Bare wall electromechanical wire box reinforcing method

A wire box and wall machine technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problem of affecting the quality pass rate and visual quality of wire boxes, reducing work efficiency, displacement and box quality. Internal leakage and other problems, to achieve the effect of safe and reliable project quality, simple reinforcement structure, and reduce project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

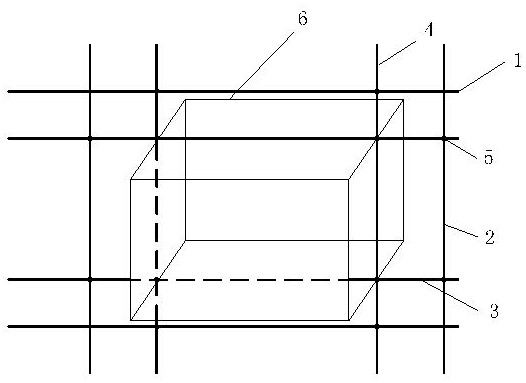

[0024]The method for reinforcing the wire box of the clear water wall machine of the present invention, by using round steel for reinforcement, includes the following steps:

[0025]Step 1: Collect φ6mm round steel heads from the steel bar processing area, and cut different lengths according to actual needs. Prepare the wire box, electric welding machine, welding rod, and laser level; determine the axis position of the wire box according to the design drawings, use the laser level to locate, and mark the actual size of the junction box 6.

[0026]Step 2: Prepare the tools. Use a cutting machine to cut the φ6mm round steel according to the required length. The cut length is based on the spacing between the longitudinal and transverse steel bars of the shear wall on site, and the appropriate length is selected to ensure that the round steel crosses the structural steel bars, so that the wire box can be firmly fixed.

[0027]Step 3: When preparing to fix the wire box, communicate with the civil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com