Strip-breaking type wire drawing forming equipment for surface of plastic product

A wire-drawing forming and product technology, applied in the coating and other directions, can solve problems such as poor quality of finished products, and achieve the effect of accelerating wire-drawing forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

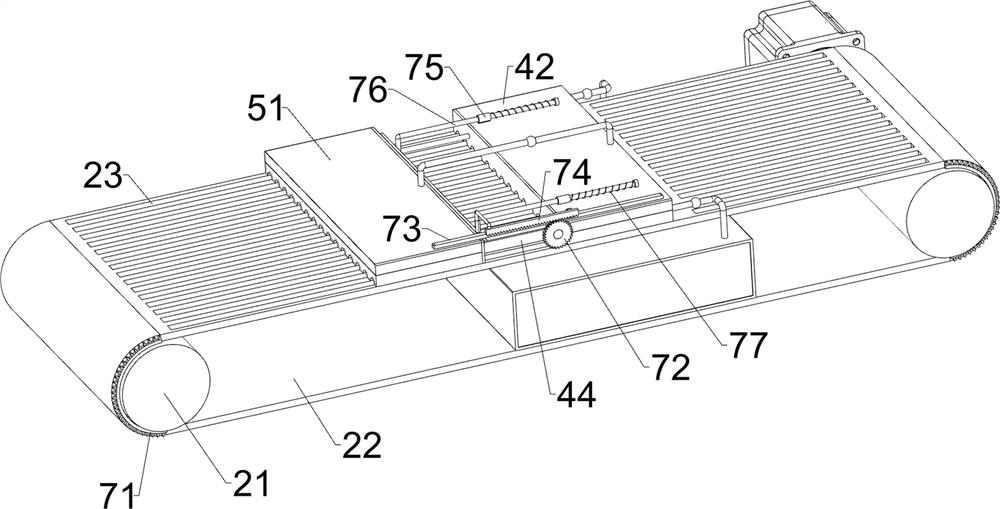

[0031] A shredded wire drawing forming equipment for the surface of plastic products, such as Figure 1-3 As shown, it includes a support 1 , a conveying assembly 2 and a blanking forming assembly 3 , the conveying assembly 2 is provided on the upper side of the support 1 , and the blanking forming assembly 3 is provided on the left upper side of the support 1 .

[0032] When it is necessary to carry out wire-drawing molding on the surface of plastic products, start the conveying component 2, and then the raw material will enter the conveying component 2 from the blanking forming component 3, and the conveying component 2 will perform wire-drawing on it. When all plastic products When drawing and forming, close the conveying assembly 2.

[0033] Conveyor assembly 2 comprises rotating wheel 21, conveyer belt 22 and deceleration motor 24, and the left and right sides of support 1 are all rotatably connected with rotating wheel 21, and conveyer belt 22 is connected between rotati...

Embodiment 2

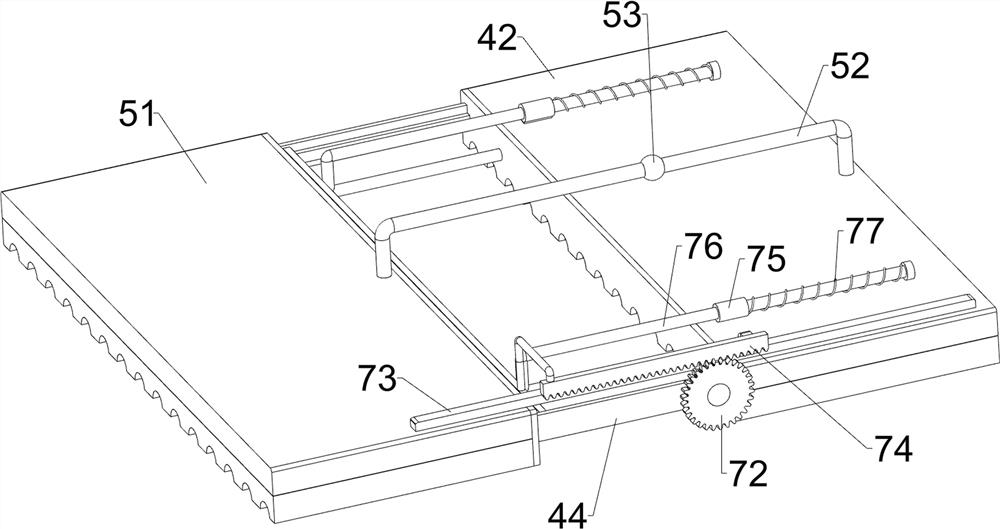

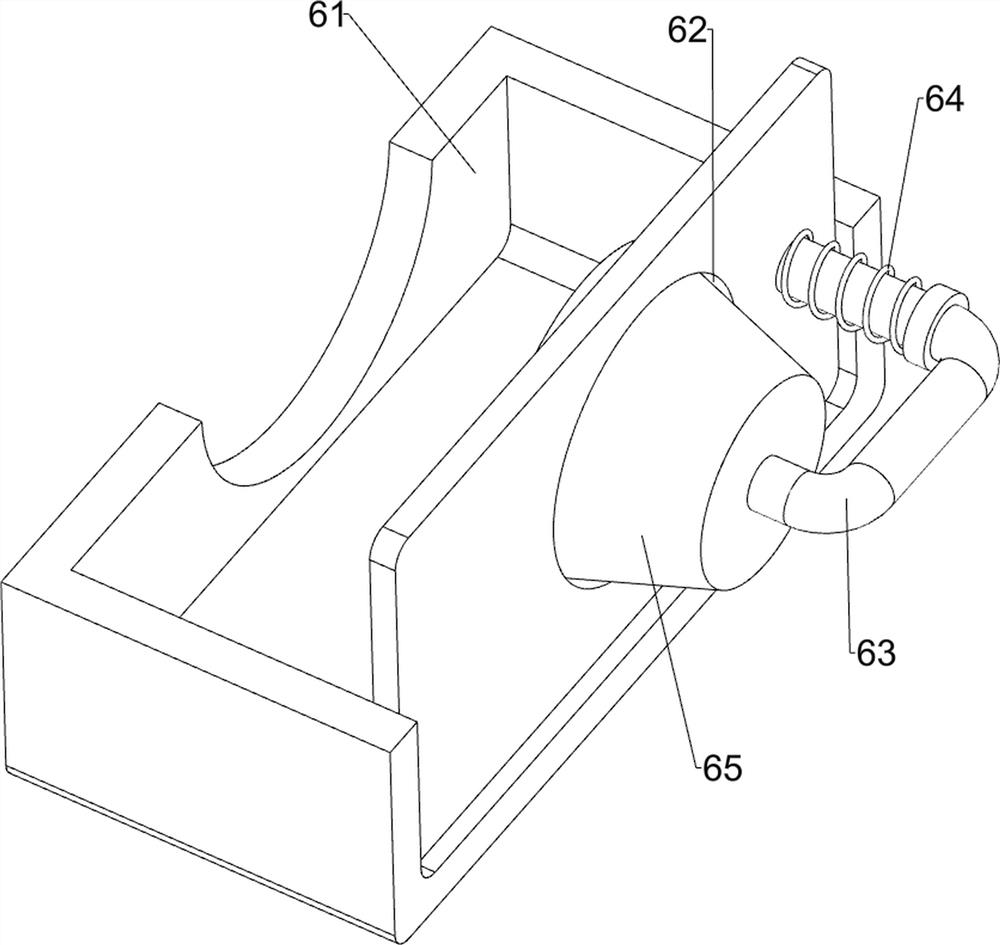

[0038] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a first water cooling assembly 4 is also included, and the first water cooling assembly 4 includes a water storage tank 41, a first cooling tank 42, a first connecting pipe 43, a first sliding rail 44, a sliding plate 45, a sliding rod 46 and a piston plate 47. A water storage tank 41 is connected to the upper side of the middle part of the bracket 1, and the first connecting pipe 43 is connected to the upper, front, and rear sides of the water storage tank 41, and the first cooling tank 42 is connected between the first connecting pipes 43, and the first cooling tank 42 The first slide rail 44 is connected to the front and rear sides of the first slide rail 44, and a slide plate 45 is slidably connected between the first slide rails 44, and a slide bar 46 is connected to the front and rear sides of the left part of the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com