Low Voltage Stacked Lithium Niobate Electro-optic Q-Switch

A lithium niobate, low-voltage technology, applied in the field of pulsed laser Q-switching devices, can solve the problems of low half-wave voltage and large optical aperture, high half-wave voltage, etc., to meet the needs of high-power lasers and overcome the crystal growth size The effect of the restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

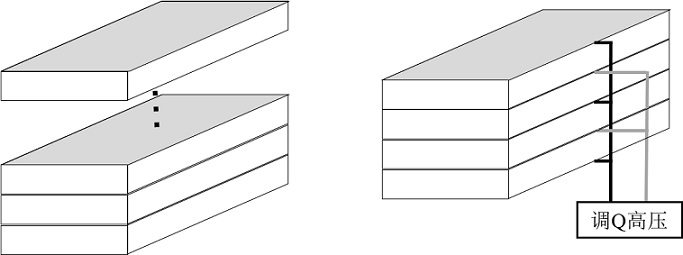

[0025] A low-voltage stacked lithium niobate electro-optic Q switch, which is formed by stacking three rectangular lithium niobate crystal sheets, each crystal has a size of 3mm×9mm×18.8mm ( x x y x z ), z The axial direction is the direction of light transmission, x The axial direction is the direction of the electric field, and the specific steps are as follows:

[0026] (1) In order to reduce the axial deviation of the three crystals, first cut the crystal orientation into a size of 9mm×9mm×18.8mm ( x x y x z ) of the rough block, directional grinding on each side, and z The surface is roughly polished, and then the crystal is cut into three pieces according to the required size, and the cutting surface is directional ground, and then the chamfering angle of each crystal along the length direction is C0.5;

[0027] (2) Mark the positive and negative directions of each axis of the crystal, and each x The surface is polished and plated with Au / Ti electrodes, and the t...

Embodiment 2

[0031] A low-voltage stacked lithium niobate electro-optical Q switch, which is formed by laminating two rectangular lithium niobate crystal slices, and each crystal has a cut shape of , the size is 4.5mm×9mm×18.8mm (thickness t ×width b × length l ), the length direction is the direction of light transmission, and the thickness direction is the direction of electric field application. The specific steps are as follows:

[0032] (1) In order to reduce the axial deviation of the two crystals, the crystals are first The cutting direction is cut into a size of 9mm×9mm×18.8mm (thickness t ×width b × length l ) of the rough block, directional grinding on each surface, and roughly polishing the two ends of the length direction, then cutting the crystal into two pieces according to the required size, directional grinding on the cutting surface, and then chamfering the edges of each crystal along the length direction C0.5;

[0033] (2) Mark the positive and negative direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com