Reinforcement reinforcement method and system for foundation anchor bolts of power transmission tower

A technology for transmission towers and anchor bolts, applied in the field of transmission tower foundations, can solve the problems of repairing cracks and cannot fundamentally suppress cracks, and achieves the effect of inhibiting lateral development, good force transmission, and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

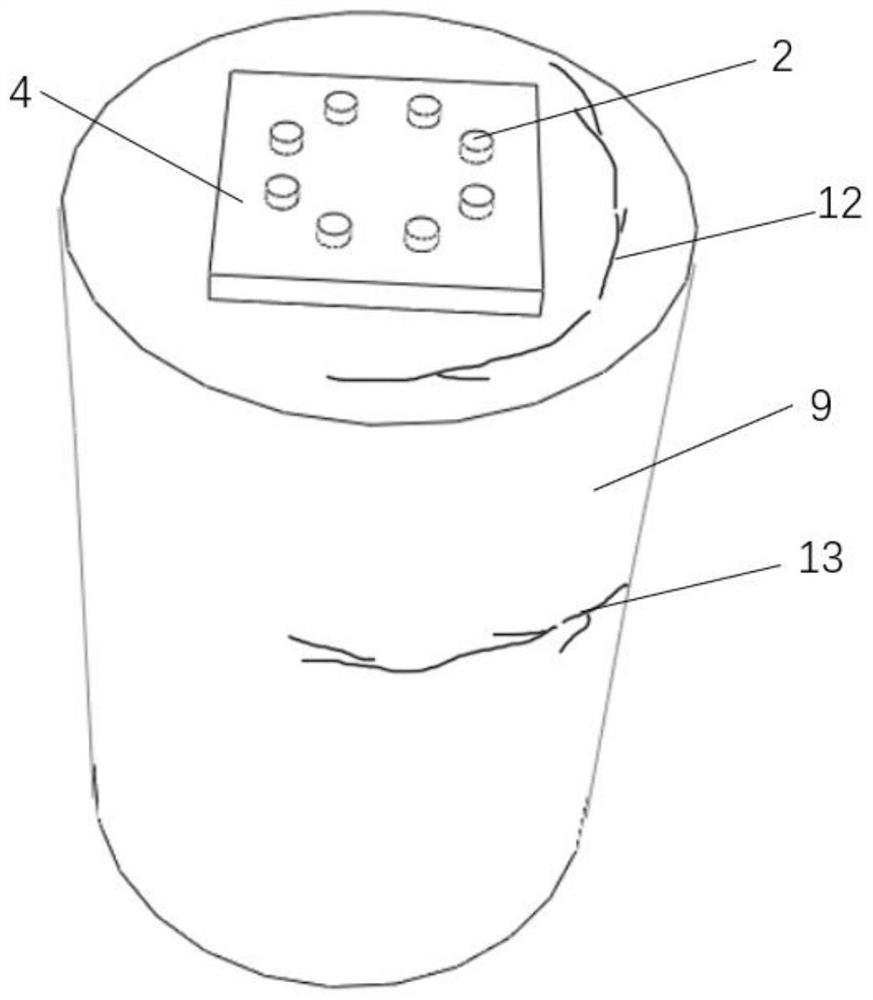

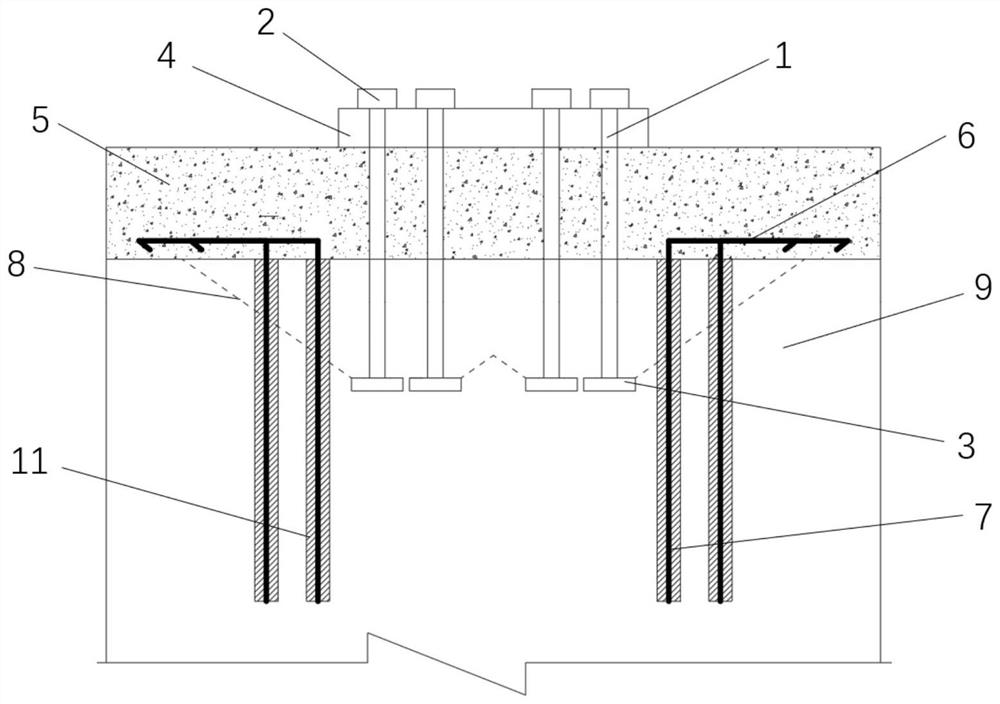

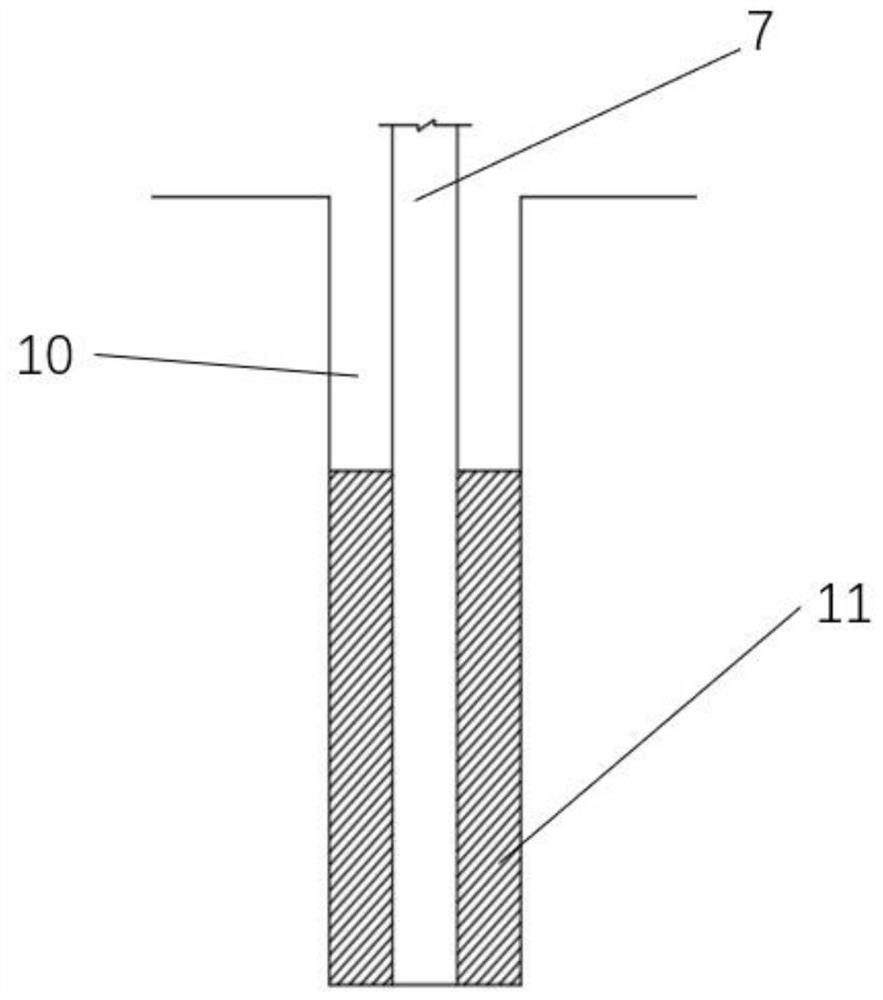

[0038] Such as Figure 1-Figure 4 As shown, a reinforcement system for the foundation anchor bolt of a transmission tower includes a concrete pile foundation 9, and the center of the concrete pile foundation 9 is provided with a plurality of anchor rods 1 in the axial direction, and the plurality of anchor rods 1 form an anchor bolt group, the bottom of the anchor rod 1 is provided with an anchor plate 3, the top of the anchor rod 1 passes through the through hole on the backing plate 4 of the anchor bolt group, the top of the anchor rod 1 is tightened by a nut 2, and includes Several L-shaped steel bars, several L-shaped steel bars are evenly arranged in two circles around the anchor bolt group, and the L-shaped steel bars include mutually perpendicular steel bar horizontal sections 6 and steel bar vertical sections 7. Extend and insert into the channel 10 in the concrete pile foundation 9, the channel 10 is filled with epoxy resin glue 11, the vertical section 7 of the steel...

Embodiment 2

[0047] Such as Figure 1-Figure 4 As shown, this embodiment is based on Embodiment 1. When there is an annular crack 12 on the pile foundation upper surface in the concrete pile foundation 9, the concrete on the top of the concrete pile foundation 9 is excavated first, and then the concrete pile foundation 9 is drilled along the axial direction. The hole forms a channel 10, and then the vertical section 7 of the steel bar is arranged in the channel 10, and the top of the concrete pile foundation 9 is backfilled to form a backfilled concrete 5, and the horizontal section 6 of the steel bar is embedded in the backfilled concrete 5.

[0048] This embodiment is applicable to when the concrete pile foundation 9 has an annular crack 12 on the upper surface of the pile foundation and an annular crack 13 on the side of the pile foundation, the construction method includes the following steps:

[0049] S1, excavate the upper surface concrete of the concrete pile foundation 9 according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com