Toughened glass thermal insulation coating and preparation method thereof

A heat-insulating coating and heat-insulating layer technology, applied in glass manufacturing equipment, coatings, glass tempering, etc., can solve problems such as unevenness, affecting heat insulation effect, coating cracking, etc., and achieve enhanced scratch resistance And weather resistance, reduce the probability of fragmentation or self-explosion, good effect of dispersing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a temperable glass heat-insulating coating in this embodiment includes the following preparation steps:

[0032] (1) Calcium acetate is dissolved in silica sol (solid content is 20%, particle diameter is 10~20nm), and the addition amount of calcium acetate is respectively controlled to contain SiO in silica sol 2 5%, 12%, 16% and 20% of the mass to obtain the precursor solution of the porous thermal insulation layer.

[0033] (2) Coat the porous insulation layer precursor solution in step (1) on the surface of the glass substrate, raise the temperature to 160-180°C for heating and curing for 15 minutes, then send it to the tempering furnace and keep it at 680-700°C for 5 minutes, then The temperature is lowered to below 80° C. within 3 minutes to obtain tempered glass with a porous heat-insulating layer.

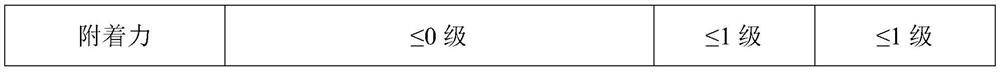

[0034] (3) coating the heat-insulating coating on the surface of the porous heat-insulating layer in step (2), and curing it to obtain a tempe...

Embodiment 2

[0048] A method for preparing a temperable glass heat-insulating coating in this embodiment includes the following preparation steps:

[0049] (1) Calcium acetate is dissolved in silica sol (solid content is 20%, particle diameter is 10~20nm), and the addition amount of calcium acetate is controlled to be SiO contained in silica sol 2 12% of the mass to obtain the precursor solution of the porous thermal insulation layer.

[0050] (2) Coat the precursor solution of the porous insulation layer in step (1) on the surface of the glass substrate, raise the temperature to 180-200°C for heating and curing for 10 minutes, then send it to the tempering furnace and keep it at 700-720°C for 6 minutes, then The temperature is lowered to below 80° C. within 3 minutes to obtain tempered glass with a porous heat-insulating layer.

[0051] (3) coating the heat-insulating coating on the surface of the porous heat-insulating layer in step (2), and curing it to obtain a temperable glass heat-i...

Embodiment 3

[0056] A method for preparing a temperable glass heat-insulating coating in this embodiment includes the following preparation steps:

[0057] (1) Calcium acetate is dissolved in silica sol (solid content is 10%, particle diameter is 10~50nm), and the addition amount of calcium acetate is controlled to be SiO contained in silica sol 2 16% of the mass to obtain the precursor solution of the porous thermal insulation layer.

[0058] (2) Coat the porous insulation layer precursor solution in step (1) on the surface of the glass substrate, raise the temperature to 180-200°C for heating and curing for 20 minutes, then send it to the tempering furnace and keep it at 700-720°C for 5 minutes, then The temperature is lowered to below 80° C. within 2 minutes to obtain tempered glass with a porous heat-insulating layer.

[0059] (3) coating the heat-insulating coating on the surface of the porous heat-insulating layer in step (2), and curing it to obtain a temperable glass heat-insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com