Negative pressure environment bone cement single hole injection fracture fixation system and working method

A fixation system and bone cement technology, applied in fixator and other directions, can solve problems such as needle eye reaction, enlarged incision, blood supply damage, etc., to avoid internal or external damage, improve fixation effect, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

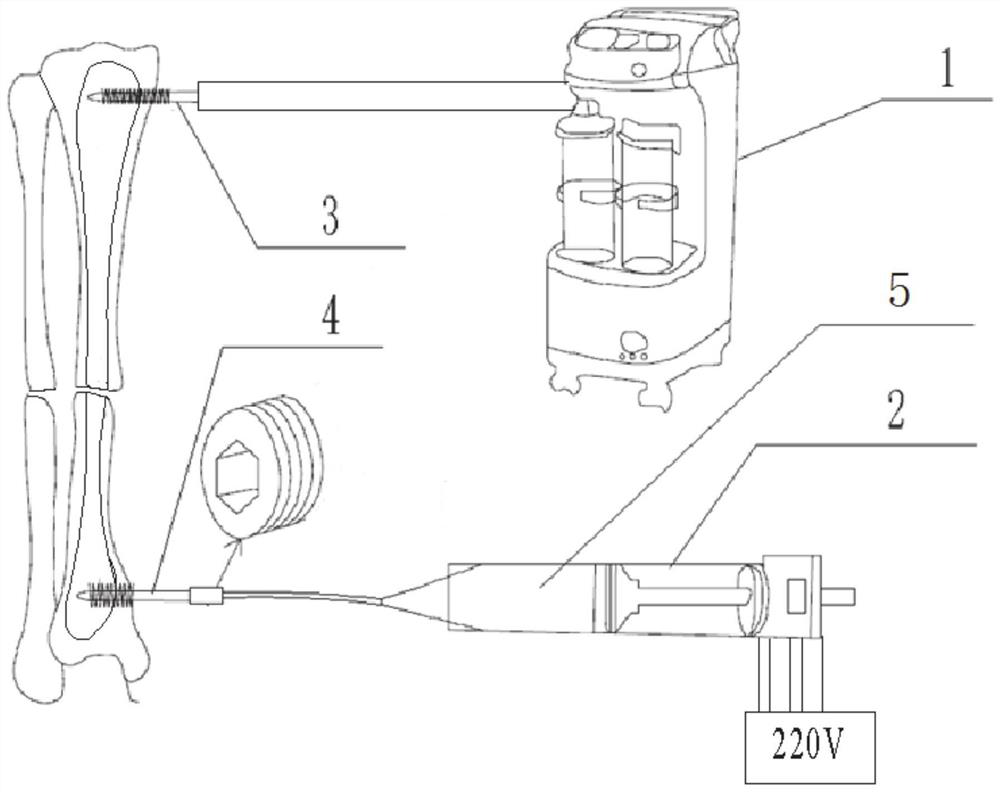

[0050] In this embodiment, the negative pressure device is a vacuum device.

[0057] In the present embodiment, the outer surface of the second end of the second hollow nail is a threaded structure, which is used for drilling a bone.

[0058] In this implementation, the bone cement injection device is an electric bone cement injector.

Embodiment 2

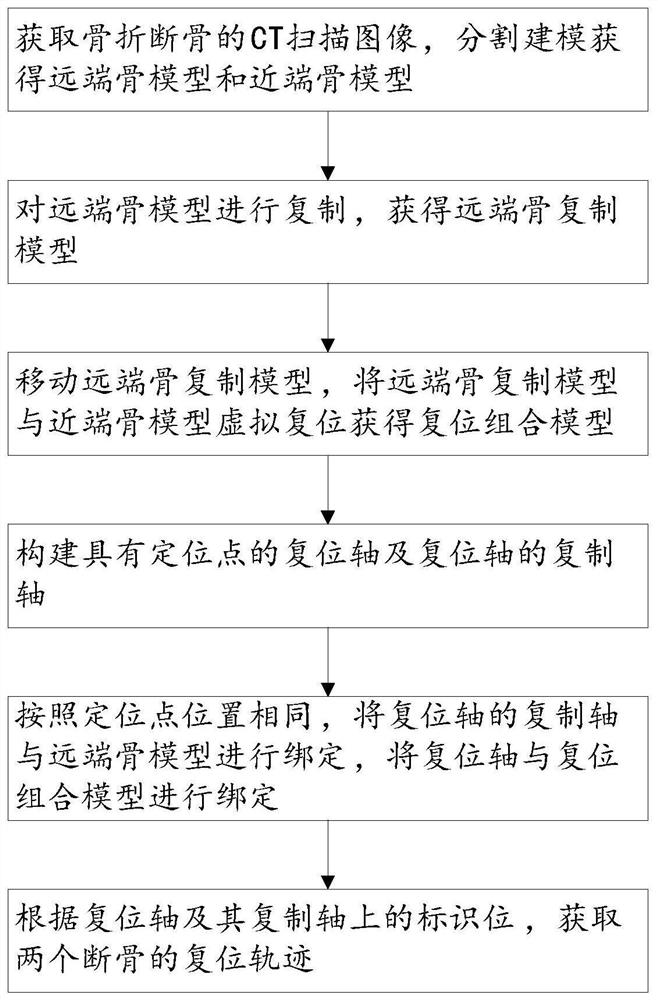

[0072] Step 6: According to the positioning point on the reset axis and its replication axis, obtain the reset trajectory of the two broken bones.

[0087] For ease of operation, the reduction axis and the replication axis can be set parallel to the fractured bone.

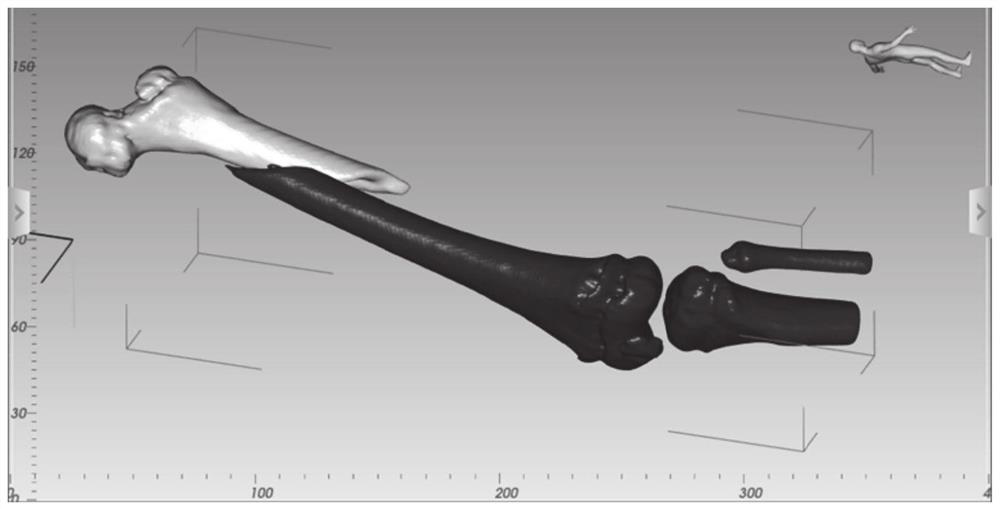

[0088] Specifically, the reset axis can be a cylinder model, and the positioning point is a sphere or a cylinder model. As shown

[0091] In step 6, according to the positioning point on the reset axis and its replication axis, obtain the reset trajectory of two broken bones.

[0102] Those skilled in the art will appreciate that embodiments of the present disclosure may be provided as methods, systems, or computer programs

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com