System and method for trimming edge polishing pad

A technology for trimming edges and polishing pads, which is applied in the system field of trimming edge polishing pads, and can solve problems such as wafer edge quality degradation, wafer edge polishing unevenness, and reduced processing efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

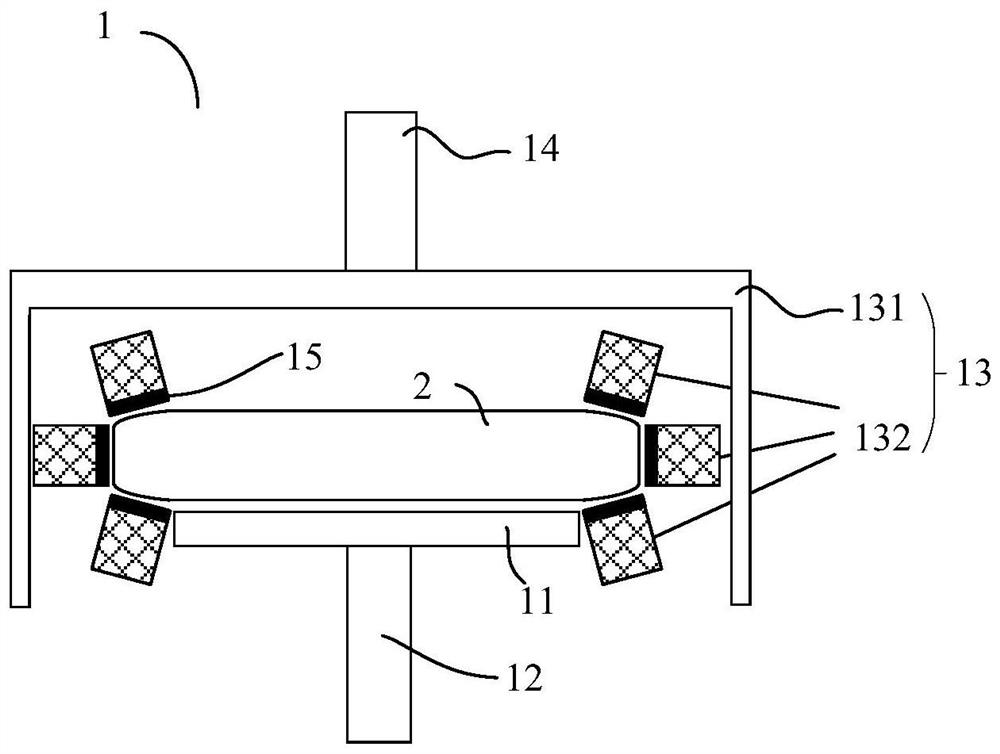

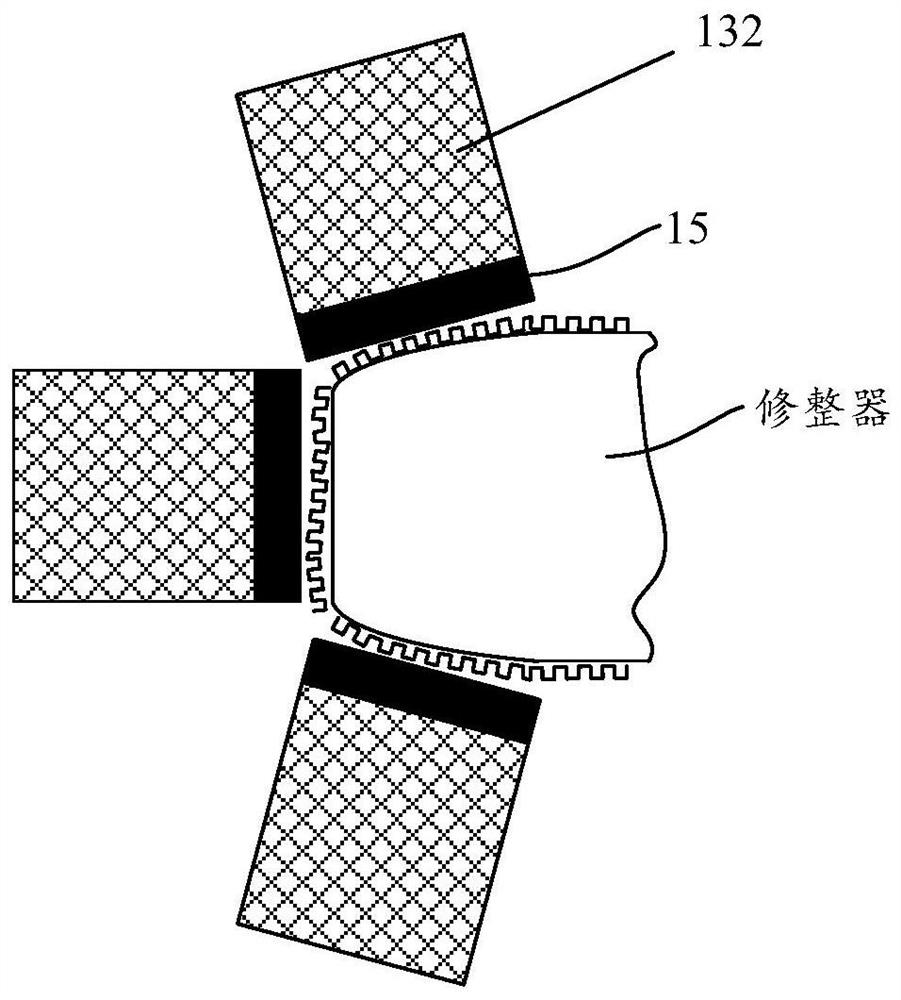

[0017] In the round edge polishing process unit in the edge polishing process, because the polishing object is the edge round edge of the wafer rather than the surface plane of the wafer, correspondingly, the structure of the equipment 1 for performing the round edge polishing process unit is as follows figure 1 As shown, it includes: a fixed base plate 11 for placing and fixing the wafer 2 to be polished, a first transmission rod 12 rigidly connected with the fixed base plate, a polishing head 13 and a second transmission rod 14 rigidly connected with the polishing head 13 Wherein, the polishing head 13 comprises: the housing 131 that forms open space and the multiple groups of polishing pad bottom plates 132 arranged in the vertical direction on the inner edge of the housing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com