Gap clamping machine for magnetic card head production and gap piece clamping method

A magnetic head and magnetic card technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low installation efficiency, difficult installation, affecting performance, etc., to ensure installation effect, improve installation efficiency, and ensure installation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

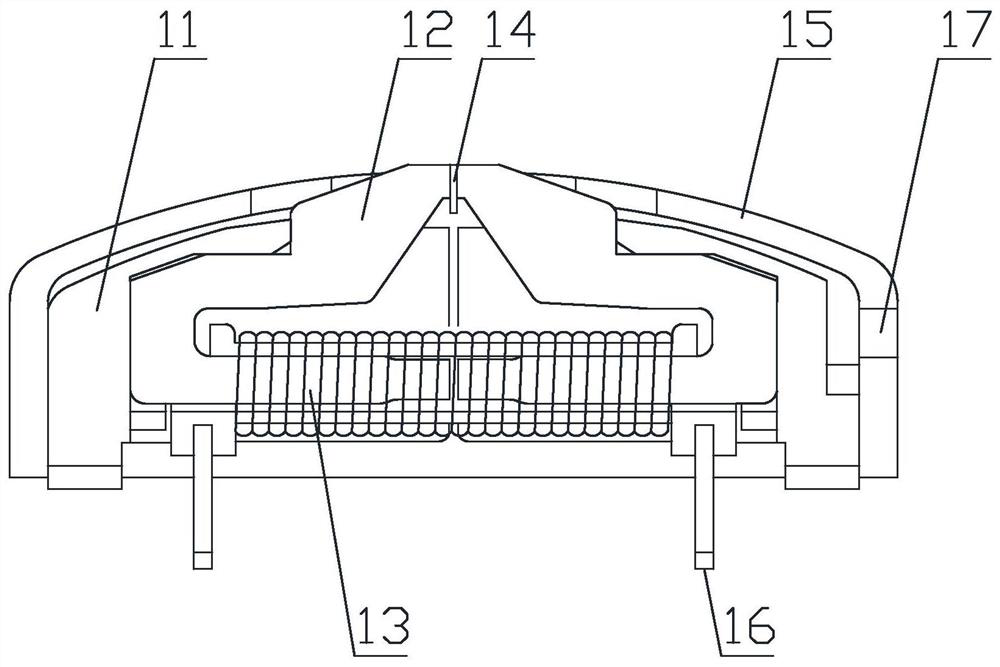

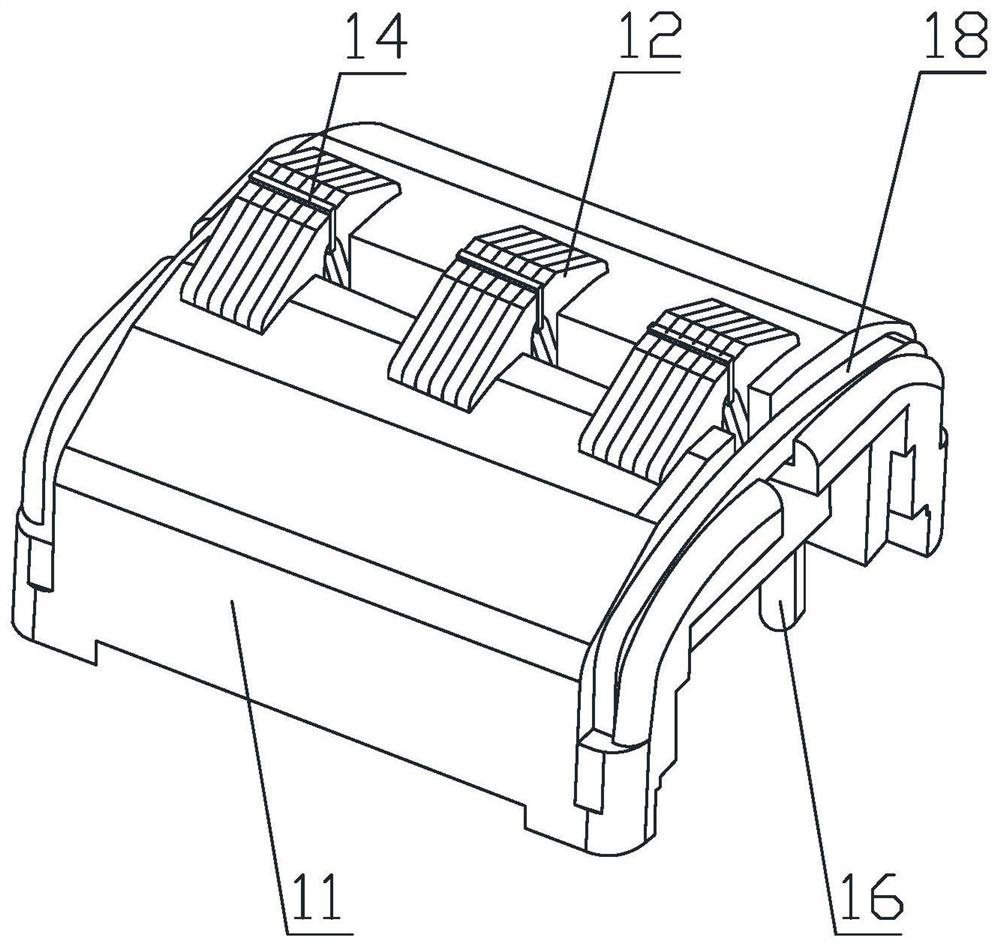

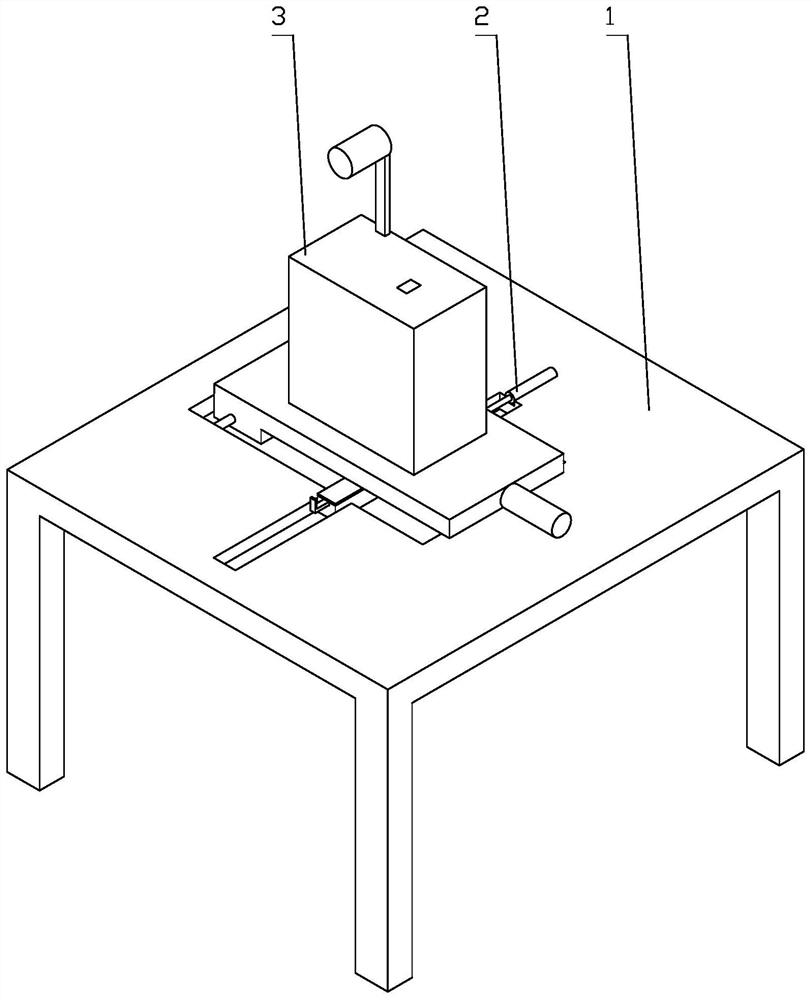

[0035] The clip gap machine for magnetic card and magnetic head production includes a base 1 and a titanium foil feeding unit 3 arranged on the base 1, a magnetic head assembly (here specifically refers to the combination of a holder, a magnetic core group and a wire package) feeding unit 2 and a clip holding unit 4,

[0036] Magnetic head assembly feeding unit 2 comprises first cylinder 2.1, the 4th cylinder 2.2, slide rail 2.3 that are fixedly arranged on base 1, and slide block 2.4 that is slidably arranged on slide rail 2.3, and slide block 2.4 top is provided with along its sliding direction The chute 2.5 is provided with a cover 2.6 on the top of the chute 2.5, and the cover 2.6 is provided with a groove 2.7 for holding the magnetic head assembly, and a movable rod 2.8 is provided for sliding in the chute 2.5, and one end of the movable rod 2.8 extends Out of the chute 2.5, the end of the movable rod 2.8 located in the chute 2.5 is provided with a magnet 2.9, the length ...

Embodiment 2

[0042] Utilize the clamp gap machine for magnetic card magnetic head production of embodiment 1 to operate the clamp gap of the magnetic head assembly. In the initial state, the slider 2.4 and the foil piercing port 3.6 are staggered, and the slide bar slides inward, and the drive magnet 2.9 is away from the groove 2.7, The titanium foil roll is rotated on the roller 3.3, the number of titanium foil rolls is determined according to the number of gaps held by each magnetic head assembly, and the end of the titanium foil is fed into the two delivery rollers 3.4;

[0043] First, put the magnetic head assembly in the groove 2.7, the gripper gap of the magnetic head assembly is consistent with the sliding direction of the slider 2.4, and the gap between the two grippers is widened;

[0044] Secondly, start the first cylinder 2.1, drive the slider 2.4 to slide, send the magnetic head assembly to the lower part of the foil hole 3.6, start the motor 3.5, drive the titanium foil to exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com