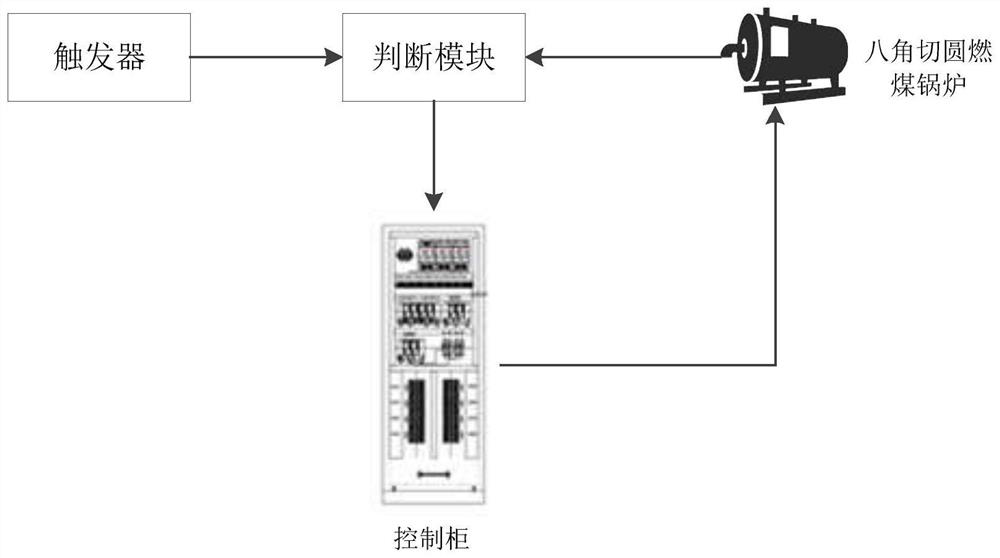

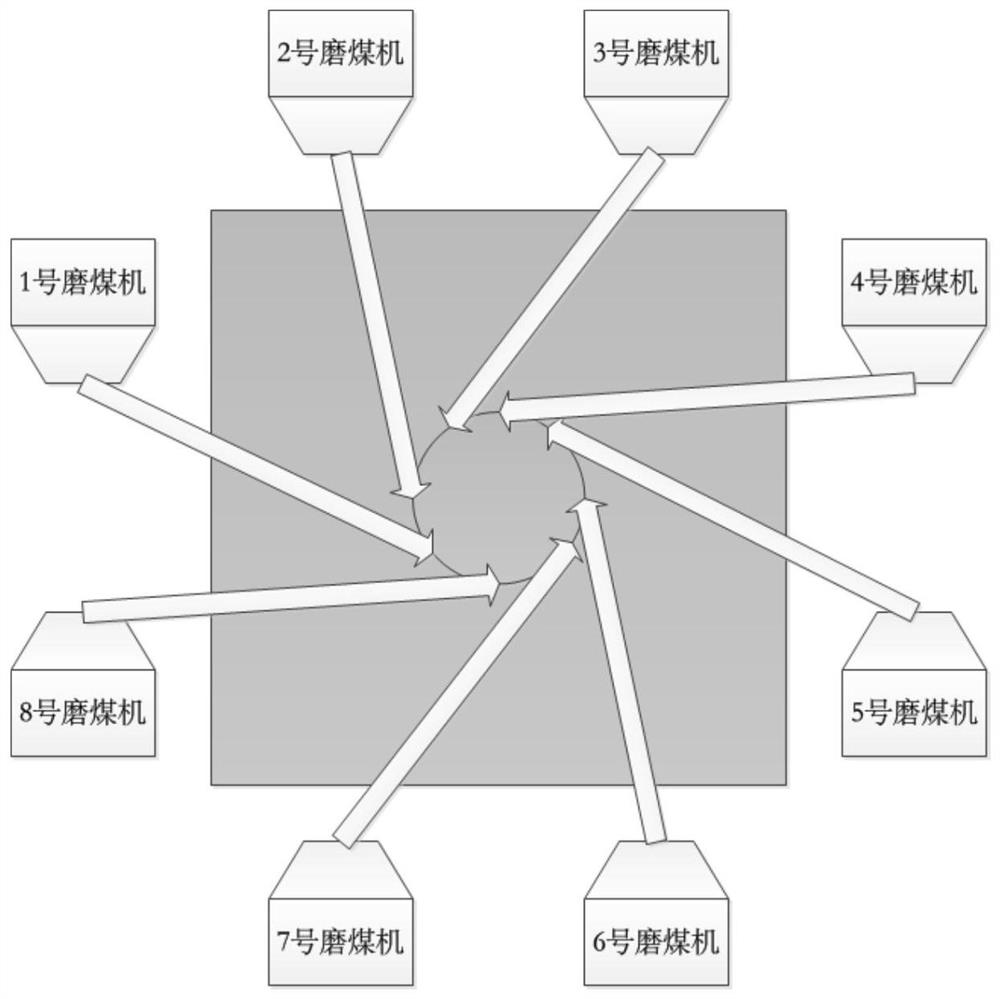

RB (Runback) mill-tripping control device and method for octagonal tangential coal-fired boiler

An octagonal tangential, coal-fired boiler technology, applied in the direction of combustion method, combustion control, fuel supply adjustment, etc., can solve the problems of unable to guarantee the safety of the unit, boiler flame deflection, wall temperature overheating, etc., to achieve fast and safe Boiler heat load, reduce boiler heat load, and ensure stable combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]In order to better understand the technical solution in the present specification, the technical solutions in the present specification are clear and completely described below in conjunction with the drawings in the present specification. The embodiment is merely a part of the embodiments in the present specification, not all of the embodiments. Based on one or more embodiments in this specification, one of ordinary skill in the art will belong to the scope of the present specification embodiments without the presence of creative labor.

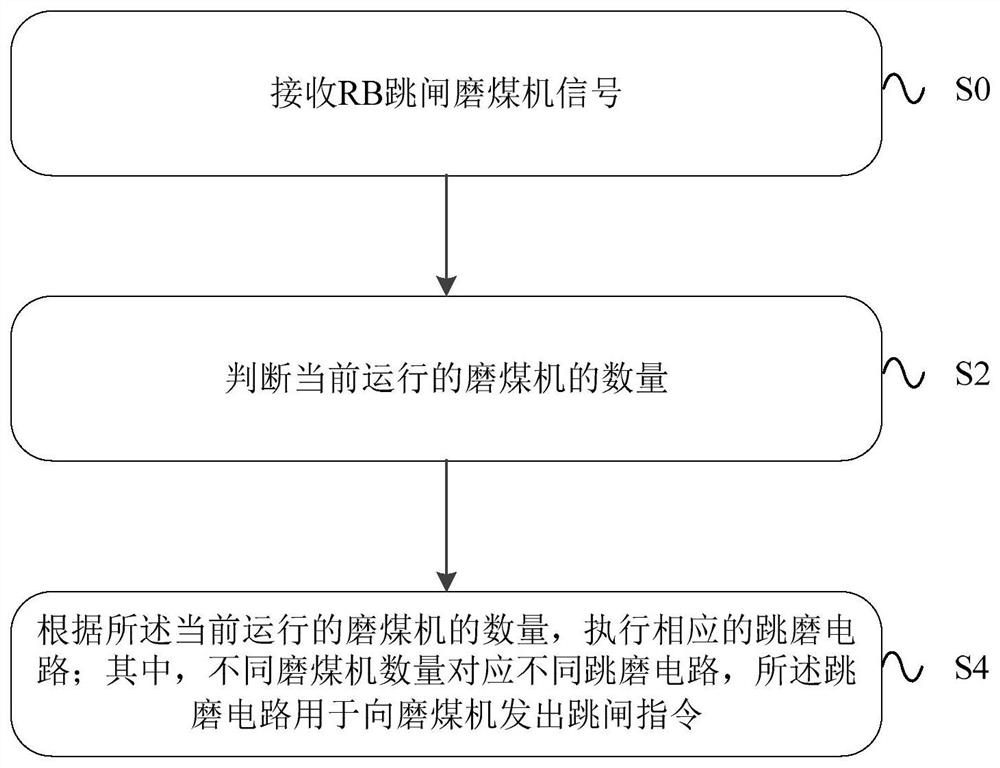

[0016]The main purpose of the RB logic is that when the main auxiliary machine is faulty, it is necessary to quickly reduce the load, and ensure that the main adjustment system is working properly, and the main parameters of the unit are within the allowable range. For the RB function design of the unit, it mainly includes a coal-ranging machine RB, a feed / air blower RB, a fan RB, and a feed pump RB. Usually the RB process requires all the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com