Run-through shaft assembly capable of realizing power separation

A power separation and through-shaft technology, which is applied to axles, transmissions, differential transmissions, etc., can solve the inconvenience of after-sales maintenance, the uncontrollable through-shaft assembly, the poor bearing capacity of the through-shaft structure when the power goes to the rear axle, etc. problems, to achieve the effect of convenient after-sales maintenance, high reliability, and large sliding engagement sleeve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

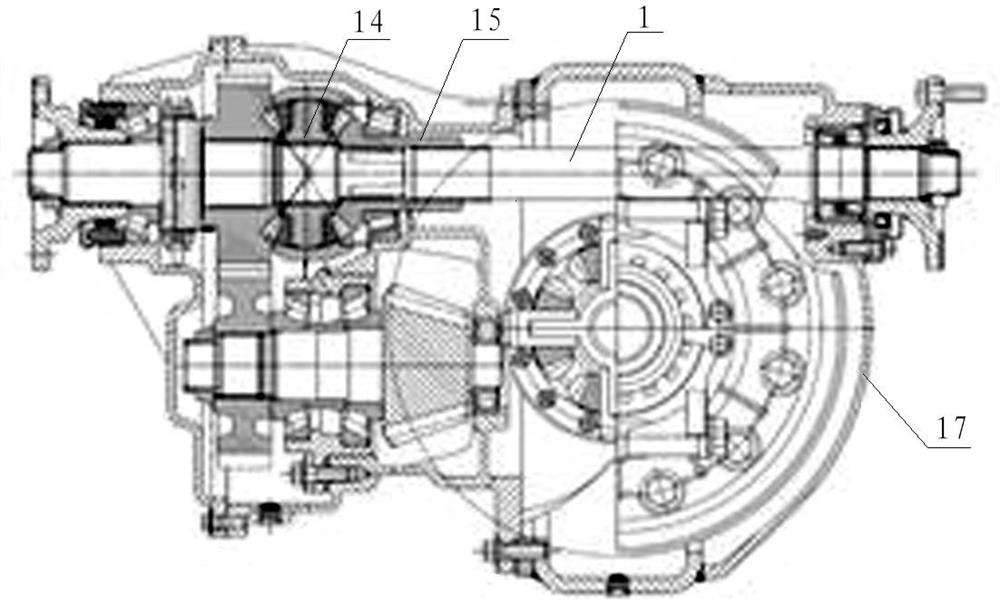

[0024] figure 1 It is a schematic diagram of the through-shaft structure of the mid-axle of an existing conventional double-axle drive vehicle. The through-shaft assembly is connected to the rear axle gear 15 through the spline of the output shaft 1, and the flange at the output end is connected to the output shaft through an internal fixed spline. The input end is output to the rear axle, and the output shaft, the rear axle gear, and the rear axle cannot realize an instant separation state, so the operation that the power of the middle axle is no longer transmitted to the rear axle cannot be realized.

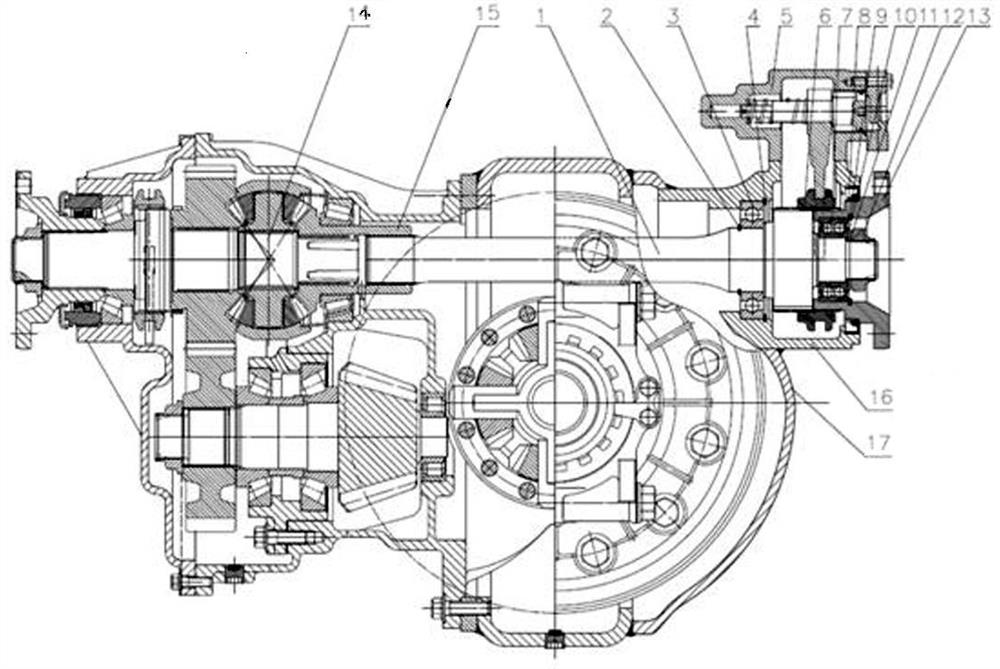

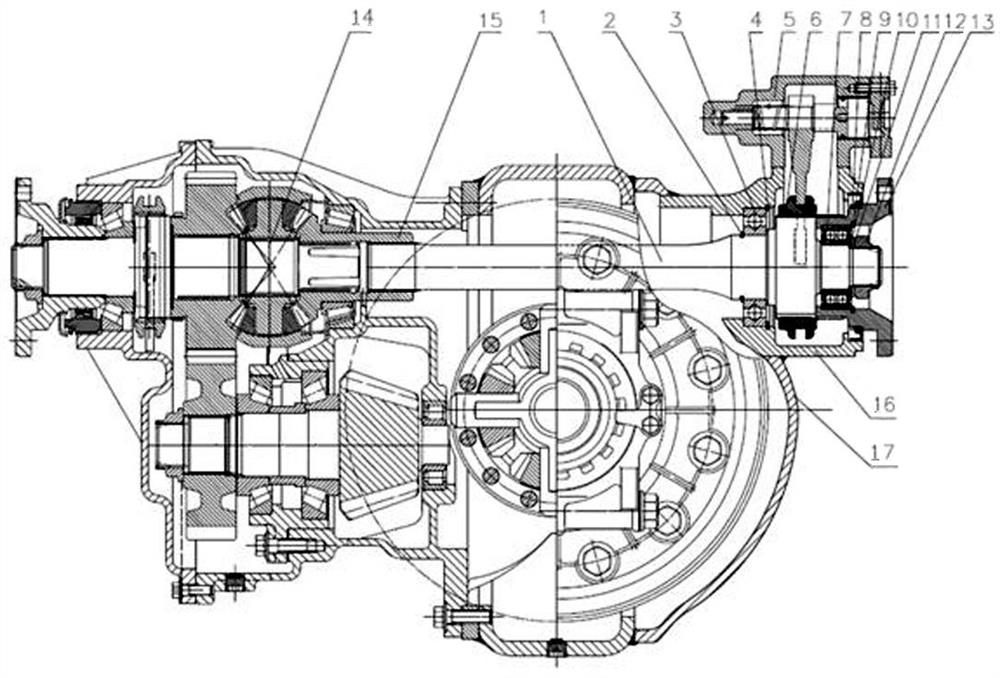

[0025] figure 2 , image 3 with Figure 4 Power separable through shaft assembly, including output shaft 1, retaining ring 2 for shaft, first bearing 3, retaining ring 4 for hole, differential lock 5 with shift fork, sliding engagement sleeve 6, second bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com