Substrate defect inspection device and method

A defect inspection and substrate technology, which is applied in the field of defect devices, can solve the problems of PCB manufacturing yield reduction, emotional errors, and identification of unqualified PCBs, and achieve the effect of improving yield and maintaining consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

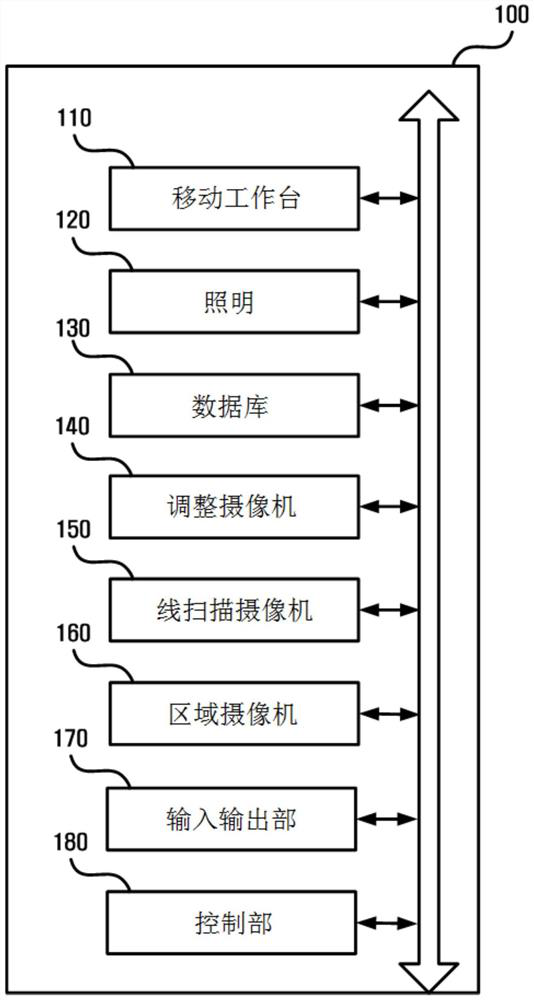

Image

Examples

Embodiment Construction

[0034] Hereinafter, each embodiment will be described in detail with reference to the drawings. The embodiments described below can be modified and implemented in various forms. In order to more clearly describe the features of each embodiment, detailed descriptions of matters known to those of ordinary skill in the art to which each embodiment pertains below are omitted. In addition, in the drawings, parts irrelevant to the description of the respective embodiments are omitted, and similar reference numerals are assigned to similar parts throughout the specification.

[0035] Throughout the specification, when a certain structure is "connected" to another structure, this includes not only the case of "directly connected" but also the case of "connected with other structures interposed therebetween". In addition, when a certain structure "includes" a certain structure, unless otherwise specified, it means that other structures may also be included rather than excluding other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com