Quality inspection sampling device for chemical reagent production

A technology for chemical reagents and sampling devices, applied in the field of quality inspection sampling equipment, can solve the problems of reduced work efficiency, no production equipment, and high failure rate, and achieve the effects of reducing labor intensity, improving work efficiency, and improving sampling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

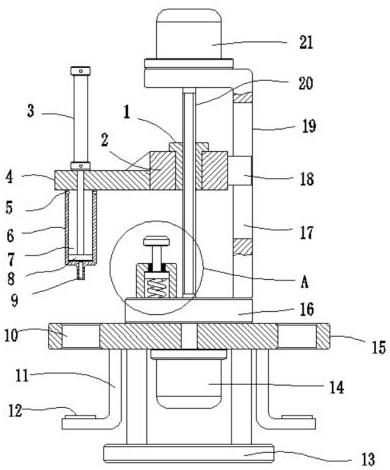

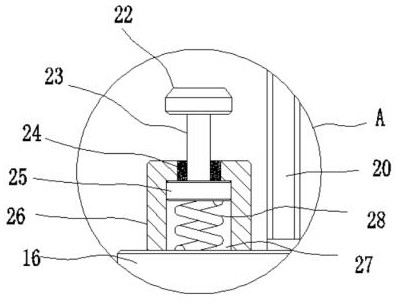

[0022] like Figure 1-2 As shown, a kind of quality inspection sampling device for chemical reagent production includes a base 13, and a plurality of columns are installed above the base 13 to be horizontally provided with a mounting base 15 with a circular cross section, and on the mounting base 15 There are a plurality of clamping grooves 10 in the form of through holes for clamping and storing test tubes for storing chemical reagents in an array along its axial direction. The bottom of the mounting base 15 is provided with multiple L-shaped brackets 11. The horizontal section of the bracket 11 corresponds to a plurality of clamping grooves 10 respectively, and it is used to support the test tubes for storing chemical reagents. The motor 14 is driven to be connected with a rotating base 16, the rotating base 16 is coaxial with the mounting base 15, and a bearing base 19 is vertically installed on it, and a sliding block 2 is vertically slidably connected on the bearing base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com