Deslagging method for shipbuilding plasma cutting platform

A cutting platform, plasma technology, applied in the direction of plasma welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of high investment cost, damage to the steel plate protective paint, reduce the quality of parts, etc., to achieve good slag removal effect, slag removal The effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

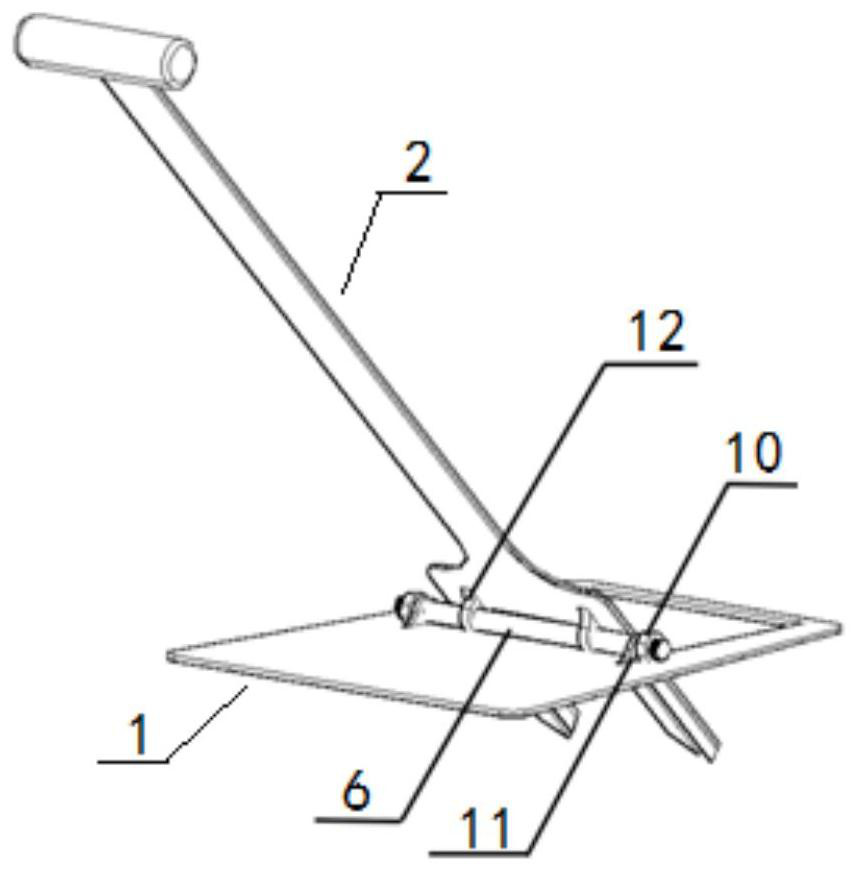

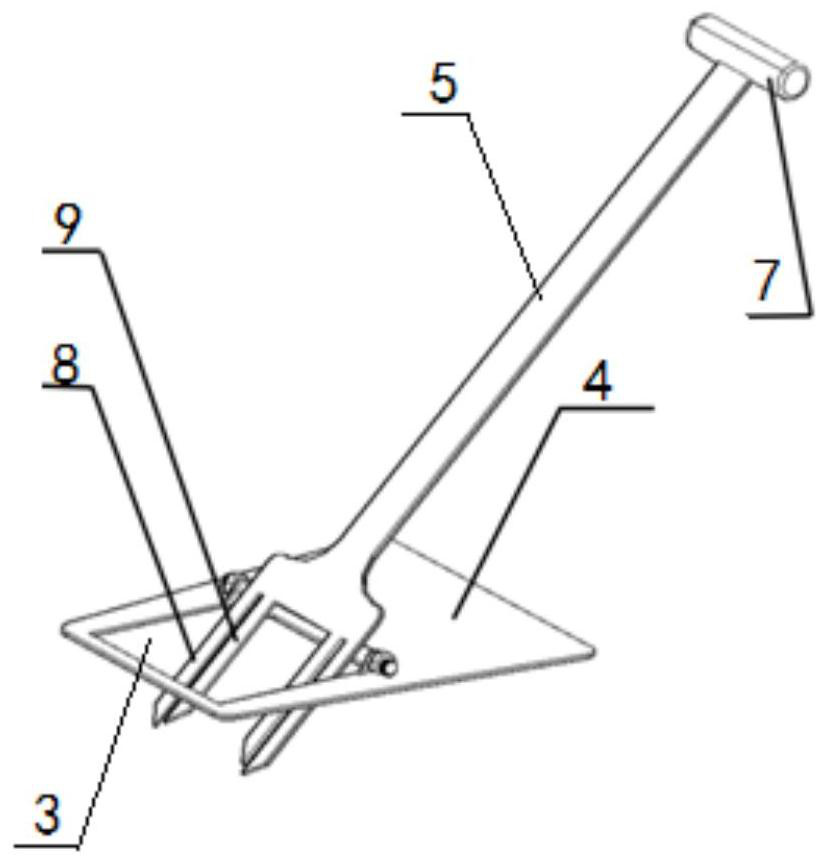

[0028] This embodiment provides a slag removal device for a shipbuilding plasma cutting platform, which includes a support part 1 and a slag removal part 2, and the support part 1 and the slag removal part 2 are integrally formed. The support part 1 is a flat plate, and one side of the support part 1 is provided with a rectangular installation hole 3, and the support part 1 on the opposite side of the installation hole 3 is a support platform 4, and the side of the support platform 4 connected to the installation hole 3 is installed with a shaft 6.

[0029] The slag removal part 2 includes a slag removal rod 5 and a slag removal head. The slag removal head is arranged at the end of the slag removal rod 5. Both sides of the slag removal rod 5 are provided with a first saber tooth 8 and a second saber tooth 9. A slag-removing tooth groove is formed between one saber tooth 8 and the second saber tooth 9, and the slag-removing tooth groove is used for snapping the sword bars, and ...

Embodiment 2

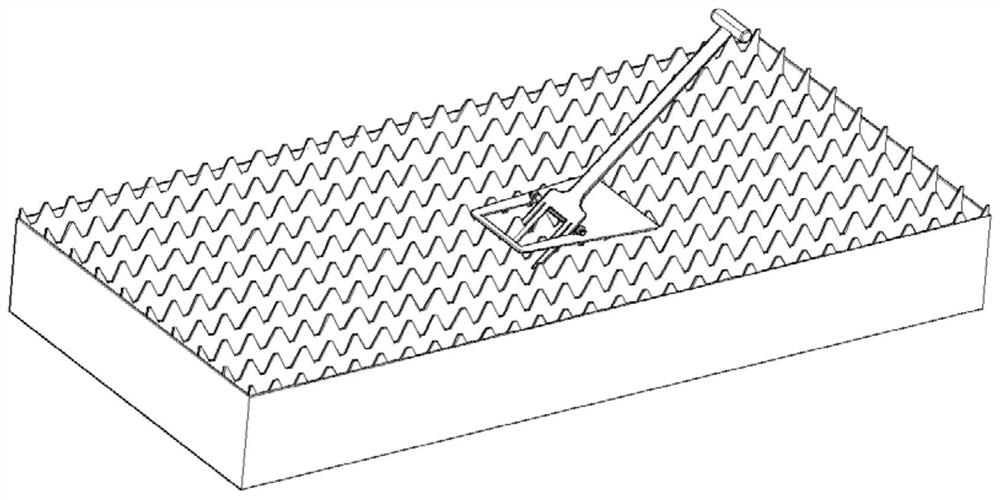

[0034] This embodiment provides a method for removing slag on a plasma cutting platform for shipbuilding, including the following steps:

[0035] Select the direction in which the sword grid bars of the plasma cutting platform are continuously penetrated, place the tooling, adjust the placement position, and rotate the slag removal rod 5 so that the two first saber teeth 8 can fall on the outer sides of the two adjacent sword grid bars, so that the two second sword teeth The second saber tooth 9 can fall on the inner side of two adjacent sword bars. After turning the slag removal lever 5 to make the slag removal alveolar reach the bottom, turn the slag removal lever 5 again to make the slag removal alveolar rotate upwards to clean out the slag removal alveolar. The molten slag on the sword bars causes the support platform 4 to lose stability up and down at the same time, so that the device moves forward and reciprocates to achieve the effect of cleaning the molten slag.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap