Novel TRC permanent formwork steel-concrete composite beam and preparation method thereof

A permanent formwork and concrete technology, applied in the field of composite beams, can solve the problems of easy corrosion and fire resistance of steel-concrete composite beams, and achieve the effects of avoiding excessive deformation or damage, simplifying the construction process and improving the construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

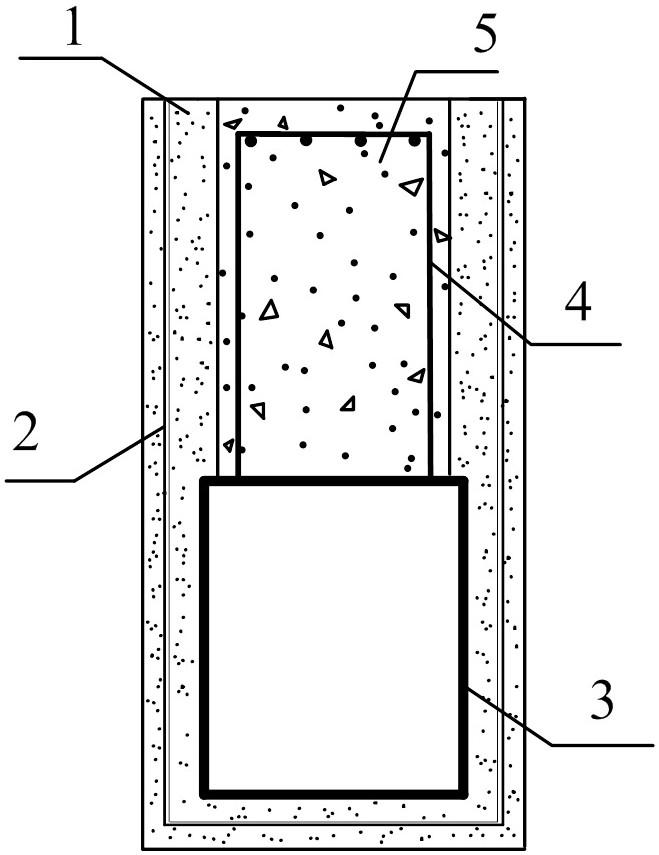

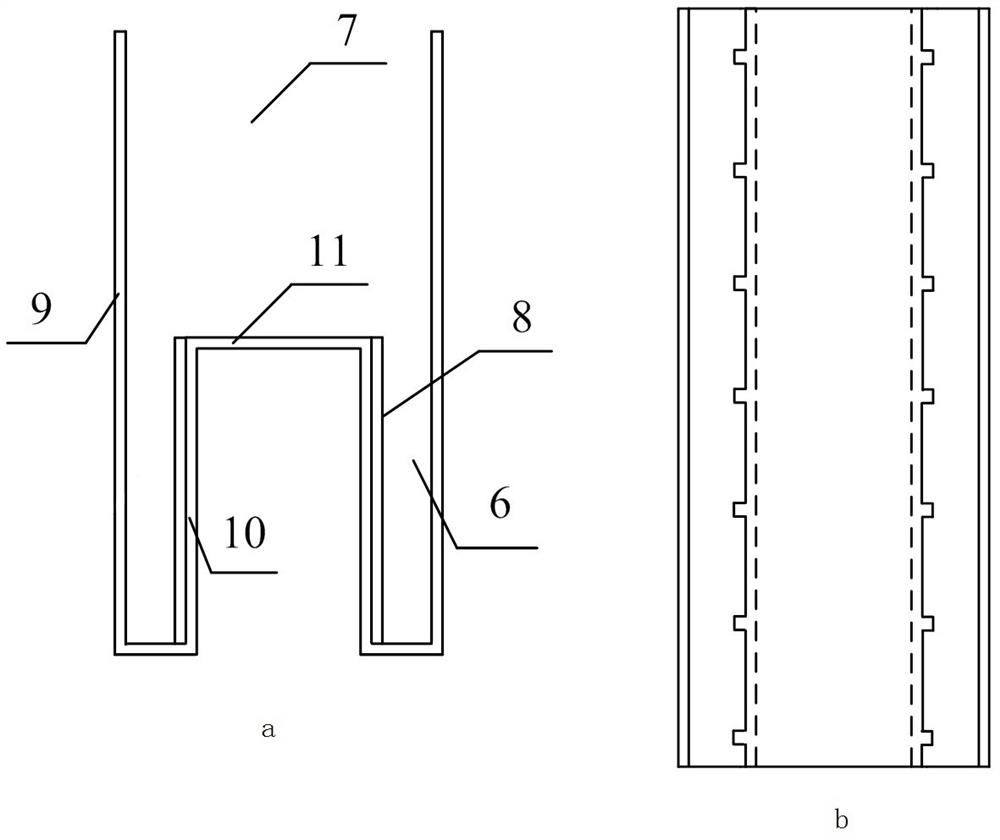

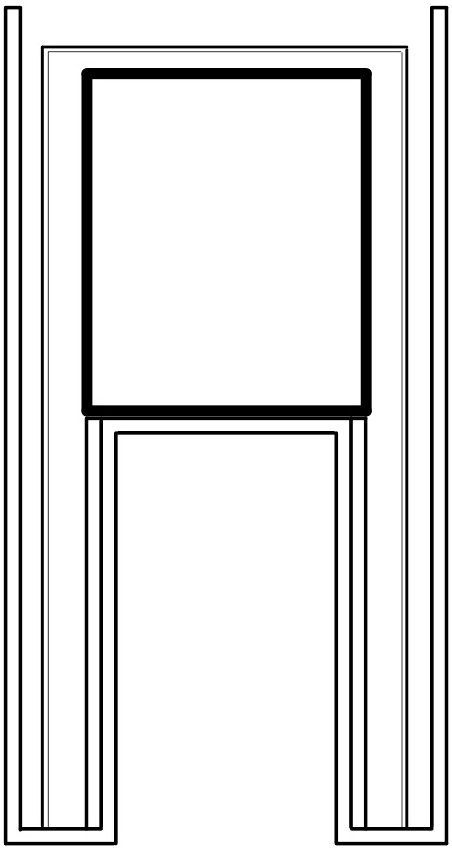

[0038]A new type of TRC permanent formwork steel-concrete composite beam, said new TRC permanent formwork steel-concrete composite beam is composed of high-performance fine aggregate concrete 1, fabric mesh 2 fixed by stainless steel plate mesh lining, box-shaped steel beam 3, and steel skeleton 4. It consists of cast-in-place concrete 5, side mold cavity 6, upper mold cavity 7, raised corrugated bar 8, outer plate 9, inner plate 10, and inner horizontal plate 11. The inner plate 10 and outer plate 9 are respectively provided with two The inside boards 10 and the outside boards 9 are all arranged in parallel, the two inside boards 10 are arranged between the two outside boards 9, the bottoms of the two inside boards 10 are connected with the bottoms of the two outside boards 9, and the tops of the two inside boards 10 Connected by the inner horizontal plate 11, the side mold cavity 6 is formed between the inner side plate 10 and the outer side plate 9, and the upper mold cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com