Efficient PPR pipe cutting device

A cutting device and high-efficiency technology, which is applied in metal processing and other directions, can solve the problems of inability to cut in batches and cannot be fixed, so as to achieve good cutting, improve work efficiency, and ensure the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

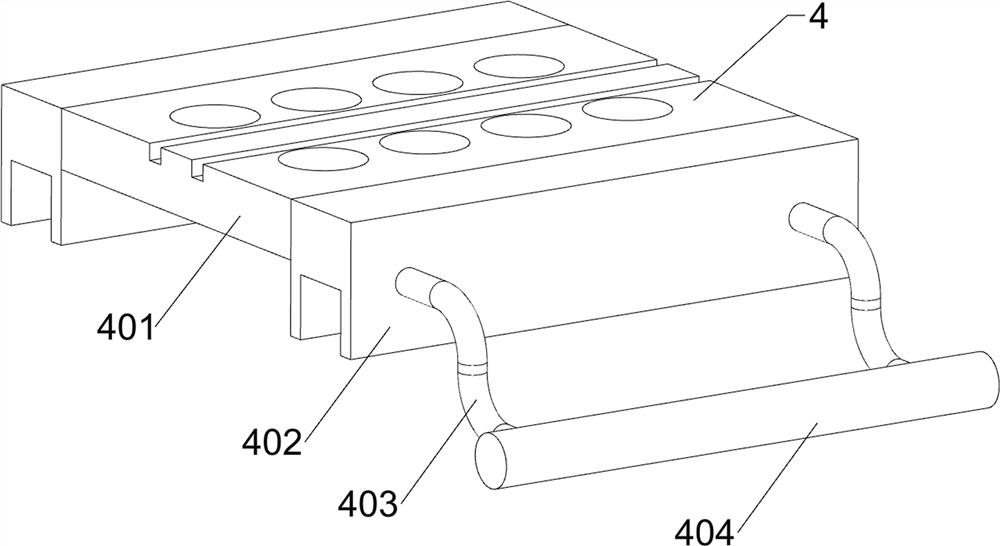

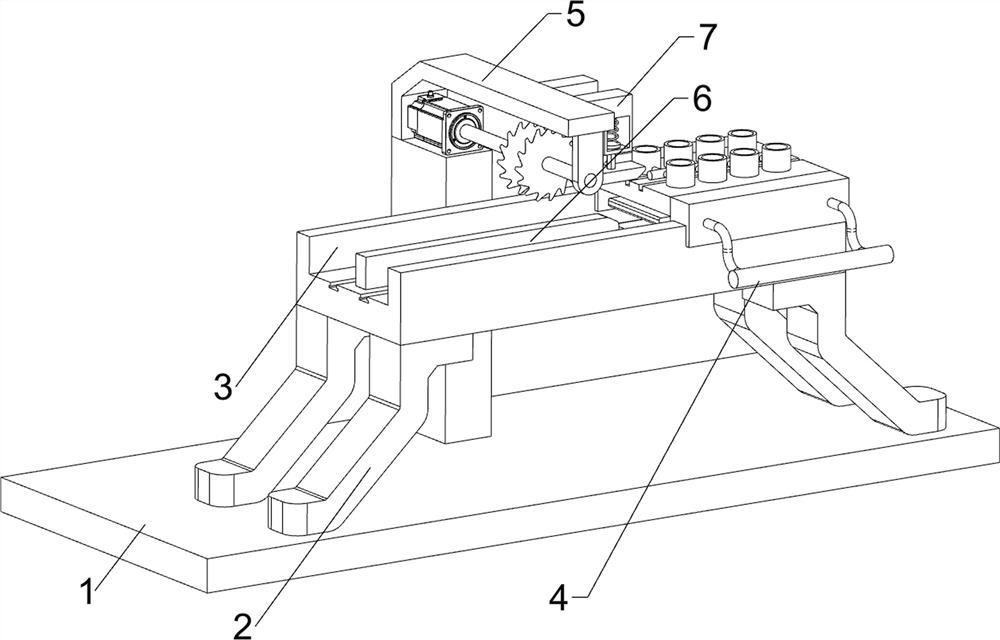

[0025] A kind of efficient cutting device for PPR pipe, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a first bracket 2, a workbench 3, a sliding assembly 4 and a cutting assembly 5. The left and right sides of the upper side of the base 1 are symmetrically connected with the first bracket 2, while the upper side of the base 1 is The first bracket 2 is also connected in the middle of the front part, and the workbench 3 is connected between the upper side of the first bracket 2 at the front part. The sliding assembly 4 is arranged on the upper right side of the upper part of the workbench 3, and the cutting assembly is arranged on the upper side of the first bracket 2 at the rear. 5.

[0026] When the user needs to cut the PPR tube, first put the PPR tube into the sliding assembly 4, start the cutting assembly 5, then push the sliding assembly 4 to move to the left, drive the PPR tube to move to the left to the cutting assembly 5, and complete the ...

Embodiment 2

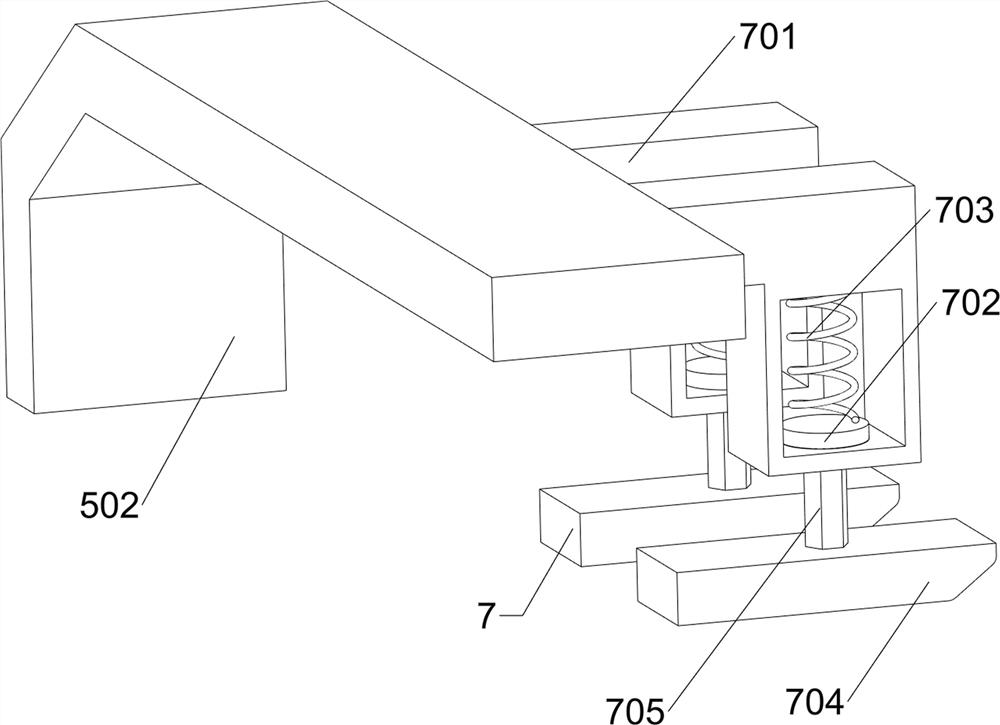

[0032] On the basis of Example 1, such as Figure 4 and Figure 5 As shown, it also includes a stabilizing assembly 6, and the stabilizing assembly 6 includes a first slide block 601, a first spring 602, a first movable plate 603, a first top block 604, a sleeve rod 605 and a first contact block 606, and the working table 3 The upper side of the lower part is connected with the first sliding block 601 in front and rear symmetrical sliding type, and the first spring 602 is connected with the left and right sides of the upper part of the first sliding block 601, and the first movable plate 603 is connected between the upper side of the first spring 602, and the second Eight first jacking blocks 604 are symmetrically connected front and back to the top of a movable plate 603, and the space between the jacking blocks 604 is even. Connected, the sleeve rod 605 passes through the upper opening of the rack 401, the sleeve rod 605 cooperates with the rack 401, and the middle of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com