Resistance type level instrument with adjustable dielectric resistance area

A dielectric resistance and resistance technology, applied in the field of resistance level meter, can solve the problems of liquid height measurement error, slow liquid discharge speed, etc., and achieve the effect of reducing bearing force, accelerating discharge, and speeding up moving speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

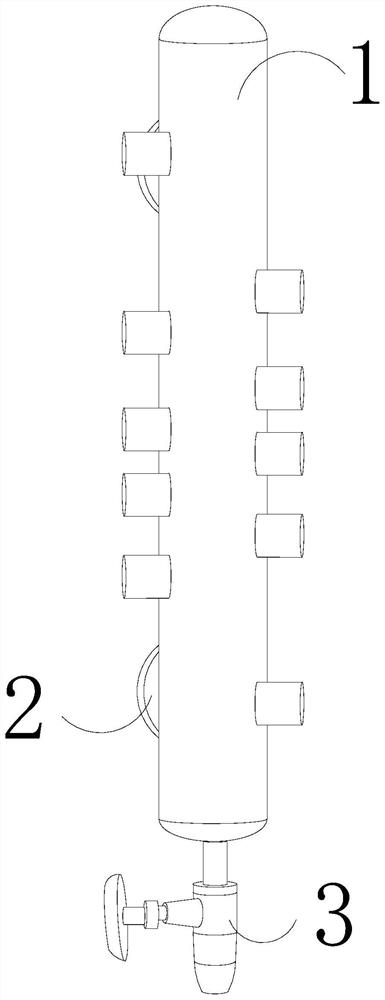

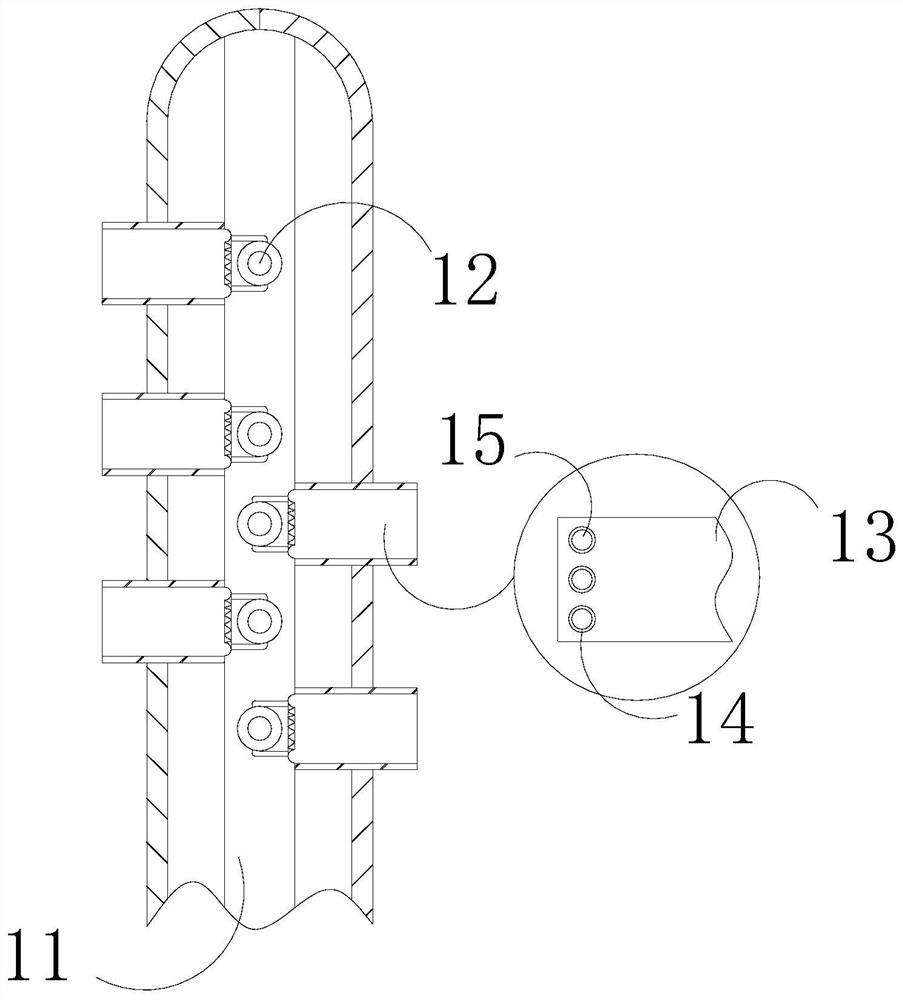

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The present invention provides a resistive level meter with adjustable medium resistance area. Its structure includes a pipe body 1, a fixed flange 2, and a drain pipe 3. The fixed flange 2 is horizontally welded on the back of the pipe body 1. The drain pipe 3 is vertically installed at the bottom of the pipe body 1 .

[0027] The tube body 1 is provided with a support tube 11, a lamp bead 12, a liquid inlet tube 13, an opening 14, and a pushing mechanism 15. The support tube 11 is vertically fixed in the middle of the tube body 1, and the lamp bead 12 is installed on the support tube 11 front, the liquid inlet pipe 13 runs through both sides of the pipe body 1 and connects with the lamp bead 12, the opening 14 runs through the upper and lower surfaces of the inner end of the liquid inlet pipe 13, and the pushing mechanism 15 is set inside the opening 14.

[0028] Wherein, the pushing mechanism 15 is provided ...

Embodiment 2

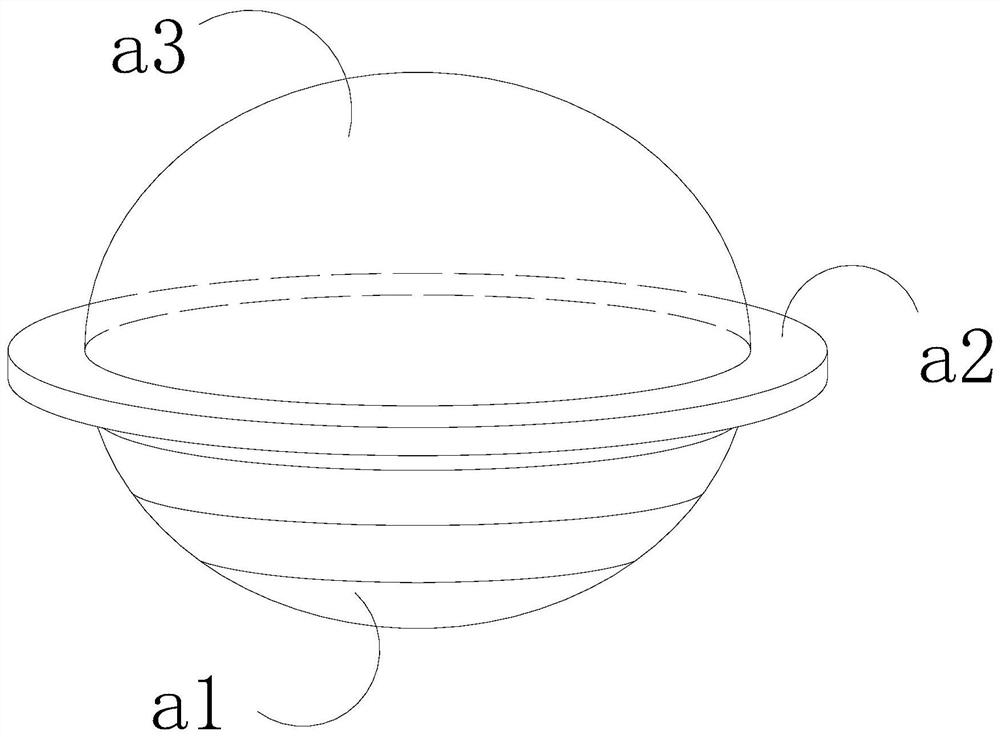

[0034] as attached Figure 6 to attach Figure 7 Shown:

[0035] Wherein, the clamping plate a2 is provided with a support plate r1, a drainage groove r2, and a drain hole r3, the drainage groove r2 is recessed on the upper surface of the support plate r1, and the drain hole r3 runs through the upper and lower surfaces of the support plate r1, and is connected to the upper surface of the support plate r1. The drainage groove r2 is connected, and the drainage groove r2 is inclined from the outside to the middle, which is beneficial to reduce the resistance to the liquid and accelerate the flow of the liquid along the slope into the drain hole r3. The drain hole r3 is provided with eight One, it is beneficial to speed up the flow of liquid along the drain hole r3, slow down the gravity of the clamping plate a2, and further accelerate the moving speed of the pushing mechanism 15 up and down.

[0036] Wherein, the drainage hole r3 is provided with a drainage hole t1, a groove t2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com