is fixedly equipped with a mesh plate 10, the mesh plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com