Large-span deck type concrete-filled steel tube arch bridge

A steel tube concrete and long-span technology, applied in arch bridges, bridges, truss bridges, etc., can solve the problems that cannot meet the requirements of strength, stiffness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a long-span concrete-filled steel tube arch bridge, which is applied on a canyon, that is, the concrete-filled steel tube arch bridge in this embodiment is a valley-spanning bridge.

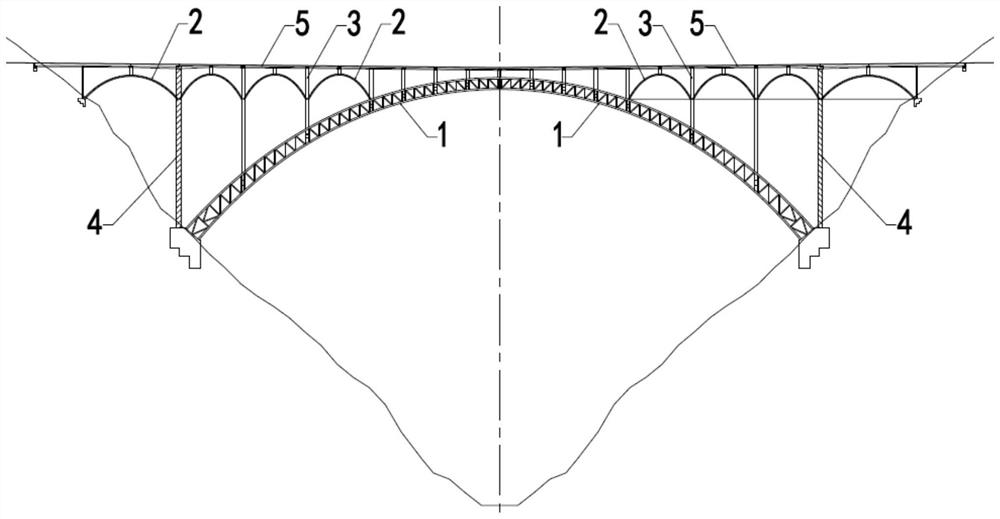

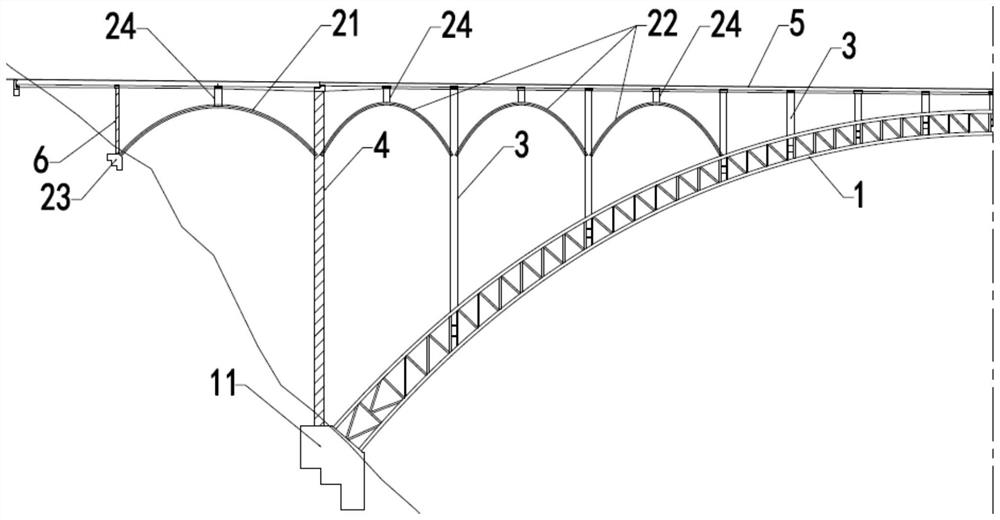

[0040] Such as figure 1 and figure 2 As shown, the concrete-filled steel tube arch bridge includes a main arch 1 , a main arch abutment 11 , an abdominal arch 2 , an abdominal arch abutment 23 , an upper column 3 of the main arch arch, a junction pier 4 and a deck beam 5 .

[0041] Described main arch abutment 11 is provided with two, and is respectively arranged on the foundation of canyon both sides, and described main arch 1 is arranged between described main arch abutment 11 on both sides and is formed by the main arch abutment 11 for support. In this embodiment, the main arch 1 adopts a steel pipe concrete truss structure as an example, the deck beam 5 is arranged on the main arch 1, and the deck beam 5 connects both sides of the canyon, thereby forming a c...

Embodiment 2

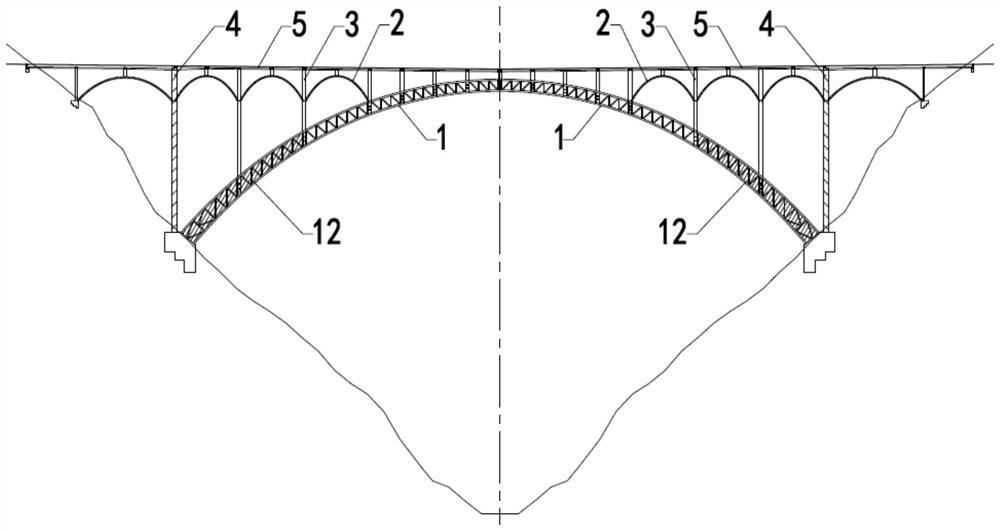

[0052] Such as image 3 , Figure 4 and Figure 5 As shown, on the basis of Embodiment 1, further, in this embodiment, the arch foot of the main arch 1 is provided with a stiffening area 12, and the abdominal tube of the main arch 1 of the stiffening area 12 is provided with Stiffened steel plate 121. Specifically, the web tubes between the corresponding upper chord 111 and lower chord 112 of the main arch 1 include oblique web tubes 114 and transverse web tubes 113, and the oblique web tubes 114 and transverse web tubes in the stiffening area 12 113, the upper chord 111 and the lower chord 112 are surrounded by several closed triangular frames arranged vertically, and a stiffening steel plate 121 is welded along the inner edge of the closed triangular frame. Through this arrangement, the bearing capacity of the main arch 1 of the stiffening area 12 is significantly improved.

[0053]On both sides of the main arch 1, since the upper pillars 3 of the main arch at the foot o...

Embodiment 3

[0057] Such as Figure 6 and Figure 7 As shown, on the basis of Embodiment 2, further, in the concrete-filled steel tube arch bridge described in this embodiment, the abdominal arch 2 is connected with tie rods 7, and the tie rods 7 are stretched on the abdominal arch 2 Among them, specifically, there are multiple tie rods 7 and they are connected to the abdominal arches 2 respectively. In this embodiment, the tie rods 7 are existing conventional steel strand tie rods. The purpose of setting the tie rods 7 is that the abdominal arch 2 can generate a horizontal thrust to the connected upper column 3 of the main arch, the main arch 1 or the junction pier 4 . In order to eliminate the influence of the horizontal thrust, we set the tie rod 7 at the abdominal arch 2, and balance the main arch 1, which is connected to the abdominal arch 2, by setting the tension of the tie rod 7. The horizontal thrust caused by the column 3 or the junction pier 4 on the main arch.

[0058] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com