Punching tool of asbestos washer for ignition electric nozzle

A technology of asbestos gasket and thermal power, which is applied in metal processing and other directions, can solve the problems of low processing efficiency and achieve the effects of improving processing efficiency, convenient use and operation, and reasonable design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

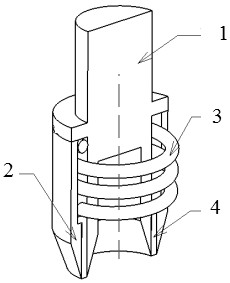

[0025] A punching tool for asbestos gaskets for ignition nozzles, such as Figure 1-Figure 4 As shown, it includes an outer ring cutter 2, an inner ring cutter 1, a spring 3, and a bushing 4; the outer ring cutter 2 is set outside the punching end of the inner ring cutter 1, and the outer ring cutter 2 One end of the inner ring cutter 1 is fixedly connected, and a punching cavity is arranged between the outer ring cutter 2 and the inner ring cutter 1, and the width of the punching end of the punching cavity is the same as the thickness of the asbestos gasket 5; A bushing 4 is slidably arranged inside the punching chamber, and the bushing 4 is connected to the top of the punching chamber through a spring 3. The inner side of the outer ring cutter 2 is provided with a limit device corresponding to the bushing 4 to prevent the bushing 4 from Sliding out of the punching cavity, the sliding stroke of the bushing 4 is greater than or equal to the height of the asbestos washer 5 .

...

Embodiment 2

[0029] This embodiment is optimized on the basis of embodiment 1, such as Figure 5-Figure 8 As shown, the inner side of the outer ring cutter 2 is provided with a limit step along the circumferential direction, the bush 4 extends between the outer ring cutter 2 and the inner ring cutter 1 and a limit receiving platform is correspondingly provided. The limit receiving platform on the top of the bushing 4 can be stuck on the inner limit step of the outer ring cutter 2 .

[0030] Further, the bushing 4 is a tubular structure, and the thickness of the bottom of the bushing 4 is equal to the thickness of the asbestos washer 5 .

[0031] The present invention has reasonable design structure and convenient operation. When processing the asbestos washer 5, the sheet material of the asbestos washer 5 can be punched into an annular washer at one time. Pop-up, improve processing efficiency.

[0032] Other parts of this embodiment are the same as those of Embodiment 1, so details are n...

Embodiment 3

[0034] This embodiment is optimized on the basis of embodiment 1 or 2, as figure 1 As shown, the punching ends of the outer ring cutter 2 and the inner ring cutter 1 are flush. The inner ring cutter 1, the outer ring cutter 2 and the bushing 4 are all made of die steel and prepared through quenching-tempering treatment; the spring 3 is made of spring 3 steel wire and subjected to low-temperature tempering to eliminate stress get. The inner ring cutter 1, the outer ring cutter 2 and the bushing 4 are all made of mold steel, and the strength and wear resistance of the mold are improved after quenching and tempering. The spring 3 is made of spring 3 steel wire and tempered at low temperature. Stress relief, dimensional and elastic stability.

[0035] Other parts of this embodiment are the same as those of Embodiment 1 or 2 above, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com