Transverse variable doping terminal structure, design method and preparation method

A terminal structure and design method technology, applied in design optimization/simulation, semiconductor/solid-state device manufacturing, special data processing applications, etc., can solve problems such as low efficiency and difficulty in achieving optimal design, and achieve simple and uniform surface electric field distribution, the effect of improving the doping concentration distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

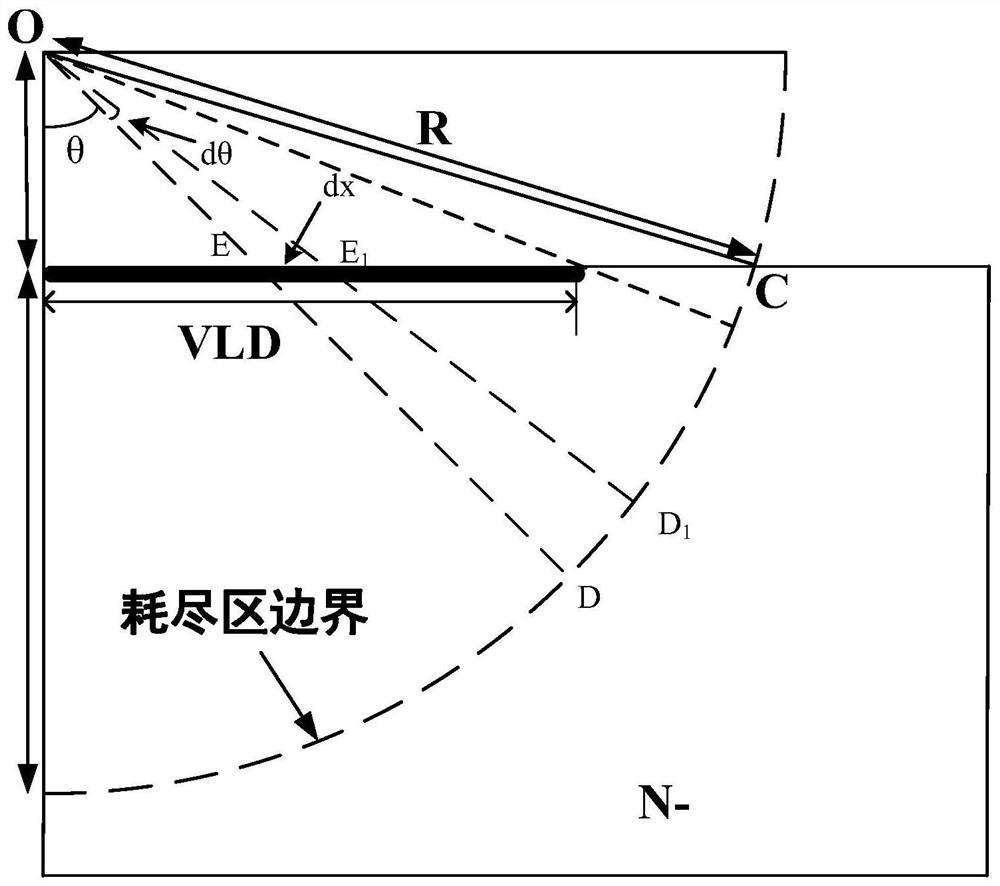

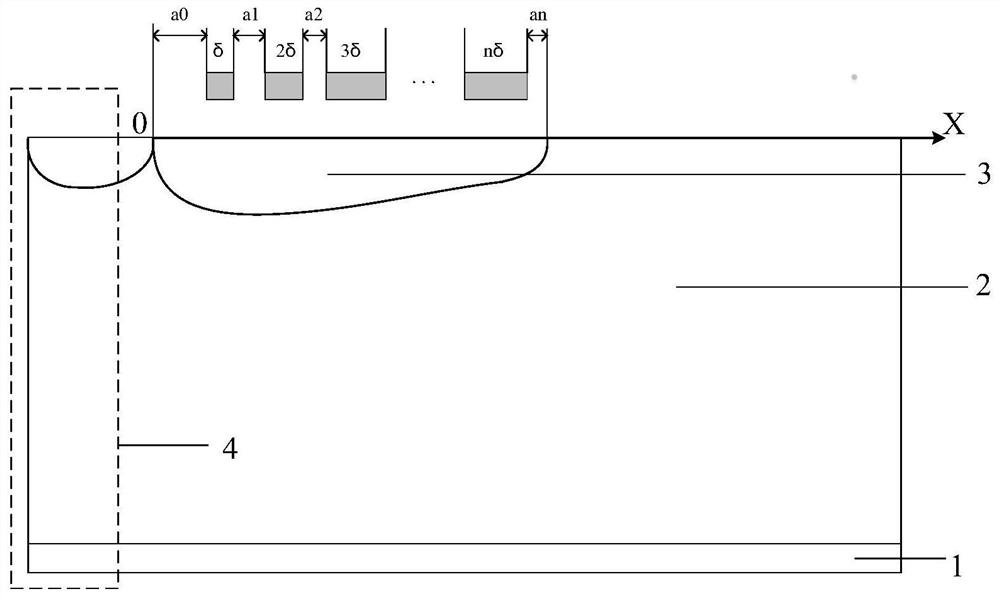

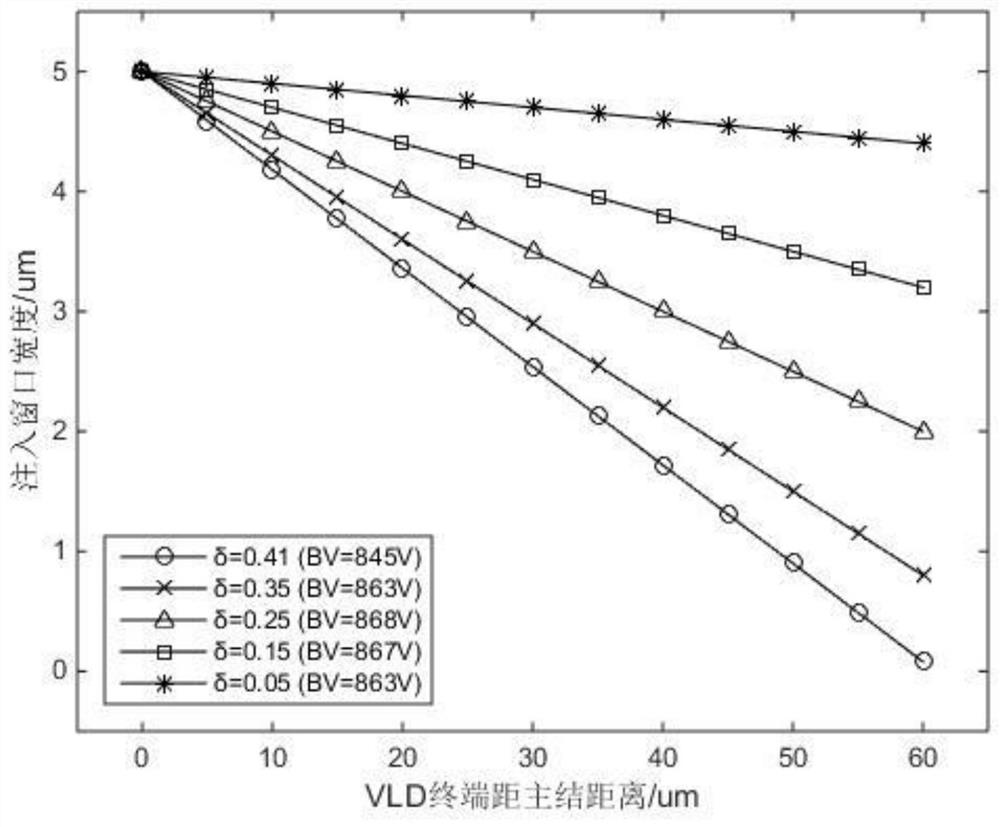

[0043] Design a lateral variable doping structure that meets the withstand voltage of 800V. Such as figure 2As shown, it includes a heavily doped first conductive type semiconductor substrate 1, a first conductive type semiconductor drift region 2 on the upper surface of the heavily doped first conductive type semiconductor substrate 1, and the first conductive type semiconductor drift region 2 The second conductivity type semiconductor terminal region 3 on the upper surface, the doping concentration of the first conductivity type semiconductor drift region 2 is N D , taking the starting position of the terminal region 3 of the second conductivity type near the active region 4 as the coordinate origin, and taking the upper surface of the semiconductor termination region 3 of the second conductivity type as the x-axis, so as to be close to the active region 4 of the device On the side of the region 4, pointing away from the active 4 side of the device is the positive directio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap