Plate gluing and pressing device for furniture processing

A technology of laminating device and plate, which is applied in the direction of adhesive application device, device for coating liquid on the surface, veneer press, etc., can solve the problems of affecting processing efficiency, slow natural drying rate of glue, etc. Improve the effect of holding glue and improving heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

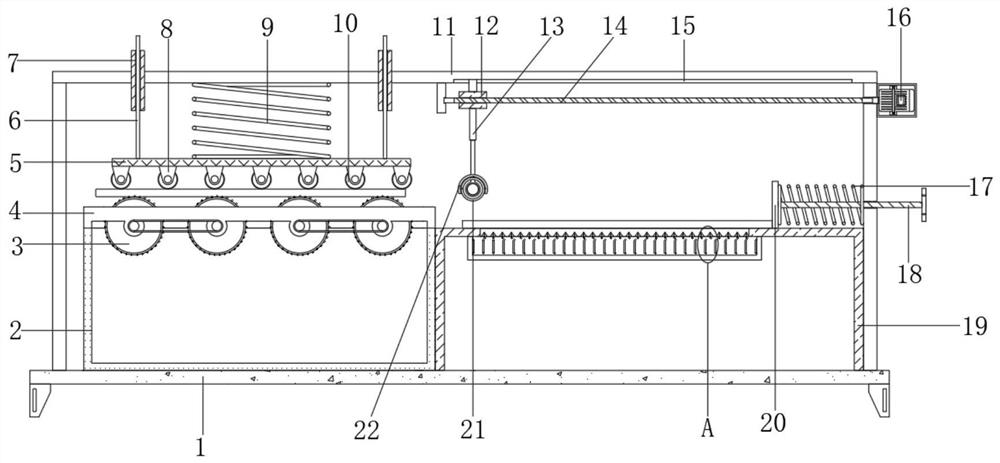

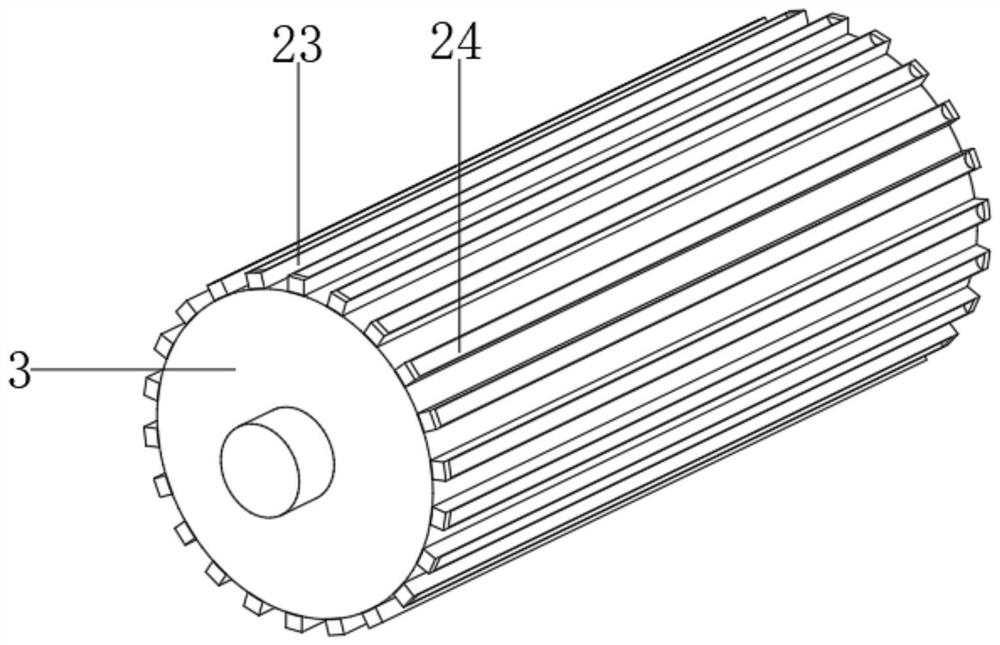

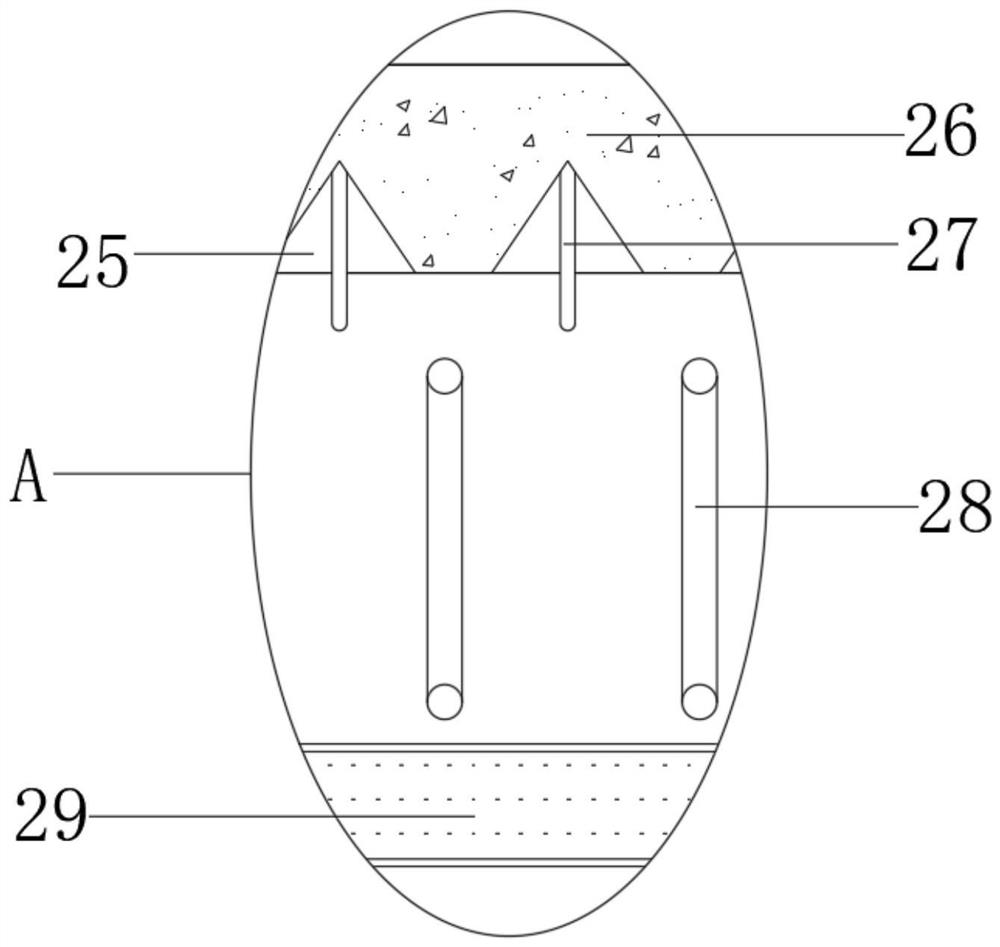

[0030]Refer toFigure 1-4, A plate gluing and pressing device for furniture processing, comprising a base 1 and a top plate 11. One end of the top outer wall of the base 1 is fixed with a glue box 2 through bolts, and the top outer wall of the glue box 2 is fixed with a mounting frame 4 through bolts. , The mounting frame 4 is connected to the sizing roller 3 distributed equidistantly through the bearing rotation, and the circumferential outer wall of the sizing roller 3 is fixedly installed with the convex strips 23 distributed equidistantly and annularly, and one side of the convex strip 23 is provided with an arc-bottomed concave The slot 24 and the top plate 11 are respectively equipped with a material-receiving mechanism and a pressing mechanism, and the pressing mechanism includes a threaded screw 14, one end of the threaded screw 14 is connected with a servo motor 16 through a coupling, and the threaded screw 14 One end of the outer wall is threaded with the moving block 12, t...

Embodiment 2

[0041]ReferenceFigure 5 , A gluing and pressing device for sheet metal for furniture processing. Compared with the first embodiment, this embodiment further includes that the inner wall of the cavity of the pressing roller 21 is welded with spiral fins 32.

[0042]When the present invention is in use: when in use, the spiral fins 32 arranged on the inner wall of the pressure roller 21 are used to effectively increase the heating area of the pressure roller 21, improve the heat exchange effect, and further increase the heating and heating rate of the pressure roller 21 itself to achieve further The purpose of improving glue drying efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com