High-power-density soldering iron

A high power density, soldering iron technology, applied in the field of soldering iron core, can solve the problems of reducing the size and weight of high-frequency soldering irons, increasing the diameter of the soldering iron tip, increasing the output power, etc., to reduce thermal resistance, avoid temperature overshoot, The effect of shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

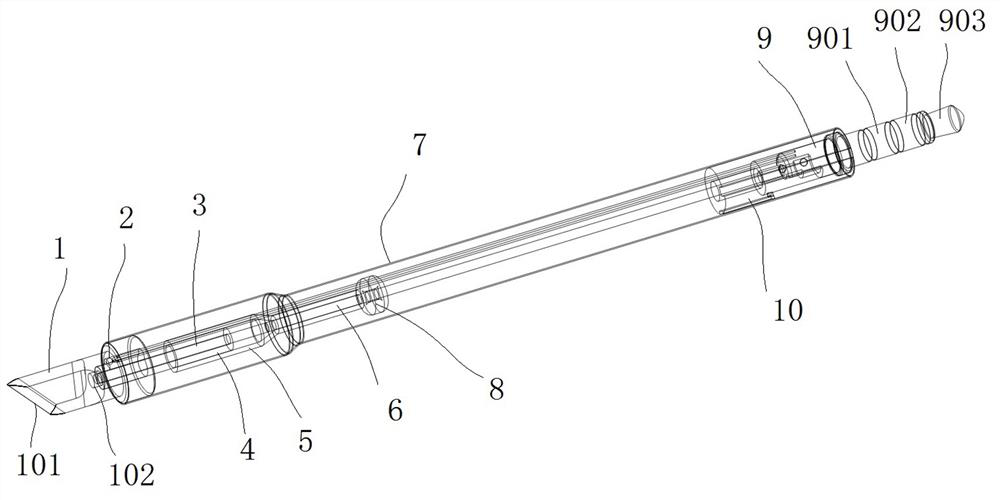

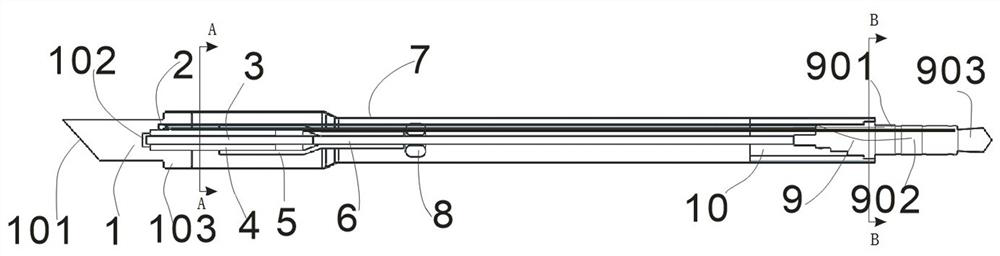

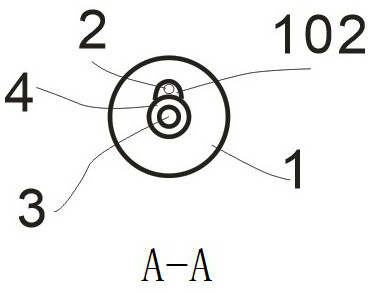

[0029] Such as Figure 1-Figure 4 As shown, the present invention is a high power density soldering iron, which includes a soldering iron head 1, the tail of which is installed on the end of the outer steel pipe 7, and the outer steel pipe 7 has a built-in soldering iron core; the rear end of the soldering iron head 1 is provided with a measuring A temperature sensor 2 and a ceramic tube 4 are installed in the temperature discharge hole 102. The ceramic tube 4 has a built-in discharge needle 3, and the discharge needle 3 is inserted into the temperature measurement discharge hole 102 of the soldering iron tip 1 through the ceramic tube 4.

[0030] The tail end of the outer steel pipe 7 is equipped with a quick-connect plug 9 connected to the built-in socket of the soldering iron handle, and the quick-connect plug 9 is connected with the outer steel pipe 7 through a plastic part 10 .

[0031] The power supply negative terminal 903 of the quick-connect plug 9 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com