Processing method of wear-resistant anti-aging rope net wire

A line processing and anti-aging technology, applied in the direction of fiber chemical characteristics, yarn, conjugated synthetic polymer artificial filament, etc., can solve the problem that high-density polyethylene cannot meet the needs of processing, poor aging resistance, dependence on imports, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

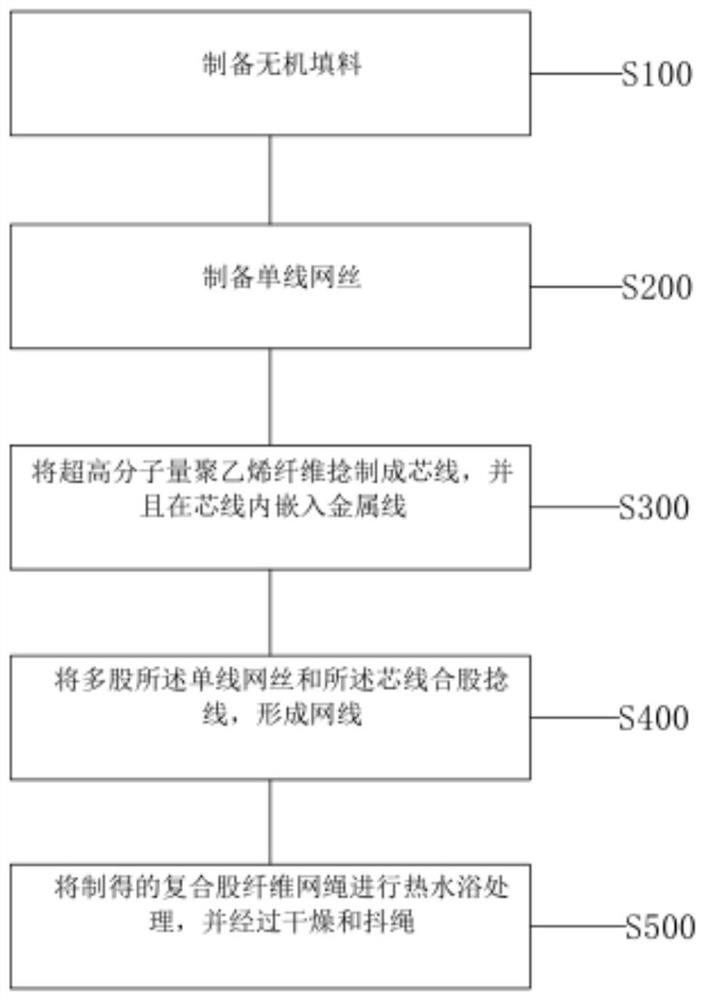

[0016] The invention provides a wear-resistant and anti-aging rope net wire processing method, see figure 1 , including the following steps:

[0017] Step S100, mixing cetyl dihydroxyethyl amine oxide, dodecyl dimethyl amine oxide, and ethanol solution according to the set mass ratio, after mixing for a predetermined time, adding ammonia water, and collecting the filtrate after filtering to obtain inorganic filler;

[0018] Step S200, mixing and stirring the inorganic filler, rubber, and polyethylene particles to produce a mixed material; preparing a single wire mesh based on the mixed material;

[0019] Step S300, twisting the UHMWPE fiber into a core wire, and embedding a metal wire in the core wire;

[0020] Step S400, plying and twisting multiple strands of the single wire mesh and the core wire to form a mesh wire.

[0021] In step S400, when compound twisting, the braiding angle is 40°-55°, and the tension value is a first preset value.

[0022] Step S500, subjecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com