Liquid phase pump system integrated control system and method for multi-shaft coupling cooperative motion

A technology of integrated control system and coordinated motion, applied in general control system, program control, computer control and other directions, can solve the problem of poor synchronization of multi-axis control, and achieve the effect of reducing the number and reducing the interference of communication signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

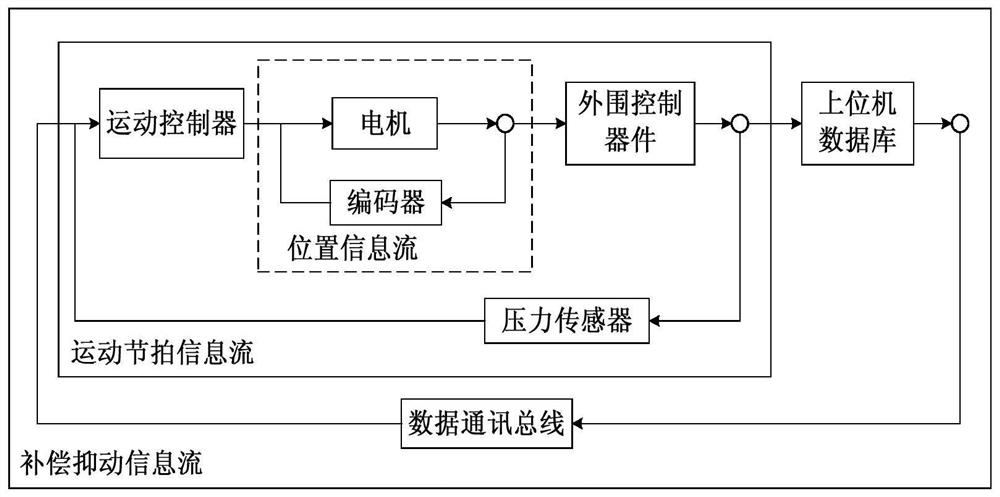

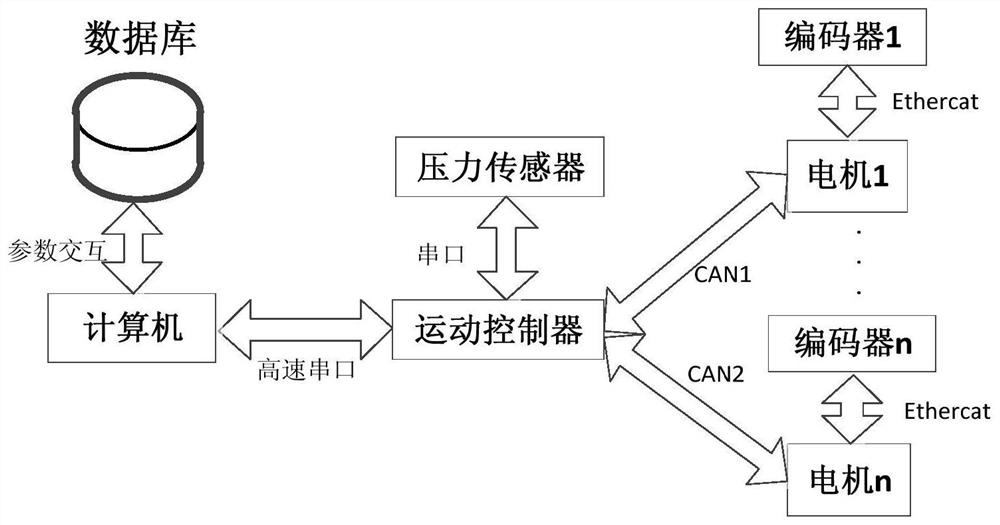

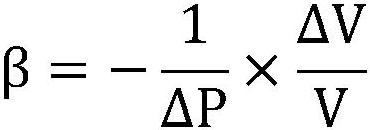

[0037] The system flow accuracy index is RSD=0.06%, the pulsation rate index is 0.3MPa, and the maximum operating pressure of the system is 120MPa. For example, the change of the mixing ratio of different liquids during the operation of the liquid phase pump will lead to changes in the system pressure. In order to ensure the smoothness of the gradient curve and the accuracy of the concentration ratio, it is necessary to change the motion parameters of the multi-axis motor in each cycle. The accuracy and low pulsation of the process flow, the multi-axis motion need to maintain a certain coupling coordination and the compression coefficient needs to be adjusted dynamically. Therefore, the entire control system must realize the rapidity and accuracy of information flow transmission to ensure that the concentration ratio of the gradient process is accurate and stable according to the set method.

[0038] Such as figure 1 As shown, an integrated control system for a liquid phase p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com