A kind of reactor feeding device for chlorinated paraffin production

A technology of chlorinated paraffin and feeding device, which is applied in feeding device, mixer with rotary stirring device, transportation and packaging, etc., can solve the problems affecting the production quality of chlorinated paraffin, stirring of liquid paraffin, and the reaction effect of paraffin and chlorine gas. Poor and other problems, to achieve good shock absorption effect, quiet production environment, and improve the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

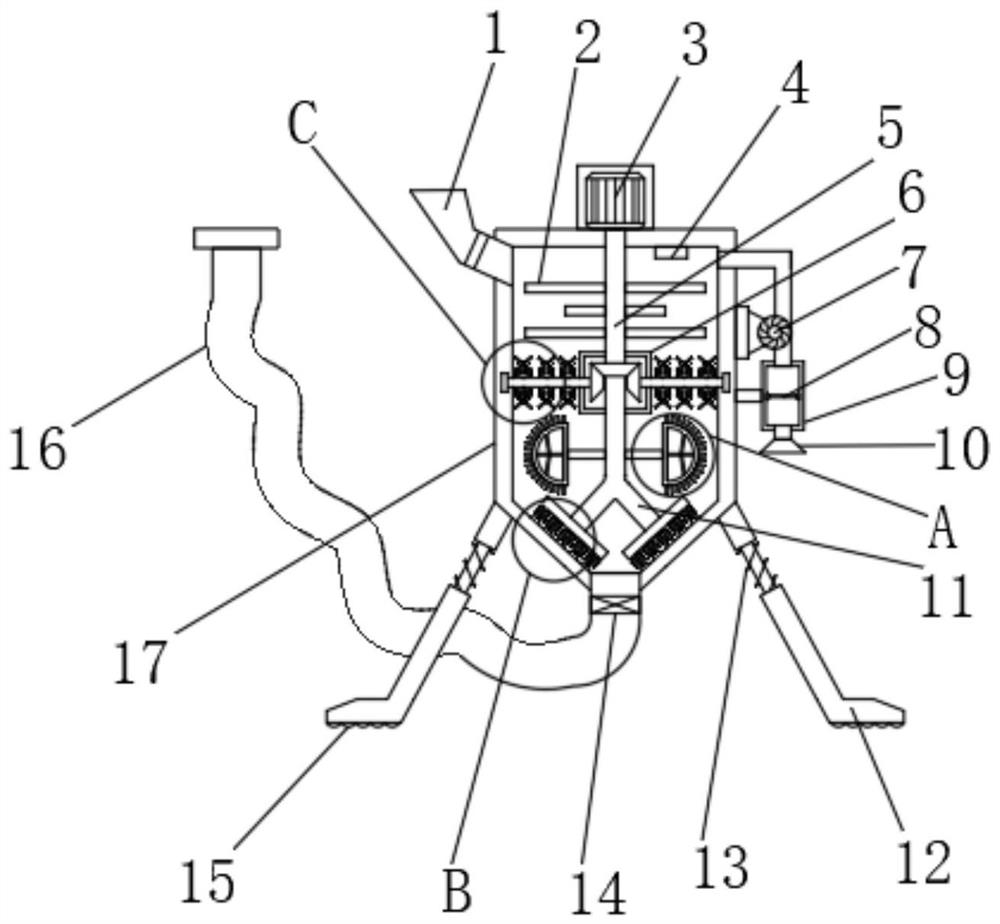

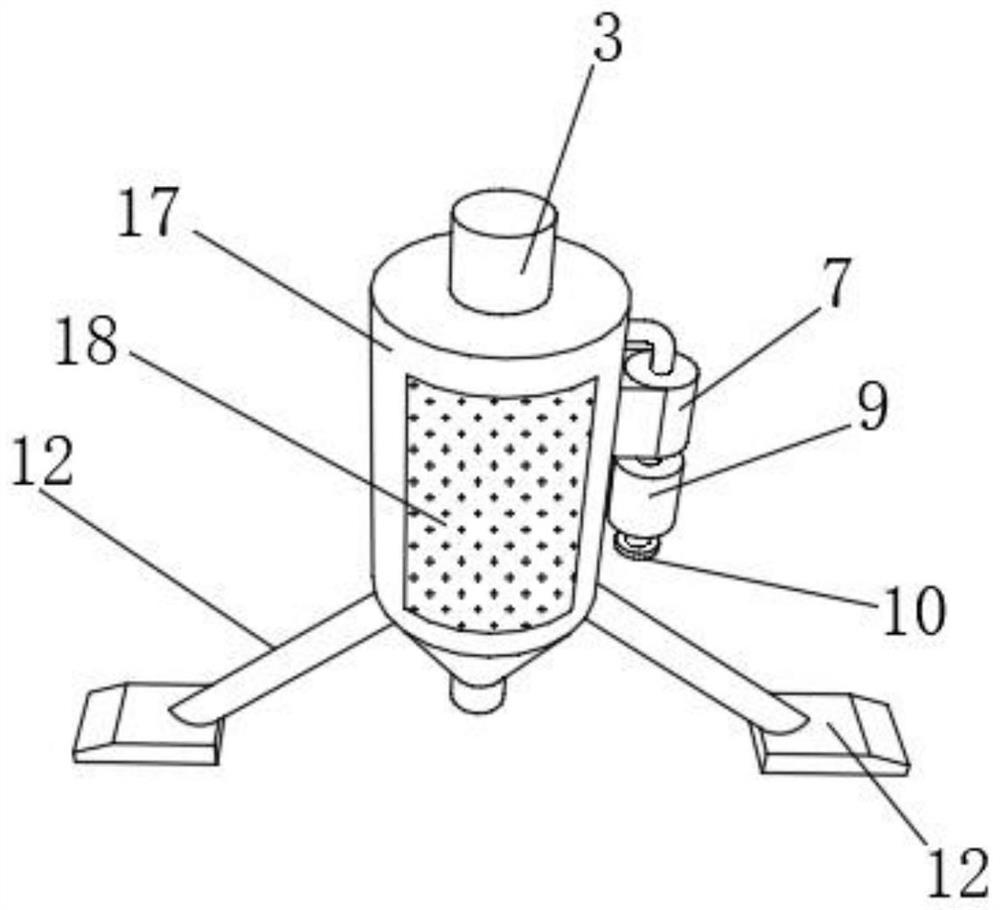

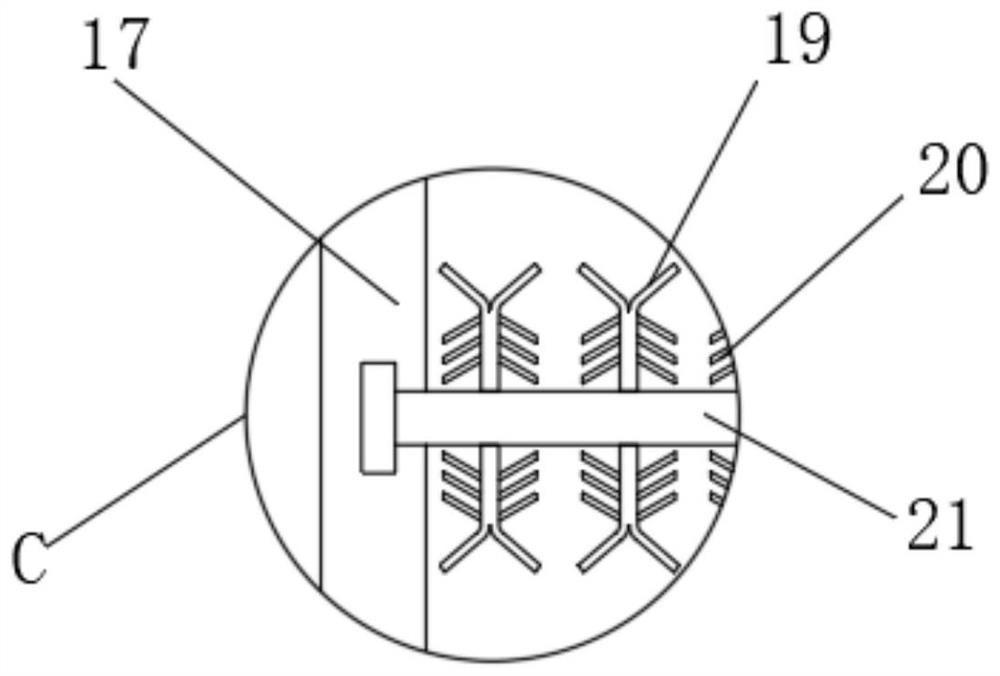

[0028] Reference Figure 1-5, a reaction kettle feeding device for the production of chlorinated paraffin wax, comprising a mixing box 17, the top outer wall of the mixing box 17 is fixed with a motor 3 by a screw, and the output shaft of the motor 3 is connected to the stirring rod 5 through the coupling, the bottom end of the stirring rod 5 is socketed with a first bevel gear, and the bottom end of the first bevel gear is fixed by a screw Y rod 11, Y-rod 11 is far from the end of the first bevel gear is fixed by a screw 26, and the outer wall of the mounting rod 26 is welded with a fixed rod with an equal distance distribution 25, The outer wall of the fixing rod 25 is welded with an equal distance distribution of the arc rod 27, and the fixing rod 25 is provided with a scraper 28 at one end away from the mounting rod 26, the scraper 28 forms a sliding fit with the bottom inner wall of the mixing box 17, the outer walls of both sides of the Y-rod 11 are provided with a connecting...

Embodiment 2

[0038] Reference Figure 1 , a reaction kettle feeding device for the production of chlorinated paraffin waxes, compared to Example 1, further comprising the top inner wall of the mixing box 17 is fixed by a screw with a pressure sensor 4, and the signal output of the pressure sensor 4 is connected to the processor via a signal line.

[0039] Pressure sensor 4 can detect the air pressure in the mixing box 17, can change the value of the air pressure to control the rate of feeding, improve the convenience of worker operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com