Metal-plastic composite film and its preparation method and application

A technology of metal-plastic and composite film, which is applied in applications, other household appliances, and metal layered products, etc., which can solve the problems of prone to errors and omissions, waste of stacking time, and many layers of stacking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

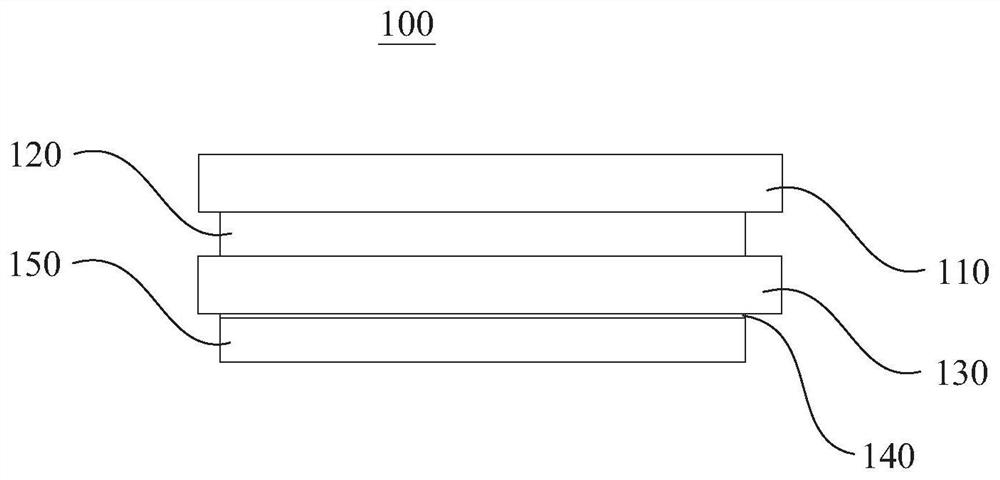

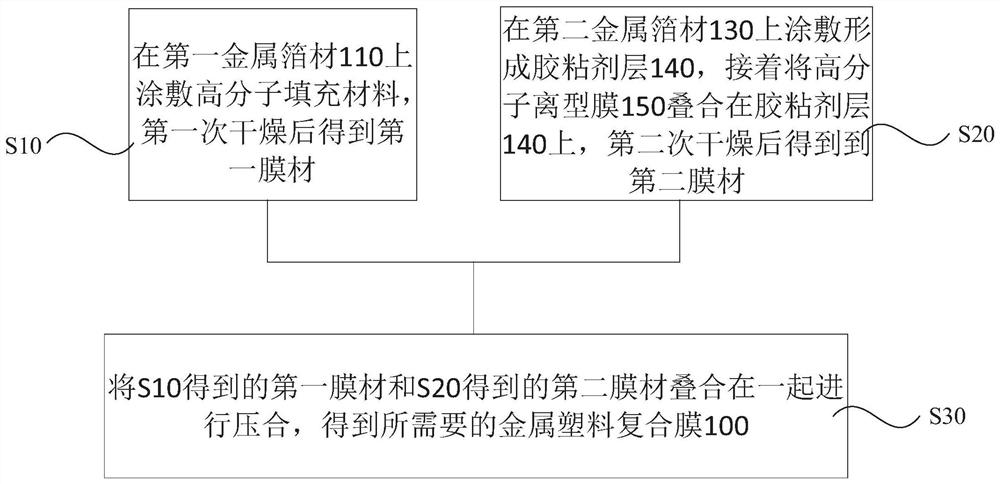

[0018] Such as figure 2 The metal-plastic composite film 100 shown in one embodiment includes a first metal foil 110 , a polymer filled film 120 , a second metal foil 130 , an adhesive layer 140 and a polymer release film 150 stacked in sequence.

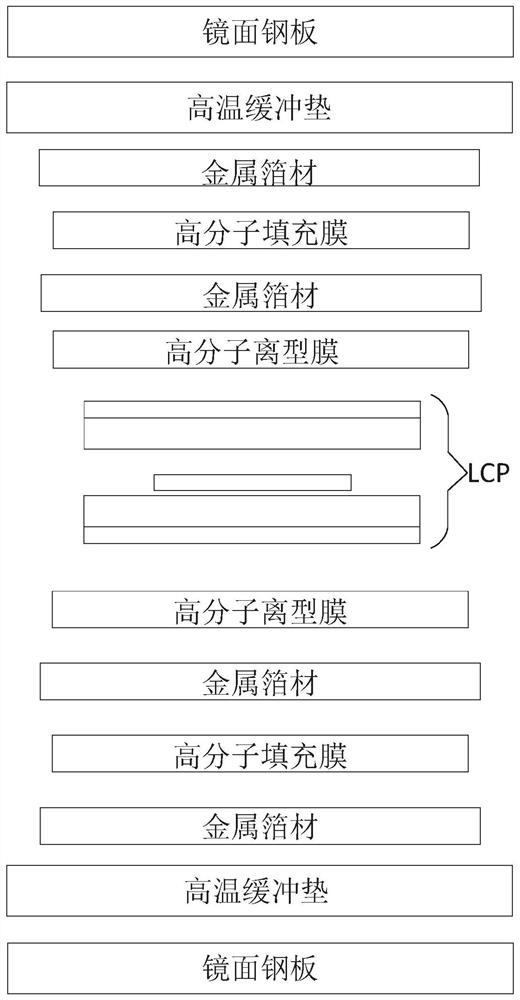

[0019] The metal-plastic composite film 100 includes a first metal foil 110 , a polymer filled film 120 , a second metal foil 130 , an adhesive layer 140 and a polymer release film 150 stacked in sequence. combine figure 1 When the metal-plastic composite film 100 is applied to the preparation of LCP substrates, it is only necessary to provide the metal-plastic composite film 100, the high-temperature buffer pad, and the mirror steel plate as three pressing auxiliary materials, which greatly reduces the number of stacked layers of auxiliary materials, thereby reducing errors and omissions and Save stacking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com