Gel temperature testing method for polyvinyl chloride paste resin

A polyvinyl chloride paste and gel temperature technology, which is applied in the preparation of test samples, measuring devices, sampling, etc., to achieve the effect of eliminating the influence of human factors, reliable results and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of gel temperature test method for polyvinyl chloride paste resin, comprises the steps:

[0034] S100, testing the viscosity of the polyvinyl chloride paste resin under heating at a fixed heating rate, and obtaining a corresponding viscosity-temperature curve;

[0035] S200. Determine the tangent of two sharply changing curve segments on the viscosity-temperature curve;

[0036] S300. Determine the temperature corresponding to the intersection point of the two tangent lines as the gel temperature of the polyvinyl chloride paste resin;

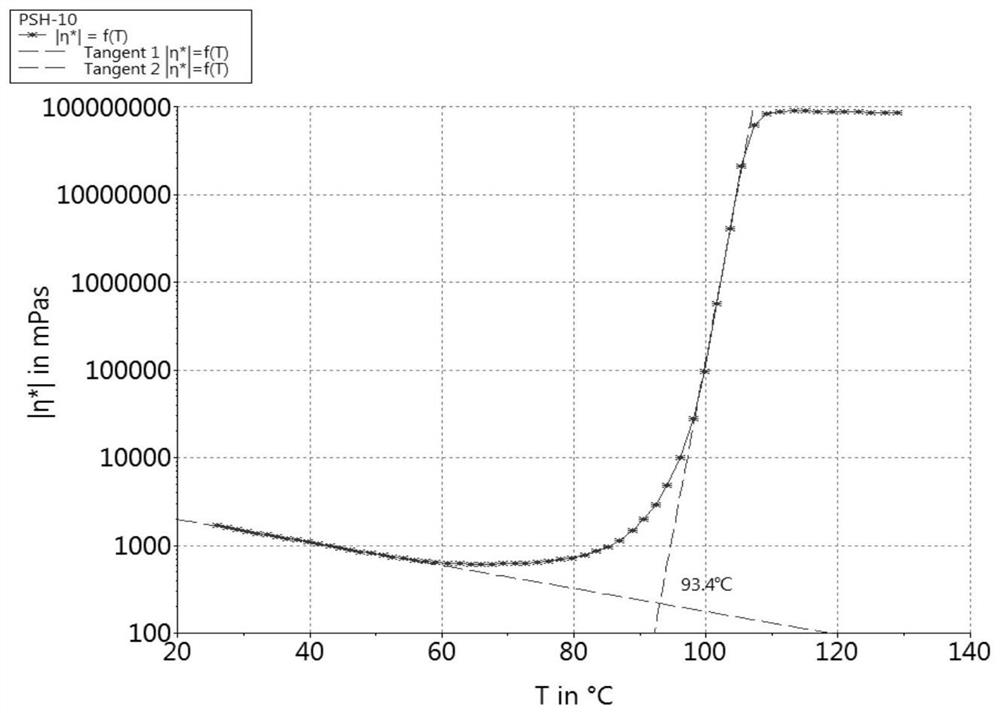

[0037] Among them, the polyvinyl chloride paste resin is PSH-10 resin powder.

[0038] By determining the tangent of two sharply changing curve segments on the viscosity-temperature curve corresponding to the polyvinyl chloride paste resin heated at a fixed heating rate, and then determining the temperature corresponding to the intersection of the two tangents as polyvinyl chloride paste resin The gel temperature of vinyl chlori...

Embodiment 2

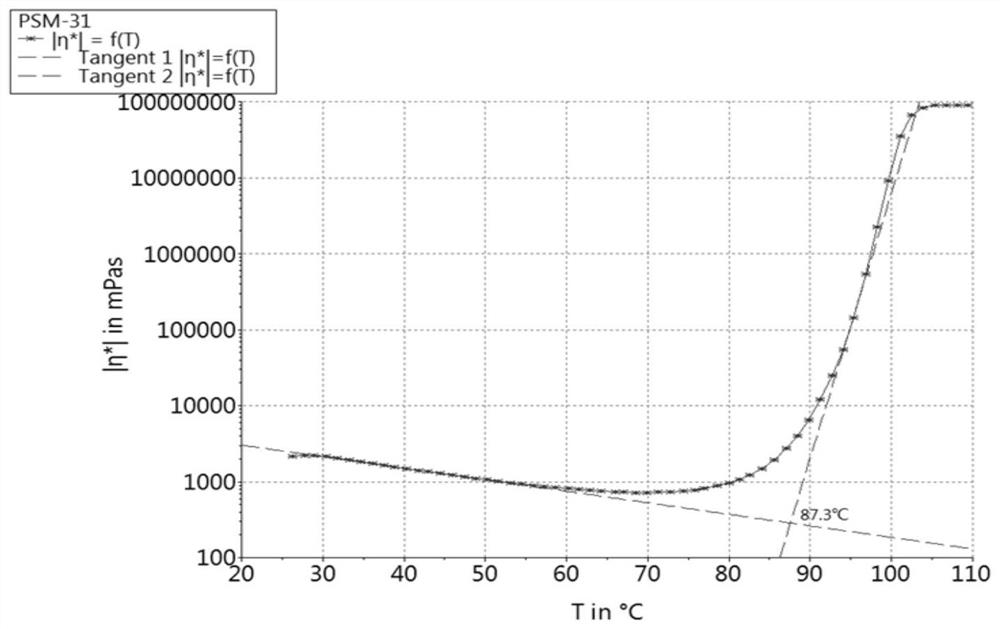

[0053] The difference between this embodiment and the gel temperature test method for polyvinyl chloride paste resin in embodiment 1 is that the polyvinyl chloride paste resin in this embodiment is PSM-31 resin powder.

[0054] figure 2It is the viscosity-temperature curve of PSM-31 resin powder. By determining the tangent of the two sharply changing curves on the viscosity-temperature curve, it can be concluded that the gel temperature of PSM-31 resin powder is 87.3°C .

Embodiment 3

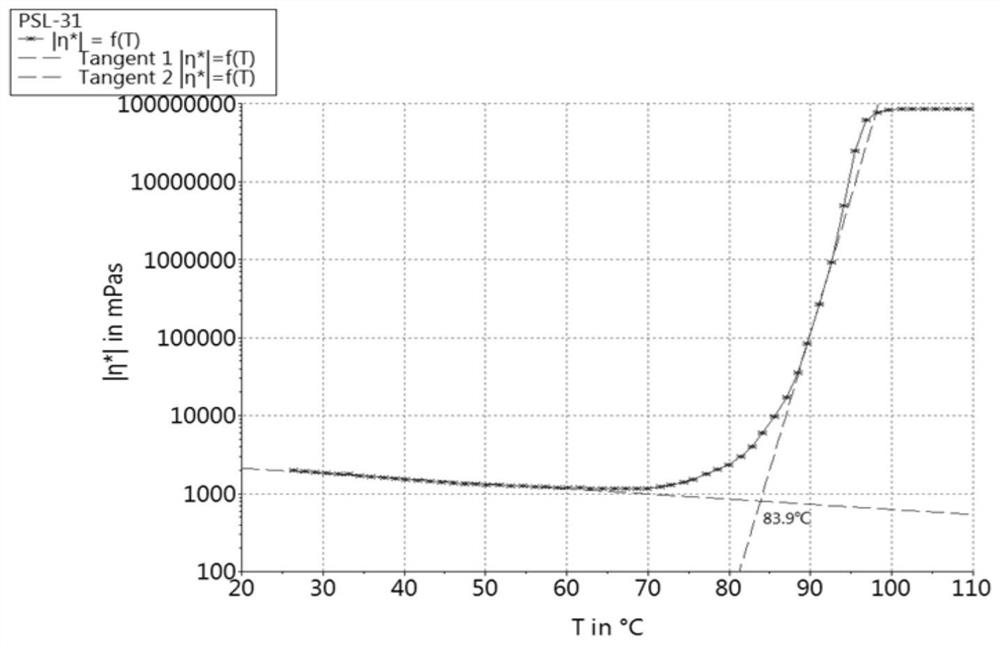

[0056] The difference between this embodiment and the gel temperature test method for polyvinyl chloride paste resin in embodiment 1 is that the polyvinyl chloride paste resin in this embodiment is PSL-31 resin powder.

[0057] image 3 It is the viscosity-temperature curve of PSL-31 resin powder. By determining the tangent of the two sharply changing curves on the viscosity-temperature curve, it can be concluded that the gel temperature of PSL-31 resin powder is 83.9°C .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com