A kind of high-density pearlite steel rail and its preparation method

A technology of pearlite and steel rails, which is applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of precise control of heating furnace and heat treatment control that do not involve composition control, and achieve the effect of improving strength and toughness indicators and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

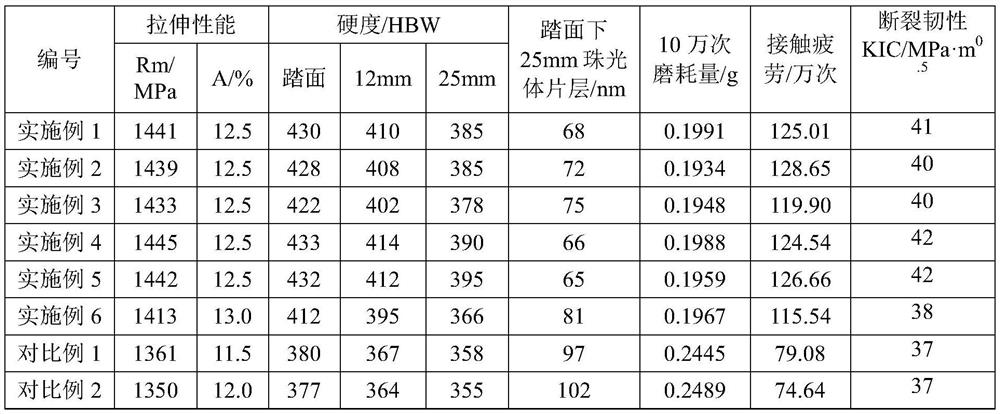

Examples

Embodiment 1

[0063] The invention is used to explain the preparation method of the steel rail with high-density pearlite structure.

[0064] Furnace material is smelted into molten steel through converter smelting or electric furnace smelting, aluminum-free deoxidation, LF refining, RH vacuum treatment or VD vacuum treatment, continuous casting of molten steel into billets, heating of billets in heating furnace, high-pressure water dephosphorization, and online rolling of billets into rails , on-line heat treatment, straightening, flaw detection and processing;

[0065]The heating of the billet into the heating furnace includes a preheating stage, a heating stage and a soaking stage. The preheating time of the preheating stage is 50 minutes, and the temperature in the furnace is 610 ° C; the heating time of the heating stage is 100 minutes, and the temperature in the furnace is 1000 ° C ; The soaking time in the soaking stage is 40 minutes, and the temperature in the furnace is 1175°C;

...

Embodiment 2

[0069] Furnace material is smelted into molten steel through converter smelting or electric furnace smelting, aluminum-free deoxidation, LF refining, RH vacuum treatment or VD vacuum treatment, continuous casting of molten steel into billets, heating of billets in heating furnace, high-pressure water dephosphorization, and online rolling of billets into rails , on-line heat treatment, straightening, flaw detection and processing;

[0070] The heating of the billet into the heating furnace includes a preheating stage, a heating stage and a soaking stage. Among them, the preheating time of the preheating stage is 30 minutes, and the temperature in the furnace is 700 ° C; the heating time of the heating stage is 130 minutes, and the temperature in the furnace is 950 ° C ; The soaking time in the soaking stage is 30 minutes, and the temperature in the furnace is 1225°C;

[0071] The on-line heat treatment includes air cooling the rail with residual heat after final rolling to 780°...

Embodiment 3

[0074] Furnace material is smelted into molten steel through converter smelting or electric furnace smelting, aluminum-free deoxidation, LF refining, RH vacuum treatment or VD vacuum treatment, continuous casting of molten steel into billets, heating of billets in heating furnace, high-pressure water dephosphorization, and online rolling of billets into rails , on-line heat treatment, straightening, flaw detection and processing;

[0075] The heating of the billet into the heating furnace includes a preheating stage, a heating stage and a soaking stage. Among them, the preheating time of the preheating stage is 80 minutes, and the temperature in the furnace is 540 ° C; the heating time of the heating stage is 160 minutes, and the temperature in the furnace is 1150 ° C ; The soaking time in the soaking stage is 50 minutes, and the temperature in the furnace is 1150°C;

[0076] The on-line heat treatment includes air cooling the rail with residual heat after final rolling to 840...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com