Finishing production process of lavender scent type automobile leather

A production process, lavender technology, is applied in the field of lavender-scented automotive leather finishing production process, which can solve the problem of bad smell of leather, and achieve the effect of reducing bad smell and slow and controllable release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of finishing production process of lavender-scented automobile leather

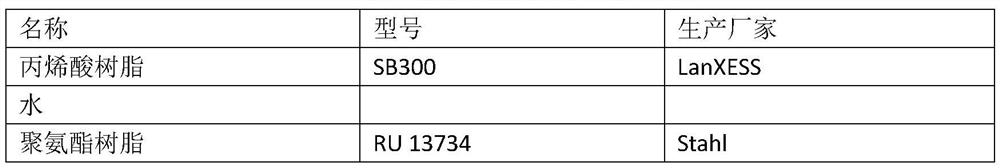

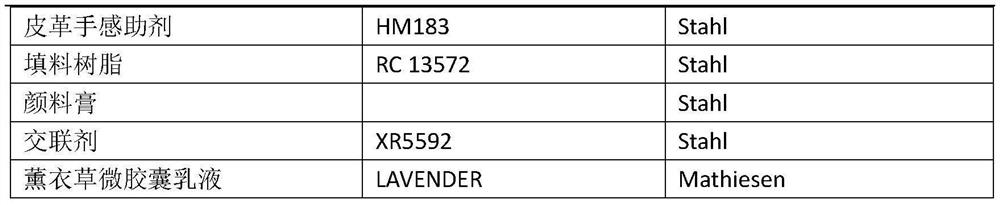

[0057] The Perlnappa FOC Soul low-odor leather blank production process of the selected Perlnappa FOC Soul low-odor leather blank production process for the finishing production process of the lavender-scented automobile leather in this embodiment is as follows:

[0058] Wet white skin peeling→weighing→returning water→retanning→neutralization→filling and dyeing→fatliquoring→color fixing→washing→drum and horse riding→vacuum drying→hanging to dry→softening→vibrating;

[0059] (1) Squeeze and shave the wet white skin: the thickness range is controlled at 1.1-1.3mm;

[0060] (2) Weighing: Weigh the wet white skin after being evenly shaved in the same batch, and this weight is used as the standard for the amount of subsequent chemicals.

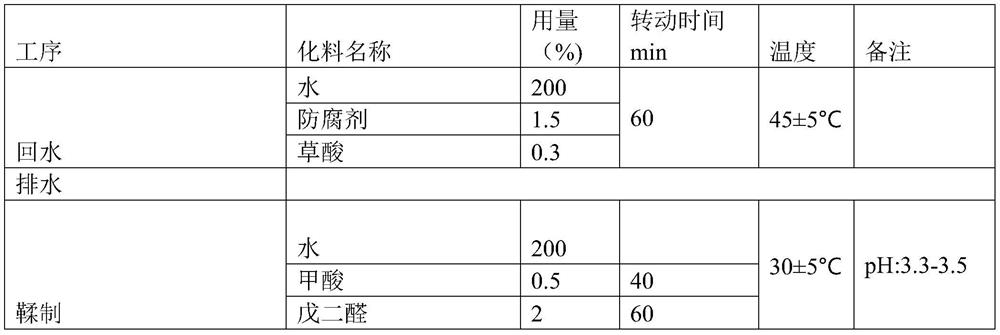

[0061] (3) Backwater: use the tanning drum to make the wet white leather fully absorb water, open the gaps between the leather fibers, and facilitate the full ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com